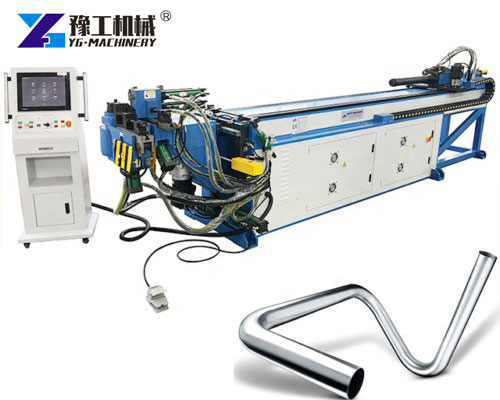

A Full CNC pipe-bending machine is an advanced piece of automation equipment that integrates CNC technology with hydraulic/servo drive systems. This machine is capable of performing complex pipe bending operations in three-dimensional space, enabling continuous bending at multiple radii and angles without frequent die changes. It is highly suitable for industries that require high precision and small-batch production of diverse pipe fittings.

WhatsApp/WeChat/Phone: 86 138 3715 9132

What Is a Full CNC Pipe Bending Machine?

A Full CNC pipe-bending machine is designed to provide precise and flexible bending solutions for various types of pipes, including those used in industries such as aerospace, automotive, and construction. The machine is capable of handling multiple pipe sizes and materials while maintaining high accuracy.

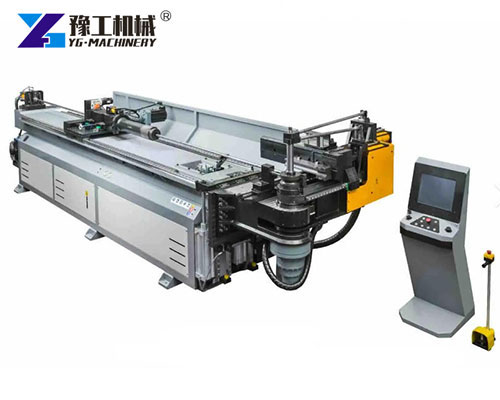

The main components of a CNC pipe bender machine include:

- CNC Controller: Allows for precise programming and control of the bending process.

- Hydraulic or Servo System: Powers the machine to achieve high torque and stability.

- Bending Tool: Includes a set of specialized dies and rollers used to bend the pipe.

- Cooling and Safety Mechanisms: Ensure that the machine operates smoothly during extended use.

This automatic pipe-bending machine uses advanced software and hardware to automate the bending process, making it suitable for high-demand industries that require fast, reliable, and high-precision results.

Parameters of Full CNC Pipe Bending Machine

| Max. Bending Diameter for Carbon Steel | ф38mm |

| Max. Bending Radius | R200mm |

| Min. Bending Angle | 185° |

| Max. Effective Mandrel Length | 3150mm |

| Feeding Length | 2000mm |

| Feeding Speed | 1.17m/sec |

| Bending Accuracy | ±0.1° |

| Bending Speed | Max.171° / sec |

| Corner Accuracy | ±0.1° |

| Corner Speed | Max. 340° / sec |

| Power Supply | 380V, 50Hz |

| Control Valve Voltage | 24V |

| Servo Motor For Bending | 5KW |

| Servo Motor For Feeding | 1KW |

| Servo Motor For Rotating | 0.75KW |

| Motor For Oil Hydraulic | 4KW |

| Net Weight | 1500Kg |

| Dimension (L x W x H) | 4430mm x 1580mm x 1270mm |

| Control System | PLC |

Key Features of the Full CNC Pipe Bending Machine

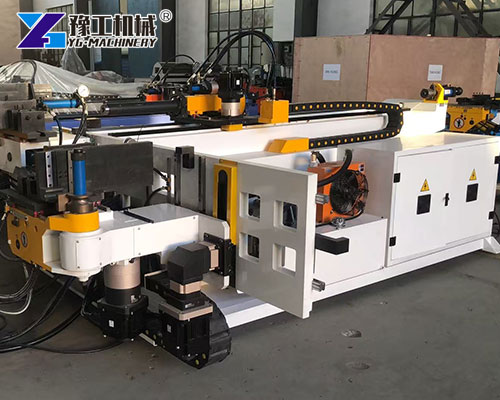

- High Precision Processing: The servo system ensures that the machine’s repeat positioning accuracy is up to ±0.05mm, with angle errors of less than ±0.1°. This makes it suitable for industries such as aerospace and automotive, where high precision is critical.

- Flexible Production: The machine supports complex 3D bending paths, including S-bends and spiral bends. This flexibility eliminates the need for frequent die changes, allowing for efficient production of different pipe fittings without major setup times.

