What Are Drill Bits?

Drill Bits for sale are cutting tools attached to the end of a drill string. Their main function is to break through soil, rock, and other materials during borehole drilling. In water well drilling, drill bits are responsible for forming the borehole that eventually reaches the underground water layer.

The bit rotates at high speed and exerts axial force to chip, grind, or crush the formation. Drill fluid or compressed air often accompanies the process to clear cuttings and cool the bit. Choosing the right bit significantly improves efficiency and lowers overall costs.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Water Well Drill Bit Types

When exploring Drill Bits for Sale, it’s important to understand the different types available for water well drill bit applications. Each type serves different terrains and drilling methods.

By Drilling Method

- Rotary Drilling Bits: Common for water wells, these bits grind formations using rotation and downward pressure.

- Percussion Bits: Used in impact drilling systems to crush rock through repeated blows.

- Down-the-Hole (DTH) Bits: Attached to pneumatic hammers, ideal for hard formations and deep boreholes.

By Structure

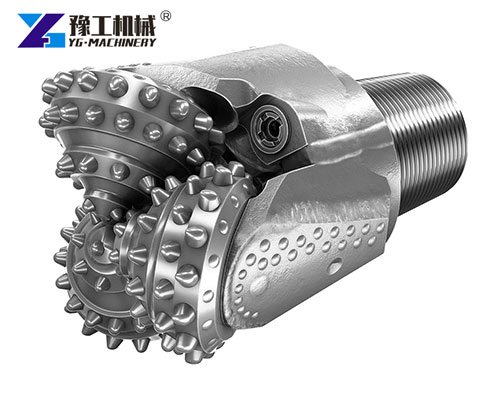

- Tricone Roller Bits: Feature three rotating cones with steel or tungsten teeth. Best for mixed formations.

- PDC (Polycrystalline Diamond Compact) Bits: Ideal for hard rock and long-lasting performance.

- Drag Bits: Simple design with fixed blades, suitable for soft soils and clay.

- Step-Type Bits: Often used in low-cost shallow boreholes for soft-medium formations.

Each bit type serves a specific purpose and must align with both geological and rig conditions.

Function and Benefits of Using the Right Drill Bit

A properly selected drill bit improves productivity, extends tool life, and enhances borehole accuracy. Key functions include:

- Cutting Through Geological Layers: From soft clay to hard granite, bits are engineered to penetrate specific materials.

- Maintaining Borehole Direction: Precision in drilling ensures vertical or angled boreholes remain on track.

- Removing Cuttings: Bit design helps circulate fluid or air, pushing debris out of the borehole.

- Reducing Equipment Wear: Sharp, strong bits reduce vibration and torque resistance.

A quality drill bit minimizes bit replacement frequency and ensures smooth drilling progress.

Buying Guide: Choosing the Right Drill Bits for Sale

When evaluating Drill Bits for Sale, consider several key factors that impact performance and cost-effectiveness.

- Formation Hardness: Match bit type and tooth material to geological conditions (e.g., PDC for hard rock, drag bits for soft clay).

- Drilling Method: Choose based on rig capabilities—rotary, DTH, or percussion.

- Bit Size: Select a diameter compatible with the borehole design and casing size.

- Thread Connection: Ensure compatibility with drill rods and tools.

- Bit Life and Maintenance: Higher-quality bits last longer and reduce downtime.

- Budget Considerations: While cheap bits may save upfront costs, they often lead to more frequent replacements.

Correct selection improves overall drilling efficiency and project profitability.

Applications of Water Well Drill Bits

Water well drill bit products are versatile and used in a wide range of drilling environments:

- Residential Water Wells: Commonly use tricone or drag bits depending on the region.

- Agricultural and Irrigation Wells: Often require larger boreholes, making DTH or PDC bits more suitable.

- Industrial Boreholes: Deep and demanding projects benefit from premium-grade bits with reinforced cutting structures.

- Geothermal Drilling: Similar to water wells, but may require higher thermal and impact resistance.

- Exploration Projects: Bits must deliver clean cuts and accurate paths for sampling.

The right water well drill bit ensures optimal borehole condition and longevity of the well.

Frequently Asked Questions About Drill Bits

- Q1: What is the average lifespan of a drill bit?

A: It depends on the formation type and bit quality, ranging from several days to weeks in operation. - Q2: Can I use the same bit for different drilling projects?

A: Not recommended. Match the bit to the soil or rock type for each project to ensure safety and efficiency. - Q3: Are used bits worth considering?

A: For shallow or low-cost wells, refurbished bits may be suitable. For commercial projects, new bits are more reliable. - Q4: How do I know the bit is worn out?

A: Common signs include slow penetration rate, irregular borehole diameter, and increased rig vibration. - Q5: Is bit regrinding or sharpening possible?

A: Yes, especially for certain steel-toothed bits. However, diamond and tungsten inserts typically aren’t reusable.

Drill Bit Manufacturer: Why Choose YG Machinery

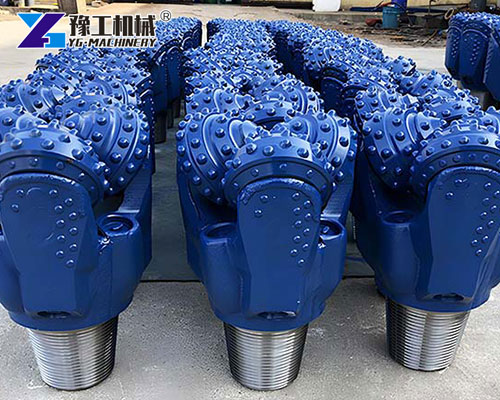

As a trusted Drill Bit Manufacturer, YG Machinery supplies a wide range of Drill Bits for Sale tailored for different soil conditions and drilling technologies. Our products are widely used in water wells, mining, and geothermal applications.

YG Machinery Advantages:

- High-Quality Materials: Including tungsten carbide, PDC inserts, and heat-treated steel.

- Precision Engineering: Each bit is CNC-machined for perfect balance and thread alignment.

- Customization Options: Sizes, threads, and blade configurations can be adjusted per project need.

- Technical Support: Experts provide on-site and remote consultation for bit selection and maintenance.

When quality, efficiency, and longevity matter, YG Machinery stands out as a dependable drill bit manufacturer for professionals around the globe.

WhatsApp/WeChat/Phone: 86 138 3715 9132