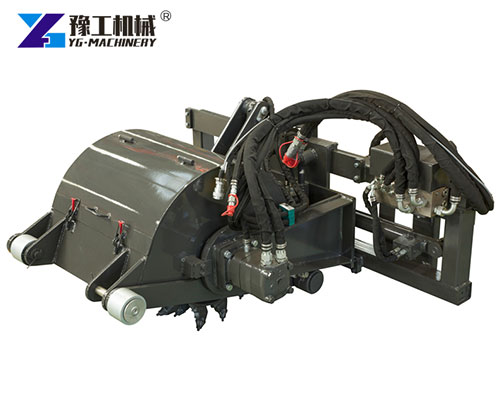

An Excavator Milling Attachment is a highly specialized tool designed to mount on the boom of an excavator, converting it into a precision surface milling machine. It consists of a rotating drum equipped with cutting teeth that grind, plane, or mill surfaces such as concrete, asphalt, rock, and compacted soil.

The attachment is driven by the excavator’s hydraulic system, allowing operators to achieve controlled material removal in applications where accuracy and surface finish are critical.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of Excavator Milling Attachment

| Parameter | 140 | 180 | 240 | 350 |

| Engine displacement | 398ml/r | 1340ml/r | 2099 ml/r | 4198ml/r |

| Speed range | 0-100 r/min | 0-120 r/min | 0-85 r/min | 0-140 r/min |

| Max Pressure | 40Mpa | 35Mpa | 35Mpa | 45Mpa |

| Max power | 22KW | 50KW | 65KW | 120KW |

| Cutter head | 22-44pcs | 44-68pcs | 48pcs | 76pcs |

| Height | 650mm | 830mm | 1420mm | 1450mm |

| Width | 400-500mm | 500-780mm | 1000mm | 1100mm |

| Diameter | 390mm | 470-500mm | 620mm | 690mm |

| Weight | 200KG | 600KG | 1650KG | 1700KG |

| (excavator weight) | 3-8T | 10-20T | 20-30T | 30-50T |

Key Features Of Milling Head For Excavator

A quality Milling Head for Excavator offers several important features that enhance performance and usability:

- Heavy-Duty Drum: Equipped with replaceable carbide teeth for long-lasting cutting ability.

- Variable Speed Control: Adjusts drum rotation to match material hardness and desired cutting depth.

- Robust Housing: Protects internal components and ensures safe operation in tough environments.

- Precision Mounting: Engineered for a stable connection to a wide range of excavators.

- Minimal Vibration: Designed to reduce stress on both the machine and the operator.

These features ensure consistent results and high productivity when using an Excavator Milling Attachment.

Applications Of Excavator Hydraulic Milling Cutter

An Excavator Hydraulic Milling Cutter is suitable for a wide range of tasks across multiple industries. Common applications include:

- Concrete Surface Preparation: Milling and smoothing concrete surfaces for repair or resurfacing.

- Road Maintenance: Removing damaged asphalt layers and preparing roadbeds.

- Rock Profiling: Milling rock surfaces in construction or mining applications.

- Tunnel and Trench Work: Shaping surfaces and walls with precision in confined spaces.

- Utility Installation: Milling narrow trenches for pipes and cables.

The flexibility of the Excavator Milling Attachment makes it an essential tool for contractors working in varied and demanding conditions.

Advantages Of Using Milling Attachment For Excavators

Equipping your machine with a Milling Attachment for Excavator offers numerous operational advantages:

- Increased Versatility: Expands your excavator’s capabilities beyond digging and lifting.

- Precise Material Removal: Achieves controlled depth and surface finish with minimal operator effort.

- Cost-Effective: Reduces the need for dedicated milling equipment.

- Minimized Downtime: Fast setup and simple operation improve jobsite efficiency.

- Safe Operation: Eliminates the need for manual chipping or cutting in hazardous environments.

These benefits help contractors complete projects faster and with better quality results.

Hydraulic Drum Cutter Vs. Excavator Milling Machine: Key Differences

While the Hydraulic Drum Cutter and Excavator Milling Machine may appear similar, they serve different purposes. Here’s a breakdown:

| Aspect | Hydraulic Drum Cutter | Excavator Milling Machine |

|---|---|---|

| Primary Use | Profiling rock surfaces and demolition | Precision surface milling |

| Cutting Mechanism | Dual rotating drums with teeth | Single rotating drum with teeth |

| Material Focus | Primarily rock and concrete demolition | Asphalt, concrete, and surface preparation |

| Appearance | Compact, robust housing with two visible drums | Larger single drum with protective shroud |

| Work Principle | Fractures and removes material with drum rotation | Grinds and planes the material for a smooth finish |

Choosing between a Hydraulic Drum Cutter and an Excavator Milling Machine depends on whether the application requires aggressive demolition or fine milling work.

Why Choose YG Machinery For Excavator Milling Attachment

YG Machinery is a trusted name in Excavator Milling Attachments, offering proven solutions for contractors worldwide. Here’s why YG is the preferred choice:

- Proven Engineering: Each attachment is designed for maximum durability and consistent performance.

- Custom Solutions: We offer attachments compatible with a wide range of excavator sizes and brands.

- Competitive Pricing: Our products deliver superior value with excellent return on investment.

- Full Support: YG provides comprehensive pre-sale consultation and after-sale service to ensure customer satisfaction.

- Innovative Design: Our Excavator Milling Attachments feature the latest in cutting and control technology for exceptional results.

With YG, you get a reliable tool backed by years of engineering expertise and customer focus.

WhatsApp/WeChat/Phone: 86 138 3715 9132