The horizontal directional drill rig is a trenchless construction machine used to install underground utilities such as pipelines, cables, and conduits without digging trenches. Instead of open-cut excavation, it drills horizontally beneath the surface, reducing surface disruption and minimizing environmental impact. Whether for urban utility lines or crossing under roads and rivers, this equipment offers an efficient and non-invasive solution.

The horizontal directional drill rig is essential in modern construction and infrastructure, making underground work faster, safer, and more cost-effective.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Horizontal Directional Drilling Machine Parameter:

| Model | YG-160A | YG-180 | YG-280 | YG-320 | YG-320A |

| Engine rated power | 100KW | 97KW | 160KW | 140KW/160KW | 160KW |

| Push and pull | Cylinder | Motor | Motor | Cylinder | Motor |

| Maximum drag/feed force | 160/100KN | 180/180KN | 280/280KN | 320/320KN | 320/320KN |

| The maximum torque of the powerhead | 5000N.n | 6000N.n | 10000N.n | 12000N.n | 12000N.n |

| Powerhead speed | 0-180r/min | 0-140r/min | 0-120r/min | 0-140r/min | 0-140r/min |

| Moving speed of powerhead | 30m/min | 20m/min | 20m/min | 20m/min | 20m/min |

| Maximum reaming hole diameter | Φ600mm | Φ600mm | Φ750mm | Φ800mm | Φ800mm |

| Drill rod length (single) | 3m | 3m | 3m | 3m | 3m |

| Drill pipe diameter | Φ60mm | Φ60mm | Φ73mm | Φ73mm | Φ73mm |

| Drill pipe diameter | 10-23° | 10-22° | 10-23° | 10-20° | 10-20° |

| Maximum mudflow | 160L/min | 250L/min | 320L/min | 320L/min | 320L/min |

| Maximum mud pressure | 100bar | 80bar | 80bar | 80bar | 80bar |

| Overall quality | 6700kg | 8500kg | 12500kg | 11500kg | 11200kg |

| Dimension(length*width*height) | 5700*1820*2400mm | 6400*2270*2340mm | 7100*2260*2450mm | 7100*2250*2450mm | 7662*2162*2450mm |

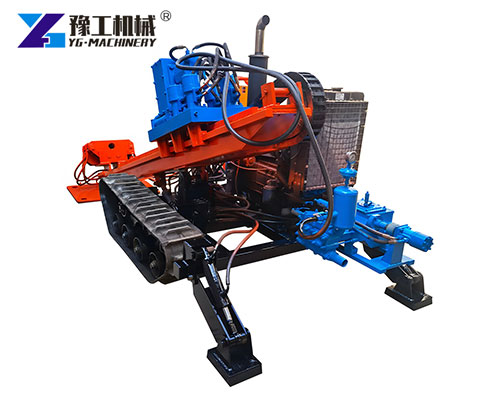

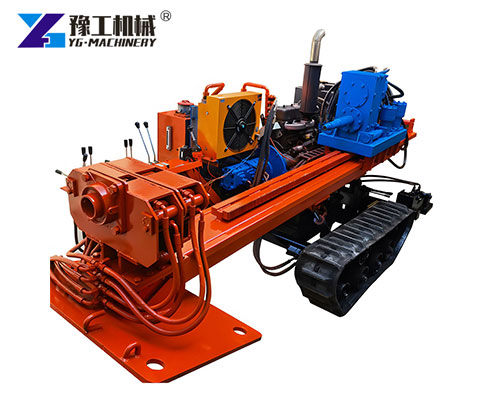

Components of an HDD Rig

An effective HDD rig relies on several essential components working in harmony to complete directional drilling operations smoothly:

- Drill Frame: The base structure that supports and aligns the drill pipe.

- Power Unit: Provides hydraulic or diesel power to drive the rotation and thrust systems.

- Control Station: Allows the operator to monitor and control drilling direction, speed, and pressure.

- Mud Pump System: Circulates drilling fluid (mud) to cool the drill bit and remove debris.

- Rod Loader or Pipe Rack: Feeds drill rods into the system for continuous boring.

- Tracking and Guidance System: Ensures accurate bore path with real-time data feedback.

How a Horizontal Directional Drilling Machine Works

The operation of a Horizontal Directional Drilling Machine involves a multi-stage process:

- Pilot Bore Drilling: You can use the steerable cutting – tool – fitted drill head to advance it into the ground at a shallow inclination. The operator can adjust the direction of the drill head using a combination of rotation and thrust, guided by a locating system that tracks the drill head’s position and depth.

- Steering: During the pilot bore, a surface tracking system or a downhole surveying tool continuously monitors the drill head’s position. This allows the operator to make necessary adjustments to the drilling path to avoid obstacles and follow the planned route.

- Reaming: Once you complete the pilot bore at the exit point, you replace the drill head with a reamer – a cutting tool with a larger diameter. Then, you pull the reamer back towards the rig, which enlarges the borehole to the size required for the product line. You may repeat this process using progressively larger reamers.

- Product Pullback: After you have reamed the borehole to the desired diameter, you attach the product pipe or cable to the drill string through a swivel. The Horizontal Directional Drilling Machine then pulls the product back through the enlarged borehole, completing the installation.

Key Applications of Horizontal Directional Drilling Equipment

- Telecommunications: Installation of fiber optic cables and conduits.

- Oil and Gas: Laying pipelines for the transportation of petroleum products.

- Water and Sewer: Installation of water mains and sewer lines.

- Electrical Power: Undergrounding power cables.

- Environmental Remediation: Installation of monitoring wells and remediation systems.

- River and Road Crossings: Installing utilities beneath natural and man-made obstacles.

Advantages of Using HDD Rigs

Using a horizontal directional drill rig offers multiple benefits over traditional trenching or open-cut methods:

- Minimal Surface Disruption: Preserves roads, landscaping, and structures.

- Reduced Environmental Impact: No need for large-scale excavation or surface restoration.

- Lower Labor Costs: Fewer workers are needed compared to trench-digging teams.

- Safer for Crowded Areas: Reduces hazards around traffic and pedestrian zones.

- Longer Installation Lengths: Can drill hundreds of meters in a single pass.

- Higher Accuracy: GPS and real-time tracking ensure precise placement.

These advantages translate into significant time and cost savings for contractors and municipalities.

Factors to Consider When Choosing an HDD Rig

Selecting the right Horizontal Directional Drill Rig for a project is crucial for efficiency and success. Several factors should be taken into account:

- Drilling Length and Diameter: The maximum distance and diameter the rig can handle.

- Thrust and Pullback Force: The power of the rig to advance the drill string and pull back the product.

- Ground Conditions: The type of soil and rock the rig is designed to drill through.

- Job Site Constraints: The size and accessibility of the work area.

- Portability and Transportation: The ease with which the rig can be moved between job sites.

- Operator Experience and Training: The complexity of the rig’s controls and the level of expertise required to operate it safely and effectively.

- Maintenance and Support: The availability of spare parts and technical assistance from the manufacturer.

Why Choose YG Machinery for Horizontal Directional Drill Rigs

YG Machinery offers reliable and efficient HDD solutions tailored to your drilling needs. When you choose YG:

- You get robust engineering built to withstand diverse working conditions.

- All rigs feature user-friendly controls for enhanced precision and productivity.

- Our rigs are known for low maintenance and long service life.

- We offer customized configurations for various pipe sizes, depths, and soil types.

- You benefit from fast delivery and responsive support, both pre- and post-sale.

YG Machinery combines quality, affordability, and field-proven reliability in every horizontal directional drill rig.

WhatsApp/WeChat/Phone: 86 138 3715 9132