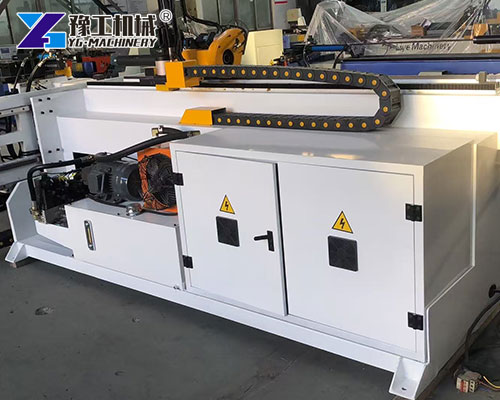

- High Efficiency and Stability: The hydraulic drive system provides the machine with high torque and short bending cycle times. The modular design and heat dissipation protection system ensure stable operation during long-term use.

- User-Friendly Operation and Maintenance: The machine comes with a touch screen that supports both “teach mode” and CAD drawing imports. The modular structure makes fault diagnosis and maintenance easier.

These features ensure that the CNC pipe bending machine delivers both high performance and flexibility, making it a valuable asset for manufacturers requiring precision and speed.

Applications of the Full CNC Pipe Bending Machine

This pipe-bending machine for metal pipes is used in various industries, including:

- Automotive Industry: For the production of pipes used in heat management systems, mufflers, and chassis brackets.

- Aerospace Industry: Precision bending of hydraulic pipes, engine components, and other complex pipe fittings.

- Construction and Decoration: Bending pipes for handrails, fences, and curtain wall supports.

- Energy and Machinery: Ideal for bending thick-walled pipes for petrochemical pipelines, as well as hydraulic systems used in machinery like excavators and cranes.

Given the continuous demand for high-quality pipes in these sectors, the automatic pipe-bending machine is a critical tool for ensuring efficient and precise production.

How Does the Full CNC Pipe Bending Machine Work?

The operation of a CNC pipe-bending machine involves a straightforward process:

- Jumbo Pipe Placement: The pipe is loaded into the machine.

- Perforation and Embossing: If required, the machine can apply embossing or perforations to the pipe surface.

- Bending: The pipe is bent into the required shape using CNC-controlled servo motors or hydraulic pressure.

- Cutting: After bending, the pipe is cut to the specified length.

- Packaging: The finished pipes are automatically packaged, if needed.

Automatic Pipe Bending Machine systems feature:

- PLC control for precise operation.

- Adjustable speeds to meet varying production needs.

- Energy-saving capabilities that help reduce operational costs.

Key Advantages of the Full CNC Pipe Bending Machine

- High-Volume Production: This machine is capable of producing high volumes of precisely bent pipes, making it ideal for large-scale manufacturers.

- Energy Efficiency: Advanced design features reduce waste and optimize power consumption, making it an eco-friendly option.

- Quality Assurance: The CNC pipe bending machine ensures consistent product quality with clean bends, minimal deformation, and accurate dimensions.

- Versatile: It can accommodate various pipe sizes, materials, and bending configurations, making it ideal for industries that need flexible and adaptive solutions.

How to Choose the Right CNC Pipe Bending Machine

When selecting a CNC pipe bender machine, consider the following factors:

- Pipe Diameter and Wall Thickness: Determine the size and material of pipes to be bent. For thicker pipes, choose a model with high torque hydraulic or servo-driven systems.

- Precision and Efficiency: For small-batch complex 3D parts, focus on machines that support CAD imports and offer servo control for better precision.

- Production Needs: If you need high-volume production, opt for fully automated lines with minimal manual intervention.

- Investment and ROI: Compare the cost of the machine with potential savings in labor and material waste, as well as the expected return on investment.

- After-Sales Service: Choose a manufacturer that offers comprehensive training, technical support, and long-term maintenance for continued productivity.

YG Machinery After-Sales Service

YG Machinery offers extensive after-sales services for our Full CNC Pipe Bending Machine, ensuring that your equipment stays in top working condition:

- 1-2 Year Warranty: Protection against manufacturing defects and malfunctions.

- Installation and Training: On-site or online training sessions for your operators to ensure smooth machine operation.

- Spare Parts Availability: Easy access to parts, with a supply chain ready to support long-term use.

- On-Site Maintenance Support: Engineers available to address any technical issues that may arise.

The Full CNC Pipe Bending Machine is an essential tool for industries that require precision, flexibility, and high throughput in pipe bending. With its advanced features, high efficiency, and energy-saving capabilities, it is a sound investment for manufacturers aiming to improve production quality and reduce costs.

👉 Contact YG Machinery today to receive a customized plan and the latest price for your Full CNC Pipe Bending Machine.

WhatsApp/WeChat/Phone: 86 138 3715 9132