What Is a Paper Cup Production Line?

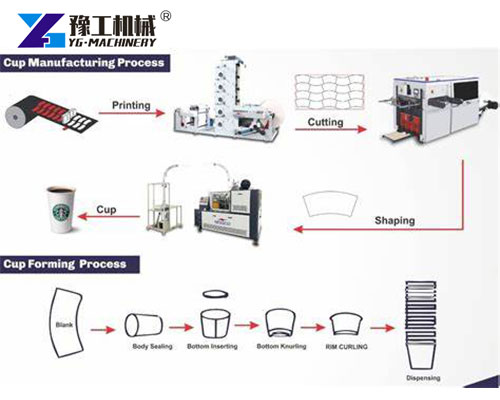

A paper cup production line is a full system to make paper cups from start to finish. It includes many machines. First, it cuts the paper. Then it makes the cup shape. After that, it packs the cups. This line helps factories make many cups quickly.

This line is different from a single disposable cup-making machine. A single machine can only form cups. A full production line does everything—cutting, forming, checking, and packing. It is great for big factories and mass production.

WhatsApp/WeChat/Phone: 86 138 3715 9132

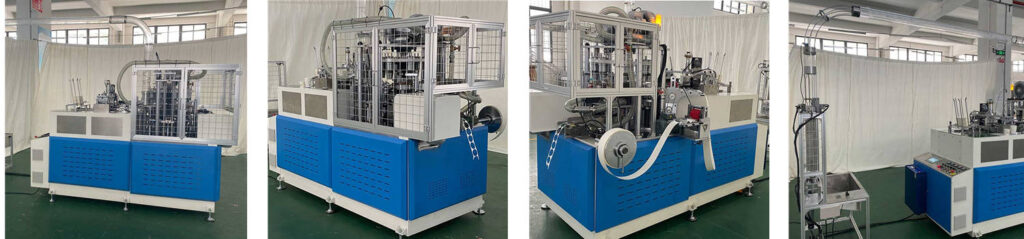

Parameters of the Automatic Paper Cup Machine:

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | ||||

Main Equipment in the Production Line

A full paper cup line usually has these machines:

- Paper Cutting Machine: Cuts large paper rolls into cup fan shapes.

- Flexo Printing Machine: Prints logos and colors on the paper.

- Paper Cup Forming Machine: Turns flat paper into a cup.

- Leak Tester: Checks if the cup leaks water.

- Cup Counting and Packing Machine: Stacks and packs finished cups.

Each machine works with the next one. They all run together in one line. This makes production smooth and fast.

Benefits of Using a Full Production Line

Using a paper cup production line gives many benefits:

- High Output: Can make thousands of cups per hour.

- Less Labor: Machines do most of the work.

- Better Quality: Less human error.

- Fast Return on Investment: Higher productivity means faster profits.

- Clean and Safe: No hand-touch during cup forming or packing.

Factories can save money and produce more cups with fewer people.

Ideal For Medium And Large Factories

This type of line is best for:

- Paper cup factories with big orders

- Food packaging companies

- OEM drink cup suppliers

- Manufacturers of disposable cups for restaurants, schools, and offices

Many large brands use this system to keep up with high demand.

Paper Types and Cup Sizes Supported

The production line can work with many kinds of paper:

- Single PE-Coated Paper

- Double PE-Coated Paper

- Printed Logo Paper Rolls

- Biodegradable Paper

The system supports cups from 4oz to 32oz. You can use the same line for small tea cups or large smoothie cups.

Options for Customization

You can add more features to the line:

- Double Wall Sleeve Machine for making insulated cups

- Embossing Machine for texture

- Bottom Pre-Heating System for thick paper

- Auto Paper Roll Loader for faster feeding

- Online Cup Counting System

This makes the production line fit your special needs.

How to Install and Operate

Installing a paper cup production line takes about 7–10 days. Most parts are already connected. Technicians will help test and run the machine.

Daily operation is simple:

- Turn on the system from the control panel

- Feed paper rolls into the first unit

- Check the glue and heating units

- Collect finished cups at the end

- Monitor the screen for any errors

Two to three people can manage the whole line.

Maintenance Tips for Long Use

To keep the line in good shape:

- Clean every part at the end of the day

- Use the right paper size and thickness

- Check heating and gluing parts weekly

- Lubricate moving parts regularly

- Remove paper dust to avoid jamming

With proper care, the machines can run for many years.

FAQ – Paper Cup Production Line

Q1: How many cups can the line make per hour?

It depends on the model. A full line can make 10,000 to 15,000 cups per hour.

Q2: Can I make both hot and cold drink cups?

Yes. The line supports both single and double PE paper.

Q3: Do I need to hire engineers?

No. Our team trains your staff during setup.

Q4: How much space is needed for the line?

Most lines need about 60–80 square meters.

Q5: Can I add other equipment later?

Yes. You can add packing or printing machines later as needed.

WhatsApp/WeChat/Phone: 86 138 3715 9132