The Egg Tray Making Machine meets growing demand for eco-friendly packaging. Many buyers move away from plastic and foam. Paper egg trays are recyclable and low-cost. Small farms and big factories both use this machine. The market for egg carton production lines keeps growing. This machine gives a fast return on investment. It also helps reduce plastic waste.

WhatsApp/WeChat/Phone: 86 138 3715 9132

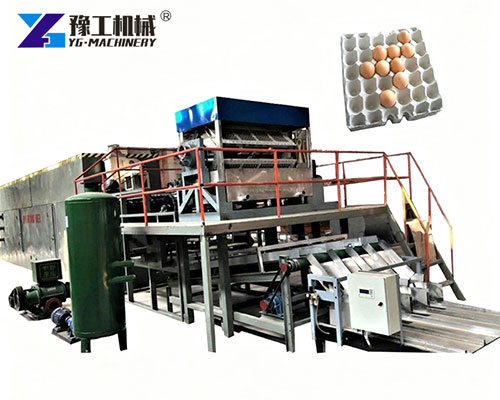

What Is An Egg Tray Making Machine (Egg Carton Machine)

An egg carton machine makes trays from waste paper. The main steps are: pulp making, molding, drying, and packing. The machine uses water and a pump to form pulp. A vacuum mold shapes the tray. The tray is then dried in a dryer. Finally, the trays are stacked and packed. This process is also called the egg carton making process or pulp molding production line. The whole line can run for many hours with a few workers.

Technical Specifications Of Paper Egg Tray Production Line

Here are common models and specs. This table helps you compare quickly.

| Model | Output(pcs/h) | Mould Quantity | Total Power(kW) | Raw Materials (kg/h) |

| DT-1*3 | 1000 | 1*3+3 | 41 | 23.8 |

| DT-1*4 | 1500 | 1*4+4 | 41 | 28.4 |

| DT-3*4 | 2000 | 3*4+3 | 53.7 | 32.57 |

| DT-4*4 | 3000 | 4*4+4 | 57 | 39.9 |

| DT-4*8 | 4000 | 4*8+4 | 90 | 63 |

| DT-5*8 | 5000-6000 | 5*8+5 | 150 | 105 |

| DT-5*12 | 6000-7000 | 5*12+5 | 153 | 107.1 |

These numbers change by pulp quality and dryer size. Tell us your daily target, and we will match the right egg tray equipment.

Applications Of Egg Tray Machine And Egg Tray Equipment

Egg tray equipment is not only for eggs. It has wide use in many fields:

- Egg trays and egg cartons for farms and stores.

- Fruit trays and produce trays for markets.

- Coffee cup trays and drink holders.

- Protective inner packing for electronics.

- Eco-friendly gift boxes and molded packaging.

This paper egg tray production line helps companies replace plastic. It supports green packaging and adds product value.

Why Choose Our Automatic Egg Tray Machine (Paper Tray Machine)

Our automatic egg tray machine has strong features for buyers:

- High Automation: Feeding, molding, and stacking are automatic.

- Low Energy Use: Efficient pumps and dryers save power.

- Custom Molds: Make 6, 12, 18, or 30-egg tray shapes.

- Easy to Operate: PLC and touch screen control.

- Stable Quality: Good tray strength and low waste.

This egg tray machine suits small and large plants. We also offer a full paper tray machine package with dryer and pulp system.

Production Process Of Egg Carton Production Line

The egg carton production line (Pulp Molding Production Line) follows clear steps:

- Waste Paper Sorting: Remove plastic and ink.

- Pulp Making: Soak and beat the paper until it becomes pulp.

- Molding: Vacuum molds shape the pulp into trays.

- Dewatering: Remove water by pressing or airflow.

- Drying: Use a tunnel dryer or a rack dryer to harden trays.

- Stacking and Packing: The Automatic stacker stacks trays for packing.

This pulp molding production line keeps water use low and recycles paper. The egg carton-making process is simple to learn.

Market Demand And Investment Return (ROI)

Paper trays have a strong market demand today. Reasons to invest:

- Many countries ban foam and reduce plastic.

- Egg sellers need cheap and eco trays.

- You can sell trays to farms, shops, and packers.

A small machine can pay back in months. A medium or large paper egg tray production line gives steady profit. Costs depend on dryer type, capacity, and local labor.

Why Choose YG Egg Tray Making Machine (Egg Tray Equipment Supplier)

YG Machinery offers strong support as an egg tray equipment supplier and maker:

- Factory Direct Price: Lower cost than buying through agents.

- Many Models: From small to full egg carton production lines.

- Custom Molds: Make your brand shape and logo on trays.

- After-Sales Service: Installation, training, and spare parts.

- Export Experience: We work with clients worldwide and follow export rules.

We are a trusted paper tray production line manufacturer, and we help new businesses start fast.

Simple Tips For Startups And Operators

When you start a line, keep these tips in mind:

- Use clean waste paper for better pulp.

- Adjust pulp concentration for tray strength.

- Keep the dryer temperature stable.

- Train workers on mold change and maintenance.

- Plan water recycling to save costs.

Good start-up steps help you get better trays and less waste.

If you want an Egg Tray Making Machine, contact YG Machinery today. Tell us your target output and product types. We will offer a free plan and price for the best egg tray equipment. Fast delivery, custom molds, and full training are ready. Start your paper egg tray production line now and join the green packaging market.

WhatsApp/WeChat/Phone: 86 138 3715 9132