What Is A High-Frequency Wall Saw?

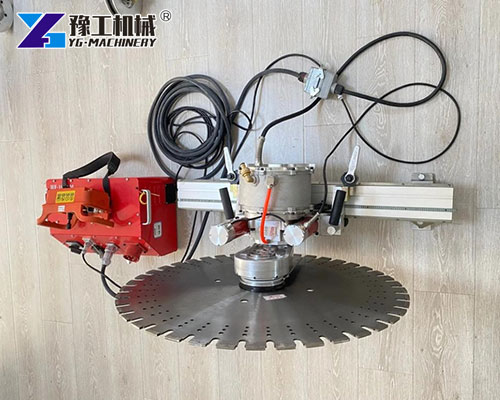

A high-frequency wall Saw is a professional machine used to cut concrete walls, floors, and other solid structures. Unlike older hydraulic saws, it uses a high-frequency electric motor for more stable and powerful cutting. Many people also call it an Electric Wall Saw because it runs on electricity and does not rely on oil pressure.

This saw is:

- Used for precise and clean cuts

- Mounted on a track that guides it along the wall

- Able to cut concrete, brick, and even reinforced steel

- Popular in building construction, bridges, and tunnel works

A high-frequency wall Saw makes cutting fast, clean, and safer for workers.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of High-Frequency Wall Saw

| Saw Blade | |

| Max. cutting depth | 510mm |

| Max. saw blade | φ1200mm |

| Saw blade fixing(flush cuts) | 6 countersunk head screws,110mm graduated circle. |

| Electric motor(water cooling & high frequency) | |

| Max. Output Power | 16kw |

| IP Classification | IP 67 |

| Weight | |

| Wall Saw 105DM Incl. Feed Electric Motor | 27kg |

| Electric Main Motor 16kw | 18kg |

| Control Unit | |

| Voltage | 380-460V(single phase available) |

| Frequency | 50Hz/60Hz |

| Weight | 19kg |

| Wireless Control | 2kg |

5 Key Advantages Of High-Frequency Wall Saw

The High Frequency Wall Saw offers many benefits that help save time and money on projects:

- High Cutting Efficiency

Cuts through thick concrete faster than traditional machines. - Lower Noise Levels

Runs quieter than hydraulic systems, reducing job site noise. - Lightweight And Compact

Easier to carry and install, especially in high places or tight areas. - Precise Cutting Control

Electric power allows smooth speed adjustments for perfect cuts. - Less Maintenance Needed

Fewer moving parts mean less chance of leaks or breakdowns.

These advantages make the High Frequency Wall Saw a smart choice for modern contractors.

Electric Wall Cutting Machine: How It Works

An Electric Wall Cutting Machine uses an electric motor to spin a diamond blade at very high speeds. It mounts on a metal track fixed to the wall for stable movement. Operators control the cutting depth and speed using a remote control.

Some highlights:

- Electric motors reduce vibration

- Water cooling keeps the blade from overheating

- Cuts up to 500 mm deep, depending on blade size

- Works well for both vertical and horizontal cuts

This makes an Electric Wall Cutting Machine perfect for large and small cutting jobs.

High Frequency Wall Saw Vs Traditional Wall Saw

Here’s how the High Frequency Wall Saw compares to a traditional hydraulic wall saw:

| Feature | High Frequency Wall Saw | Traditional Wall Saw |

|---|---|---|

| Cutting Speed | Faster (20-30% faster) | Slower |

| Noise Level (dB) | ~85 dB | ~100 dB |

| Maintenance Frequency | Low | Higher |

| Total Cost of Ownership | Lower over time | Higher due to oil leaks and repairs |

| Typical Applications | Precise jobs, tunnels, bridges | Standard demolition |

This table shows why many companies prefer the High Frequency Wall Saw for modern projects.

Real Case: Tunnel Cutting Project

One example of the High Frequency Wall Saw in action is from a tunnel project in the Philippines. The job required cutting ventilation shafts through 60 cm-thick concrete walls in a highway tunnel.

Challenges faced:

- Working in a tight space underground

- Keeping noise levels low

- Maintaining safety around traffic zones

The construction team used a YG High Frequency Wall Saw and finished cutting 30 meters of concrete walls in just four days.

Results achieved:

- Cutting speed improved by 25%

- Noise stayed under 85 dB

- Workers were safer due to the electric operation

The project manager said:

“The YG High Frequency Wall Saw made our tunnel work faster and safer. We will definitely use it again for future jobs.”

Choosing The Right Wall Cutter Machine

If you plan to buy a wall cutter machine, consider these points:

- Cutting Depth: Deeper cuts need bigger motors and stronger blades.

- Blade Size Compatibility: Check your saw supports different blade diameters.

- Weight and Size: Lightweight machines are easier for high-rise work.

- Noise Level: Electric saws are quieter than hydraulic ones.

- Power Source: Choose electric models if you work indoors or need less noise.

A good wall cutter machine should fit your job size and safety needs.

FAQs About High-Frequency Wall Saw

Q: Can a high-frequency wall Saw cut reinforced concrete?

A: Yes. Our saws cut concrete and steel bars inside walls.

Q: How deep can it cut?

A: Cutting depth ranges from 200 mm up to 800 mm.

Q: Does the machine make a lot of dust?

A: No. Water cooling reduces dust and keeps the workspace clean.

Q: Is it hard to maintain?

A: Not at all. Electric systems have fewer parts and need less service.

Contact YG Machinery today to get your custom quote for a High Frequency Wall Saw and improve your construction efficiency!

WhatsApp/WeChat/Phone: 86 138 3715 9132