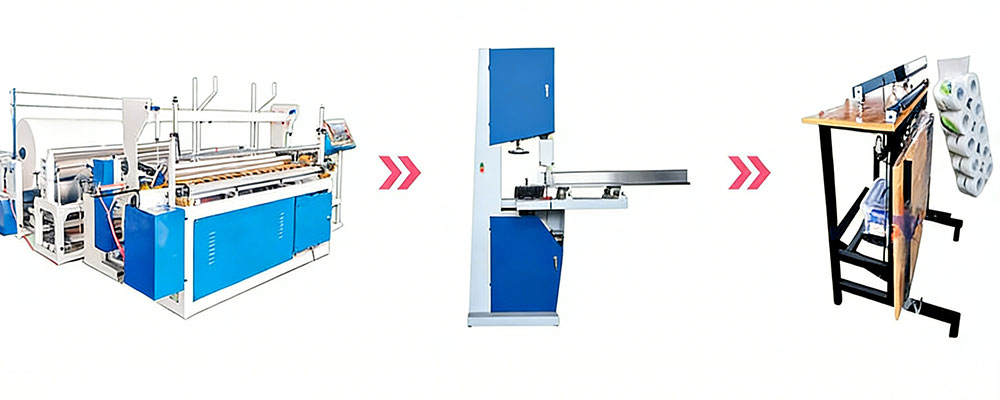

A Semi-Automatic Toilet Paper Machine is used to rewind jumbo tissue rolls into small rolls for daily use. The complete production line normally includes three machines: a toilet paper rewinding machine, a bandsaw cutting machine, and a packing machine. This setup offers low investment and simple operation, which makes it the perfect start for new manufacturers. We supply three main models: YG1575, YG1880, and YG3000. Many global buyers choose this machine because a semi-automatic design offers economic and efficient production while keeping labor needs low.

What Is A Semi-Automatic Toilet Paper Machine?

A Semi-Automatic Toilet Paper Machine rewinds large rolls into smaller rolls that keep the same width and sheet style.

It helps users enter the tissue business with less risk.

This production line is popular because:

- Lower startup cost compared with full-automatic machines

- Simple operation, easy for new workers to learn

- Small footprint, friendly for factories with limited space

- Flexible output, suitable for different roll sizes

- Fast return on investment, thanks to steady demand for toilet paper

Semi-automatic design offers the best balance between cost and efficiency, making it ideal for small and medium production lines.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Toilet Paper Rewinding Machine — Part Of The Toilet Paper Making Machine

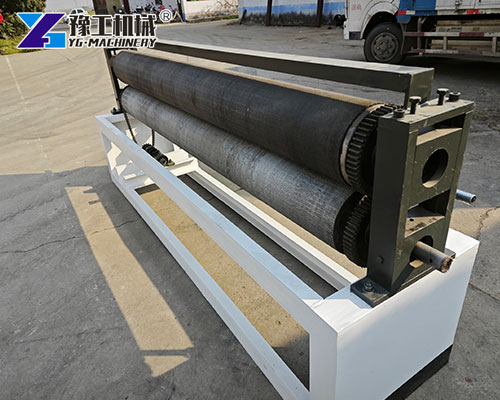

This toilet paper rewinding machine rewinds jumbo rolls into smaller rolls while keeping the same width.

It includes:

- Embossing unit

- Perforation unit

- 1–3 unwinding stands

- Electrical control system

- Glue tank and air compressor

Customers can choose or design embossing patterns to match their brand style.

The final roll runs smoothly through the whole line and is ready for cutting.

As part of your toilet paper-making machine setup, this section gives you control over the final roll appearance and texture.

Bandsaw Cutting Machine — A Key Tissue Paper Production Equipment

This bandsaw cutting machine cuts the rewound rolls into different lengths.

As tissue paper production equipment, it plays an important role because cutting quality directly affects customer experience.

The machine works with:

- Accurate blade alignment

- Stable clamping system

- Protection covers for safe operation

It prepares paper rolls for packing and keeps the same cut length for every roll.

