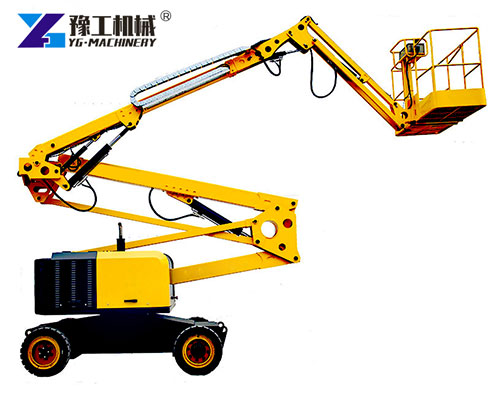

What Is a Knuckle Boom Lift?

A Knuckle Boom Lift is a type of aerial work platform with multiple arm sections connected by joints. These joints allow the lift to bend or “knuckle,” helping it move around obstacles and reach tight spaces. Also known as an Articulating Boom Lift, it offers more flexibility than straight boom lifts.

This machine is commonly used to lift workers and tools to elevated positions for tasks like construction, tree trimming, maintenance, and warehouse operations.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Knuckle Boom Lift Parameter

| Type number | YG-8 | YG-10 | YG-12 | YG-14 |

| External dimension (mm) | 4000*1700*2700 | 4000*1700*2700 | 4800*2100*3050 | 5100*2200*3300 |

| Platform height (m) | 8 | 10.5 | 12 | 13.5 |

| Load (kg) | 180 | 180 | 180 | 180 |

| Operation radius (m) | 3 | 3.4 | 4 | 4.2 |

| Self-weight (Kg) | 1500 | 1600 | 1800 | 1900 |

| Walking speed (km/h) | 15-30 | 15-30 | 15-30 | 15-30 |

How a Knuckle Boom Lift Works

The knuckle boom lift uses a hydraulic system to extend and bend its arms. It has a platform or bucket at the end, where workers can stand safely. The base unit stays on the ground while the boom extends upward and outward.

Key working elements include:

- Hydraulic cylinders for arm movement

- Electric or diesel motor for power

- Joystick controls for easy operation

- Safety sensors and emergency shut-offs

The machine can move vertically and horizontally, making it ideal for complex job sites.

Main Features of a Knuckle Boom Cherry Picker

- Flexible Reach: Its articulating arm can bypass obstacles and reach even the most hard-to-access places.

- Compact Design: Can be used in narrow or tight areas.

- High Lifting Height: Suitable for tasks requiring elevation up to 30 meters or more.

- Easy Operation: Simple control panel, even for new users.

- Stable Platform: Offers safety and comfort for workers at height.

How to Operate a Knuckle Boom Lift

Operators must be trained before using a knuckle boom lift. Here’s how it typically works:

- Park the lift on level ground.

- Perform a safety inspection.

- Turn on the power system (electric or diesel).

- Use the control panel to move the boom.

- Navigate the boom slowly to the desired position.

- Keep communication with the ground staff.

Always follow local safety guidelines and wear a harness if needed.

Top Applications of Knuckle Boom Lift for sale in Construction

In construction sites, Knuckle Boom Lifts are widely used for:

- Installing glass panels on tall buildings

- Painting or finishing walls

- Electrical and piping works at heights

- Roofing and cladding

They save time and labor costs, especially on projects with limited space or uneven ground.

Why Use a Knuckle Boom Cherry Picker for Tree Trimming?

A Knuckle Boom Cherry Picker is perfect for landscape and garden maintenance.

Advantages include:

- Accessing tall or spread-out branches easily

- Avoiding obstacles like fences or walls

- Providing a safe platform for trimming

- Reducing the need for climbing or ladders

Its jointed arms help reach over hedges or structures without moving the base unit often.

Knuckle Boom Lifts in Warehouse and Logistics Operations

In large warehouses, a Knuckle Boom Lift for sale is a valuable tool for:

- Inventory checking at high shelves

- Installing or maintaining lighting systems

- Cleaning ceilings or overhead structures

- Repairing HVAC ducts

Its small footprint and tight turning radius allow use between storage racks and narrow aisles.

Knuckle Boom Lifts for Telecommunication and Power Line Maintenance

For utility companies, Cherry Picker Boom Lifts are a smart choice. They help with:

- Repairing overhead telecom cables

- Installing 5G antennas on rooftops

- Maintaining power poles and transformers

- Performing emergency services in storms

Their height, flexibility, and safety features ensure smooth and quick operations.

What to Consider Before Buying a Knuckle Boom Cherry Picker for Sale?

When choosing a Knuckle Boom Cherry Picker, consider:

- Maximum Working Height: Match the lift to your project’s needs.

- Horizontal Reach: Important for accessing spaces over obstacles.

- Platform Capacity: Usually ranges from 200–300 kg.

- Power Source: Diesel, electric, or hybrid, based on worksite conditions.

- Indoor vs Outdoor Use: Choose tire type and emission levels accordingly.

- Transport Size: Check the overall dimensions for easy transport.

How to Choose the Right Knuckle Boom Lift for Your Project?

Every job has different needs. Choose the right lift by asking:

- Is your worksite indoor or outdoor?

- How high and how far do you need to reach?

- Do you need electric power for quiet operation?

- How many workers and tools will be on the platform?

Compare models based on specifications and consult with experts if unsure.

Safety Tips for Operating a Knuckle Boom Lift

To avoid accidents, follow these safety tips:

- Always inspect the lift before use

- Never exceed weight limits

- Wear protective gear, including a harness

- Keep the platform clean and dry

- Use outriggers if available

- Avoid power lines and stormy weather

Proper training is essential for safe operation.

Common Maintenance Practices for Knuckle Boom Cherry Pickers

Regular maintenance keeps the lift safe and functional. Key tasks include:

- Check hydraulic oil levels weekly

- Inspect arm joints and pivot points

- Lubricate moving parts

- Test emergency controls

- Replace worn tires or tracks

- Clean battery terminals (for electric models)

Always follow the manufacturer’s maintenance schedule.

Reliable After-Sales Service from YG Machinery

At YG Machinery, we provide more than just equipment. Our after-sales service includes:

- Free technical support

- Spare parts supply

- Online training for operators

- Fast delivery of replacement parts

- 12-month product warranty

Our team is ready to support your project anytime, anywhere.

WhatsApp/WeChat/Phone: 86 138 3715 9132