The excavator quick coupler is a high-efficiency tool that allows operators to switch between different attachments, like buckets, breakers, or grapples, without manual pin removal. Designed for convenience, safety, and speed, this coupler system is a must-have for construction professionals aiming to reduce downtime and increase equipment versatility.

By minimizing manual labor and tool-switching time, the quick coupler helps job sites run faster and more efficiently, particularly in industries like construction, demolition, landscaping, and utility work.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Excavator Quick Coupler Parameter

| Item/Model | Unit | YGMINI | YG45 | YG50/55 | YG60/65 | YG70/80 | YG90 | YG100/110 |

| Suitable Excavator | ton | 1.5-4 | 4-7 | 5-8 | 9-19 | 17-23 | 23-30 | 33-45 |

| Weight | kg | 25 | 50-60 | 80 | 120-130 | 280-290 | 420-430 | 450-580 |

| Length | mm | 388 | 534-545 | 600 | 765 | 924-944 | 983-1050 | 1006-1473 |

| Height | mm | 246 | 307 | 310 | 388 | 492 | 574 | 558-610 |

| Width | mm | 175 | 258-263 | 270-280 | 353-436 | 449-483 | 543-568 | 606-663 |

| Pin-to-Pin Center Distance | mm | 80-150 | 230-270 | 290-360 | 380-420 | 460-480 | 473-540 | 550-620 |

| Forearm Open Width | mm | 80-140 | 155-170 | 180-200 | 232-315 | 306-340 | 375-411 | 416-469 |

| Retractable Distance of Oil Cylinder | mm | 170-206 | 205-275 | 340-450 | 340-486 | 256-390 | 413-590 | 520-590 |

| Top-to-Bottom Pin Distance | mm | 159 | 195 | 195 | 220 | 275 | 300 | 360 |

| Pin Diameter | mm | 25-40 | 45-50 | 50-55 | 60-70 | 70-80 | 80-90 | 90-120 |

| Working Pressure | bar | 32-40 | 32-40 | 32-40 | 32-40 | 32-40 | 32-40 | 32-40 |

| Working Flow | Ipm | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

Applications: Versatility Across Multiple Job Sites

The excavator quick coupler is widely used in both light and heavy-duty excavating tasks. Its value lies in its ability to perform quick swaps, enabling operators to handle multiple tasks without changing machines or interrupting workflow.

It is ideal for:

- Earthmoving and trenching

- Demolition and recycling

- Road construction

- Landscaping and forestry

- Pipeline installation

- Utility work and mining

A single excavator can perform multiple roles throughout the day simply by changing attachments with the coupler.

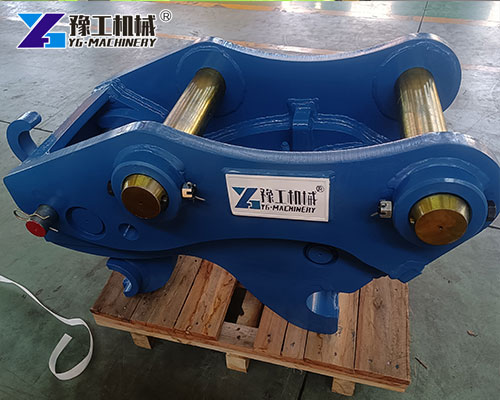

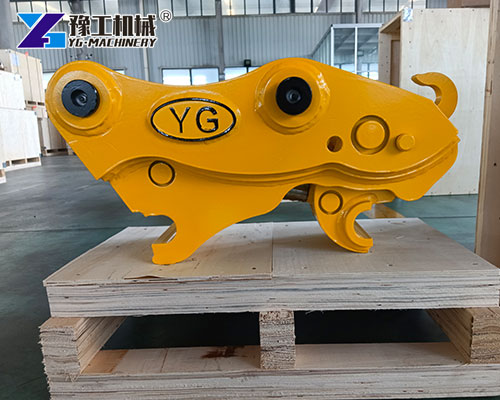

Key Features of the Hydraulic Quick Coupler Excavator

The YG hydraulic quick coupler excavator boasts a range of features designed for durability, safety, and ease of use. These include:

- Robust Construction: Manufactured using high-grade steel for maximum strength and longevity in harsh working environments.

- Hydraulic Locking System: Ensuring a secure and reliable connection between the excavator and the attachment.

- Safety Mechanism: Incorporating features to prevent accidental detachment, safeguarding both personnel and equipment.

- Universal Compatibility: Designed to fit a wide range of excavator brands and models.

- Low Maintenance: Engineered for minimal upkeep, reducing downtime and operational costs.

These features collectively contribute to the exceptional performance and reliability of the YG Excavator Quick Coupler.

Working Principle of a Hydraulic Quick Coupler Excavator

A hydraulic quick coupler excavator uses hydraulic cylinders powered by the excavator’s own system to engage or disengage attachments. Operators can switch tools without leaving the cab, making it ideal for large-scale and fast-paced job sites.

Working principle:

- The operator activates the release mechanism via a cab-mounted control switch.

- Hydraulic pressure unlocks the attachment pin and opens the coupler hook.

- The old attachment is dropped, and the operator repositions the arm to pick up the new tool.

- Hydraulic pressure is used again to close and secure the new attachment.

This system allows for safe, efficient, and seamless transitions between tools in under two minutes.

How to Install a Coupler Excavator System

Installing a coupler excavator system is straightforward and can usually be completed within a few hours, depending on the machine and coupler type. The process varies slightly between manual and hydraulic models.

Basic installation steps include:

- Align Coupler to Arm: Position the quick coupler at the tip of the excavator boom.

- Secure with Pins: Insert and lock mounting pins to secure the coupler to the arm.

- Connect Hydraulic Lines (if applicable): For hydraulic quick coupler excavator systems, attach hoses to the auxiliary hydraulic circuit.

- Install Controls in Cab: Add switch controls for attachment release/lock operation.

- Test for Functionality: Confirm the locking mechanism engages and disengages properly.

Safety checks and pressure calibration should be conducted before field use.

YG’s Expertise in Excavator Attachments Manufacturing

Our Excavator Quick Coupler, CNC-machined for precision, uses wear-resistant steel, ensuring a perfect fit, reliable locking, and long service life. They’re customizable for major brands, with installations worldwide. Plus, we offer professional support from installation to after-sales.

Besides couplers, YG provides a wide range of attachments, including hydraulic breakers, auger drills, and grapples. This variety helps clients optimize their excavators’ value and versatility, making YG their go-to for all excavator accessory needs.

WhatsApp/WeChat/Phone: 86 138 3715 9132