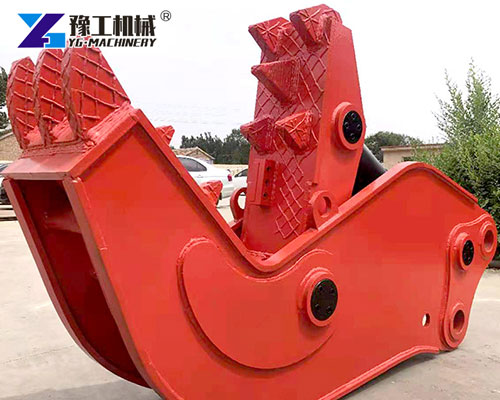

The Hydraulic Pulverizer is a high-efficiency excavator attachment used in demolition, recycling, and construction. Designed to crush concrete, cut rebar, and separate materials, it significantly reduces manual labor and boosts jobsite productivity. Whether you’re tearing down a building or processing waste concrete, a hydraulic pulverizer offers a safe, precise, and economical solution.

YG’s hydraulic concrete pulverizers are compatible with a wide range of excavators and are engineered for powerful crushing performance even under harsh conditions.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Hydraulic Pulverizer Attachment Parameters

| Model | YG-50 | YG-80 | YG-150 | YG-250 | YG-350 |

| Applicable Model(T) | 3-5 | 6-8 | 12-18 | 20-28 | 30-40 |

| Working Pressure(Mpa) | 24.5 | 24.5 | 31.5 | 31.5 | 31.5 |

| Overall Length | 950 | 1270 | 1620 | 1920 | 2130 |

| Overall Weight(KG) | 240 | 560 | 1150 | 1940 | 2790 |

| Maximum Opening(mm) | 430 | 600 | 745 | 880 | 1030 |

| Blade Length(mm) | 70 | 100 | 120 | 160 | 180 |

| Front Breaking Force(KN) | 178 | 382 | 549 | 725 | 1080 |

| Central Crushing Force(KN) | 282 | 598 | 882 | 1170 | 1750 |

Key Features Of The Hydraulic Pulverizer

- High crushing force through advanced hydraulic cylinders

- Replaceable wear-resistant teeth for extended service life

- 360° rotating model available for flexible positioning

- Reinforced jaws that handle concrete and rebar easily

- Compact and rugged structure suitable for tight working environments

- Low noise and low vibration, reducing environmental impact

Applications of Hydraulic Excavator Pulverizers

YG Hydraulic Excavator Pulverizers are versatile attachments with a wide range of applications in the demolition and recycling industries:

- Primary Demolition: Efficiently crushing and reducing the size of concrete structures, walls, columns, and slabs.

- Secondary Crushing and Material Separation: Further breaking down demolished concrete into smaller pieces for easier handling and separation of steel reinforcement.

- Concrete Recycling: Preparing concrete debris for crushing and recycling into aggregate for new construction projects.

- Bridge and Infrastructure Demolition: Controlled demolition and material processing of concrete bridges, overpasses, and other infrastructure elements.

- Industrial Plant Dismantling: Efficiently breaking down concrete foundations and structures during the dismantling of industrial facilities.

- Disaster Recovery: Assisting in the clearing and processing of debris in disaster-stricken areas.

Working Principle Of A Hydraulic Pulverizer

The concrete pulverizer uses the excavator’s hydraulic system to deliver high-pressure force through its jaws, crushing material with precision. Its operation is based on a simple, efficient principle:

- The pulverizer is mounted onto the excavator’s boom or stick.

- Hydraulic pressure is supplied through the excavator’s system.

- When activated, the jaws close with intense force, crushing concrete and cutting rebar.

- The rotating models allow precise alignment with the material without repositioning the excavator.

- Crushed material falls away, ready for further processing or disposal.

Why choose a Concrete Pulverizer for Excavator

The Concrete Pulverizer for Excavator is a must-have for any contractor dealing with concrete demolition. It simplifies complex tasks and delivers consistent performance with each use.

Easy integration with most excavator brands

Saves time during large-scale demolition projects

Ideal for selective demolition in urban areas

Capable of handling steel-reinforced concrete

Enables quick separation of recyclable materials

Thanks to its rugged design and strong grip, the pulverizer increases excavator utility and project profitability.

Other Excavator Attachments

In addition to the hydraulic pulverizer, YGMachinery offers a variety of powerful excavator attachments tailored to different tasks: Vibratory Pile Driver, Hydraulic Pile Crusher, Double Cylinder Hydraulic Shear, Hydraulic Pile Driver, Hydraulic Breaker, Hydraulic Drum Cutter, Hydraulic Rock Saw, and Orange Peel Grapple. Each tool is engineered to improve excavator efficiency and adapt to dynamic jobsite demands.

WhatsApp/WeChat/Phone: 86 138 3715 9132