A Hydraulic Stone Splitter is a machine used to break large rocks, stones, or concrete without using explosives. It works by inserting a wedge into a drilled hole and applying strong hydraulic force to split the material. This method is safer, quieter, and more controlled than traditional blasting.

It is often used in quarries, mining areas, or city demolition projects where noise and vibration must be reduced.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Technical Parameters of Hydraulic Stone Splitter

| Model | YG-250 | YG-350 | YG-450 |

| Power | Diesel Power Pack | ||

| Diesel Power Pack | Changchai 6hp or 8hp | ||

| Hydraulic Power Unit | Pressure Adjustable 10- 60MPa | ||

| Splitter Length (mm) | 1000 | 1100 | 1200 |

| Wedge Length (mm) | 250 | 350 | 450 |

| Wedge Weight (kg) | 30 | 36 | 43 |

| Piston Stroke (mm) | 90/220 | 90/220 | 90/220 |

| Drilling Depth (mm) | >500 | >700 | >900 |

| Drilling Diameter (mm) | 42 | 50 | 55 |

| Crack Width (mm) | 10-20 | 10-20 | 10-20 |

| Splitting Time (s) | 10-15 | 10-15 | 10-15 |

| Splitting Force (T) | 800 | 900 | 1000 |

Components Of A Hydraulic Rock Splitter System

The Hydraulic Stone Splitter is used together with a rock drilling machine. It cannot work alone. The complete system usually includes:

- Drilling Machine: Makes holes in rock or concrete.

- Splitter Cylinder: The main splitting tool, inserted into the hole.

- Hydraulic Pump Station: Powers the splitter with high-pressure oil.

- Hoses and Connectors: Transfers power from the pump to the splitter.

The splitter head is made of high-strength alloy steel to resist wear and breakage. One power station can control multiple splitter heads.

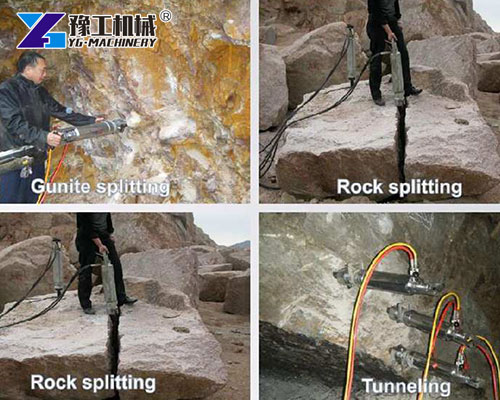

Hydraulic Rock Splitter Applications

Hydraulic Rock Splitter systems are widely used in the following areas:

- Quarry Operations: Splitting granite, marble, and other hard stone into blocks.

- Boulder Breaking: Breaking large rocks in road construction or site leveling.

- Mining Projects: Opening tunnels or extracting ore in low-noise areas.

- Building Demolition: Controlled breaking of reinforced concrete without flying debris.

- City Excavation: Used in subway or foundation work where blasting is not allowed.

Advantages Of Using A Rock Splitting Machine

Compared to traditional explosives or hammers, a Rock Splitting Machine offers many benefits:

- No Dust, No Noise: Safe for use in city or enclosed spaces.

- Accurate Control: Splits only where you want it.

- Low Cost: Lower maintenance and labor costs than other methods.

- Reusable Tools: The splitter head lasts for thousands of uses.

- Simple Operation: No license or special training required.

These advantages make it ideal for both small contractors and large mining companies.

Other Stone Splitting Solutions

YG Machinery also offers alternative tools for different rock-breaking needs:

- Hydraulic Splitting Rods: Long rods inserted into deep holes for splitting thick rocks.

- DTH Drilling Rigs: For drilling deep, precise holes before splitting.

- Integrated Drilling and Splitting Machines: Save time by combining two functions in one unit.

Each tool suits different project sizes and rock conditions. Contact YG to match the best tool to your job.

Factors That Affect Hydraulic Rock Splitter For Mining Use

For a hydraulic rock splitter for mining, there are a few key points to consider before choosing the right equipment:

- Rock Hardness: Granite, limestone, and basalt require different pressures.

- Hole Size and Depth: Match the splitter cylinder length to the drilled hole.

- Site Conditions: Temperature, altitude, and humidity may affect oil pressure.

- Job Size: Small jobs need one splitter; large mines may need 3–6 heads.

- Budget: Splitter systems are cost-effective, but different models vary in price.

YG sales engineers can help recommend the right setup based on your project.

YG Machinery After-Sales Support

When you buy a Hydraulic Stone Splitter from YG Machinery, you get more than just the machine:

Technical Training: We offer video instruction or remote guidance.

Spare Parts Supply: Pistons, hoses, and oil pumps are available at any time.

Global Delivery: Fast shipping to Europe, South America, Southeast Asia, and more.

Warranty Service: 12-month warranty for core parts.

For larger buyers, YG can offer on-site training and custom packaging based on your country’s safety rules.

WhatsApp/WeChat/Phone: 86 138 3715 9132