The hydraulic thread rolling machine is an industrial tool used to create precise threads on metal workpieces through cold forming. Unlike cutting, thread rolling uses pressure to form threads, increasing strength and material integrity. YG Machinery manufactures high-quality machines that are ideal for mass production, ensuring smooth operation and accurate thread profiles with minimal wear.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Hydraulic Thread Rolling Machine Parameter

| Model | YG28-40 | YG28-80 | YG28-150 | YG28-185 | YG28-200 |

| Max rolling pressure | 120KN | 150kn | 150kn | 180kn | 200kn |

| Hydraulic diameter | 5-36MM | 6-42mm | 6-48 | 10-60mm | 14-80mm |

| Rolling wheel diameter | 120-170MM | 120-170mm | 120-170mm | 175-220mm | 175-220mm |

| Max width of rolling wheel | 110MM | 110MM | 110MM | 150mm | 150mm |

| Spindle center distance | 120MM | 120MM | 120MM | 150-300mm | 150-300mm |

| Rolling wheel aperture | 54hole | 54hole | 54hole | 75hole | 75hole |

| Hydraulic power | 4kw | 2.2kw | 2.2kw | 3kw | 5.5kw |

| Main motivation | 4kw | 5.5kw | 7.5kw | 11kw | 11kw |

| Spindle speed | 36-78/min | 36-78/min | 36-78/min | 20-64/min | 20-64/min |

| Spindle tilt angle | ±5° | ±5° | ±5° | ±10° | ±10° |

| Thread length | No limited | No limited | No limited | No limited | No limited |

| Dimensions | 1.4*1.2*1.4m | 1.48*1.33*1.44m | 1.47*1.33*1.44m | 1.78*1.73*1.43m | 1.78*1.73*1.43m |

| Weight | 1100kg | 1700kg | 1800kg | 2000kg | 2600kg |

Thread Rolling Machine Types For Different Needs

YG offers various types of thread rolling machine models to suit different applications and industries:

- Two-Die Thread Rolling Machine: The most common model, suitable for threading bolts, studs, and shafts.

- Three-Roll Thread Rolling Machine: Ideal for larger diameter materials, ensuring uniform pressure from all directions.

- Flat Die Thread Rolling Machine: Often used for threading small parts at high speed.

- Hydraulic Thread Rolling Machine: Uses hydraulic force for consistent thread depth and minimal deviation.

- CNC Thread Rolling Machine: Offers full automation and programmable operations for precision production.

Each model serves a specific purpose and is designed to improve production efficiency and output quality.

Key Features Of Hydraulic Thread Rolling Machine

The hydraulic thread rolling machine from YG comes with several core features that enhance its reliability and performance:

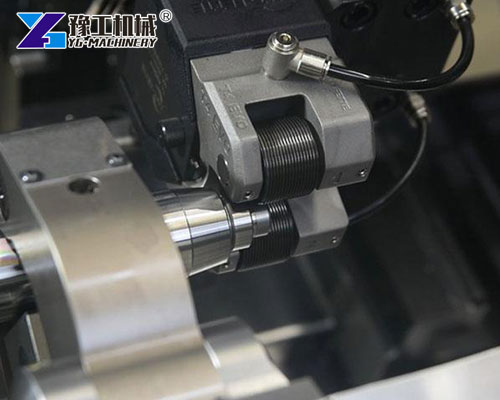

- Hydraulic Power System: Provides stable and adjustable pressure for consistent threading results.

- Heavy-Duty Frame: Reduces vibrations and extends the life of components.

- Precision Dies: Made of heat-treated alloy steel for long service life.

- Wide Compatibility: Suitable for threading steel, aluminum, copper, and alloy rods.

- Simple Controls: Intuitive interface makes operation easy, even for beginners.

Working Principle Of Hydraulic Thread Rolling Machine

The machine uses hydraulic cylinders to apply force on two or more dies that are pressed against a rotating metal part. The friction and pressure deform the material into the desired thread shape without removing any material. This process offers several advantages:

- Stronger threads due to cold working

- Faster processing times

- Minimal material waste

- No chips or burrs created

Hydraulic control ensures constant pressure, making it possible to roll threads accurately and repeatedly, even on large-volume production lines.

Applications of Hydraulic Thread Rolling Machines

The exceptional strength, precision, and efficiency offered by a hydraulic thread rolling machine make it an indispensable tool across a vast array of industries. Its ability to produce high-quality threads on various materials ensures its broad applicability.

- Consumer Goods: Production of threaded parts for household appliances, furniture, and electronic devices, ensuring durability and ease of assembly.

- Automotive Industry: Widely used for manufacturing a multitude of threaded components such as bolts, studs, engine parts, axle shafts, and steering components, where high strength and fatigue resistance are critical for safety and performance.

- Aerospace Industry: For fasteners and structural components in aircraft, which demand the highest levels of precision, strength, and reliability. The enhanced fatigue life of rolled threads is particularly beneficial here.

- Construction and Infrastructure: Production of anchor bolts, rebar couplers, tension rods, and heavy-duty fasteners used in bridges, buildings, and other large-scale construction projects.

- Heavy Machinery: Manufacturers produce threaded shafts, bolts, and connecting rods for agricultural equipment, mining machinery, and industrial robots, where these components withstand extreme loads.

- Fastener Manufacturing: The backbone of the commercial fastener industry, producing millions of screws, bolts, nuts, and rivets for general industrial and consumer use.

- Medical Devices: For precision threads on surgical instruments, prosthetics, and implants, where exact dimensions and high surface finish are vital for functionality and biocompatibility.

- Oil and Gas Industry: Used for threading pipes, couplings, and specialized downhole tools that operate in harsh environments under high pressure and temperature.

Related Equipment Offered By YG Machinery

In addition to the hydraulic thread rolling machine, YG provides a wide range of related machinery:

- Rebar Threading Machine: Ideal for construction and infrastructure projects.

- Bolt Making Machine: For complete bolt production, including heading and threading.

- Pipe Threading Machine: Specially designed for threading water, gas, or oil pipes.

- Hydraulic Cutting Machines: For precise cutting of metal rods and pipes.

All products are built for high durability and operational efficiency.

YG Machinery – Your Trusted Thread Rolling Machine Manufacturer

As a leading manufacturer, YG Machinery produces high-performance thread rolling machines with competitive pricing and provides outstanding after-sales support. We design our machines to meet global standards, and clients in the automotive, construction, and machinery sectors trust them.

WhatsApp/WeChat/Phone: 86 138 3715 9132