Packing Machine — Small Scale Toilet Paper Machine Section

This packing machine is compact and easy to use.

As part of a small-scale toilet paper machine line, it completes the final product:

- The number of rolls per pack can be set by the user

- Works with many bag materials

- Easy to maintain

- Low energy consumption

We provide all machines and free wearable spare parts.

Raw materials such as jumbo toilet tissue rolls and paper cores can be included with your order if needed.

For more details on this Semi-Automatic Toilet Paper Machine production line, please get in touch with us or send an inquiry. We reply within 24 hours.

Technical Specifications of Semi-Automatic Toilet Paper Machine

| Model | YG-1880 | YG-3000 |

| Max Roll width | 2100mm | 2900mm |

| Finished product diameter | 60-150mm Adjustable | Adjustable |

| Roll Diameter | 1880mm | 3000mm |

| Rewinding speed | 0-200 m/min | 0-400 m/min |

| Total power | 4KW | 8kw |

| Machine weight | 3500kg | 4000kg |

Working Principle Of The Semi-Automatic Toilet Paper Machine

The production flow is simple and smooth:

- Jumbo roll loading and unwinding

- Embossing and perforating create roll texture and tear lines

- Automatic rewinding forms small rolls

- Manual cutting using the bandsaw machine

- Packing options for market sale

Roll size and sheet count can be changed to meet different market demands.

Key Features Of Our Semi-Automatic Toilet Paper Machine

- Stable performance with consistent roll formation

- Adjustable perforation and embossing to match customer needs

- Durable parts and energy-saving motors for long service life

- Safety guards and user-friendly controls for worry-free operation

These features help build trust with your end customers and support long-term business growth.

Advantages For Small And Medium Manufacturers

Many buyers choose semi-automatic machines because they offer:

- Lower machine cost compared with full-automatic lines

- Simple operation, short learning time

- Scalable output, you can add automation later

- Reduced labor needs, but still high efficiency

This makes it easy to enter the market without taking too much financial risk.

Semi-Automatic Tissue Paper Machine Price Factors

The semi-automatic tissue paper machine price depends on several factors:

- Machine model and configuration

- Motor power and energy efficiency

- Embossing pattern type and roll size options

- Cutting machine precision

- Packing machine automation level

Semi-automatic equipment offers a clear cost advantage for new investors when compared with full-automatic lines.

Application Scenarios Of Tissue Paper Production Equipment

A Toilet Paper Machine supports many business types:

- Local tissue factories and small plants

- Supermarkets launching private tissue brands

- OEM / ODM bathroom tissue suppliers

- Regional distributors expanding their catalog

This flexibility gives you more marketing possibilities.

How To Choose The Right Semi-Automatic Toilet Paper Machine

Consider these points before purchase:

- Expected production capacity

- Roll size and packing style

- Spare parts support and after-sales service

- Worker training and installation needs

- Space planning and layout design

Choosing the correct model helps you avoid extra cost later.

Why Choose Us As Your Toilet Paper Production Equipment Supplier

We support your business with:

- Export experience, CE / ISO certification

- Custom machine settings for your target market

- One-stop service: installation, training, spare parts, maintenance

- Case studies showing real working results and strong performance

Many buyers start with a Semi-Automatic Toilet Paper Machine and later upgrade with us to a full-automatic line as their output grows.

Frequently Asked Questions

1. How many workers are needed for this production line?

Two to four workers are sufficient for stable daily operation.

2. Can I choose different roll sizes?

Yes, roll size and sheet count can be adjusted to meet market needs.

3. What raw materials should I buy first?

We can send jumbo toilet tissue rolls and paper cores with your machines to help you start faster.

4. How long does installation take?

Normally 3–7 days depending on local conditions.

5. What is the expected return time?

Most small factories recover costs in 6–12 months, depending on sales volume.

6. Can this line upgrade to full-automatic later?

Yes, the system is expandable. You can add automatic packing or conveyor systems when your business grows.

7. Are spare parts easy to replace?

Yes, we include free wearable parts and offer long-term parts support.

WhatsApp/WeChat/Phone: 86 138 3715 9132