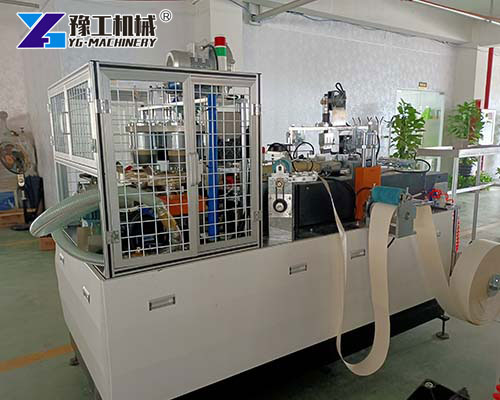

The paper bowl making machine is an industrial-grade device designed specifically to manufacture paper bowls. Its main job is to take raw paper materials, like PE-coated paper, and transform them into functional and aesthetically pleasing bowls. It automates a series of complex processes such as paper feeding, forming, cutting, sealing, and sometimes even printing, making the production of paper bowls efficient and consistent. WhatsApp/WeChat/Phone +86 138 3715 9132

Fully Automatic Paper Bowl Machine Parameter

| Model | Fully automatic paper bowl-forming machine |

| Bowl size | 20-50oz (It can be replaced according to the actual size of the user) |

| Raw material | single/double PE-coated paper |

| Paperweight | 140-350 g/m2 PE-coated paper |

| Machine speed | 110-130 pcs/min |

| Voltage | 380V 50Hz |

| Power | 4.8KW |

| Weight | 1980KG |

| Overall dimension | 2350 x1250 x1900mm |

| Air source | 0.6Mpa, 0.6 m3/minute |

| Remark | Machine production needs to be equipped with an air compressor |

How Does a Paper Bowl Making Machine Work?

- Material Feeding: The machine starts by feeding rolled paper or cardboard into the system. This material is typically pre-printed or plain, depending on the manufacturer’s requirements.

- Molding and Shaping: Using specialized dies and molds, the paper is shaped into the desired bowl form. For example, a Paper Bowl Forming Machine component ensures consistent bowl dimensions, from small snack bowls to large soup containers.

- Sealing and Trimming: The edges of the bowl are sealed to ensure durability, while excess material is trimmed away. This step is often automated in YG’s Automatic Paper Bowl Machine, reducing waste and improving efficiency.

- Quality Control: Built-in sensors check for defects, such as uneven edges or weak seals, to maintain product consistency.

Advantages of YG’s Paper Bowl Making Machine

- Eco-Friendly Production: Our Eco-Friendly Bowl Making Machine is designed to use recycled paper materials, aligning with global sustainability goals. It minimizes plastic waste and supports circular economy initiatives.

- High Efficiency: The Automatic Paper Bowl Machine can produce hundreds of bowls per minute, significantly reducing labor costs and increasing output. This is ideal for businesses facing high demand.

- Versatility: The machine can create various bowl sizes and designs, from disposable dessert bowls to sturdy ramen containers. This flexibility allows manufacturers to cater to diverse customer needs.

- Durability and Reliability: Built with high-quality steel and advanced components, YG machines are designed for long-term use, ensuring minimal downtime and maintenance costs.

Factors to Consider When Choosing a Disposable Bowl Forming Machine

- Production Capacity: Determine whether you need a small-scale Disposable Bowl Making Machine for artisanal products or a high-speed automatic model for mass production.

- Material Compatibility: Ensure the machine can handle different paper types, such as virgin pulp, recycled paper, or coated materials for waterproofing.

- Energy Efficiency: Look for machines with low power consumption to reduce operational costs. YG’s models are designed to be energy-saving without compromising performance.

- Ease of Operation: User-friendly interfaces and intuitive controls, like those in YG’s machines, simplify training for operators and reduce the risk of errors.

- After-Sales Support: Choose a manufacturer that offers reliable maintenance, technical support, and spare parts availability.

Applications of Paper Bowl Machines

- Food and Beverage: Ideal for producing disposable bowls for soups, noodles, ice cream, and takeout meals.

- Events and Catering: Perfect for creating custom-printed bowls for weddings, corporate events, or festivals.

- Retail and Packaging: Used to make eco-friendly packaging for snacks, dry goods, and promotional products.

- Industrial Use: Suitable for producing specialized bowls for medical or industrial applications, such as wax melting bowls or laboratory containers.

Operational Guide for YG’s Paper Bowl Machine

- Pre-Operation Checks: Before starting, inspect the machine’s components, such as the mold alignment and conveyor belts, to ensure they are clean and functioning properly.

- Material Preparation: Operators should correctly load the paper rolls and align them with the feeding mechanism. Adjust the tension settings based on the material thickness.

- Parameter Setting: Program the machine to the desired bowl size, shape, and production speed. Use the touchscreen interface to save frequently used settings for quick recall.

- Regular Maintenance: Clean the machine after each use to remove paper scraps and debris. Schedule monthly inspections of the motor, gears, and electrical systems to prevent wear and tear.

Why Choose YG as Your Paper Bowl Making Machine Manufacturer?

YG has established itself as a trusted name in the industry for several reasons:

- Innovation: We continuously invest in research and development to improve our machines’ efficiency and sustainability. Our Eco-Friendly Bowl Making Machine is a testament to our commitment to green technology.

- Customization: We offer tailored solutions to meet specific production needs, whether you require a Disposable Bowl Making Machine with unique design features or a high-capacity Automatic Paper Bowl Machine.

- Global Expertise: With years of experience serving clients worldwide, we understand the diverse regulatory and market demands in Europe and America, ensuring our machines meet local standards.

- Customer Support: Our dedicated team provides end-to-end support, from installation and training to ongoing maintenance, ensuring your production process runs smoothly.

WhatsApp/WeChat/Phone +86 138 3715 9132