The Paper Roll Slitting Machine is essential equipment in the paper converting industry. YG designs the equipment to cut large paper rolls into narrower widths, meeting precise application requirements. YG Machinery offers industrial-grade slitting machines that improve production efficiency and deliver clean, precise slits. Whether you’re processing kraft paper, coated paper, or thermal paper, our machines ensure consistent results.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Paper Roll Slitting Machine Parameter

| Model | YG- 1300 | YG- 1600 | YG- 1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Min width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

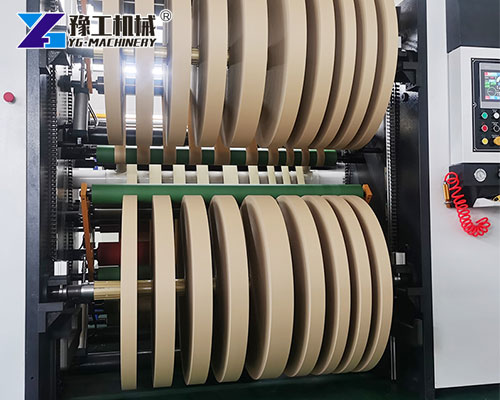

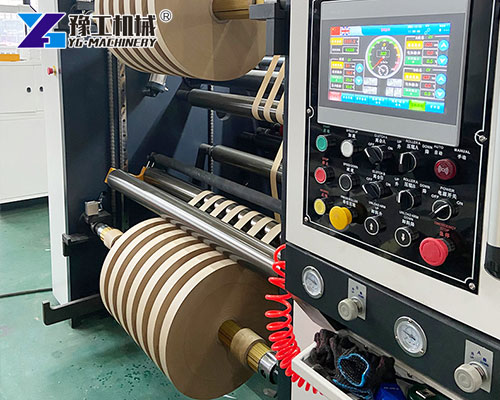

Features Of Paper Roll Slitting Machine

YG’s Paper Roll Slitting Machine is built to handle high-volume paper slitting tasks with speed and accuracy. Some of the key features include:

- Heavy-Duty Steel Frame: Ensures stability and reduces vibration during high-speed operation.

- Precision Circular Blades: Clean and smooth cutting with minimal edge burrs.

- Automatic Tension Control: Maintains consistent paper tension across the roll.

- User-Friendly Control Panel: Easy to set slit widths, speed, and unwind tension.

- Fast Roll Change System: Speeds up setup time, enhancing productivity.

These features make it ideal for long shifts and demanding slitting tasks.

Working Principle Of The Slitting Machine

The Paper Roll Slitting Machine operates on a simple yet effective principle:

- Unwinding Section: The master paper roll is loaded and unwound under controlled tension.

- Slitting Section: Rotary or razor blades slit the paper into desired widths as it passes through.

- Rewinding Section: The slit paper strips are rewound onto individual cores for packaging or further processing.

By maintaining precise alignment and tension, the machine ensures accurate slits even at high speeds.

Applications of Paper Roll Slitting Machines

Industries widely use the Paper Roll Slitting Machine for its flexibility and efficiency. Common applications include:

- Printing & Publishing: For preparing rolls used in offset and flexo printing.

- Packaging Industry: Producing narrow rolls for labels, bags, or carton liners.

- Thermal Paper Production: Slitting jumbo rolls for POS terminals and ATMs.

- Stationery Manufacturing: Preparing paper for notebooks, pads, and diaries.

Its ability to handle different paper grades and thicknesses makes it a valuable investment.

Paper Slitting Equipment With Smart Controls

YG equips today’s paper slitting equipment with smart automation features to reduce operator workload and improve consistency. These features include:

- Touchscreen HMI for intuitive setup

- Automatic blade positioning system

- Error detection and fault alerts

- Variable frequency drive (VFD) motor for precise speed control

Paper slitting equipment integrated with these smart systems helps businesses minimize waste and increase output quality.

Slitting Machine Manufacturer: YG Machinery

YG Machinery is a trusted manufacturer of slitting and converting equipment. Here’s what makes us stand out:

- Industry Experience: Over 20 years of manufacturing expertise.

- Global Support: Machines exported to 30+ countries with responsive after-sales service.

- Customization Available: Machines can be tailored to different paper types and sizes.

- Quick Delivery: Standard machines ready to ship, custom models in short lead time.

We serve both small startups and large-scale paper processing plants with the same dedication to quality and reliability.

WhatsApp/WeChat/Phone: 86 138 3715 9132