A Square Bottom Paper Bag Machine makes strong paper bags with a flat bottom. The machine uses rolls of paper to form bags for food, retail, and delivery. The main advantage of a square bottom is load support. These bags stand up by themselves. They hold heavy items better than V-bottom bags. The Square Bottom Paper Bag Machine is ideal for grocery stores, bakeries, and gift packaging.

WhatsApp/WeChat/Phone: 86 138 3715 9132

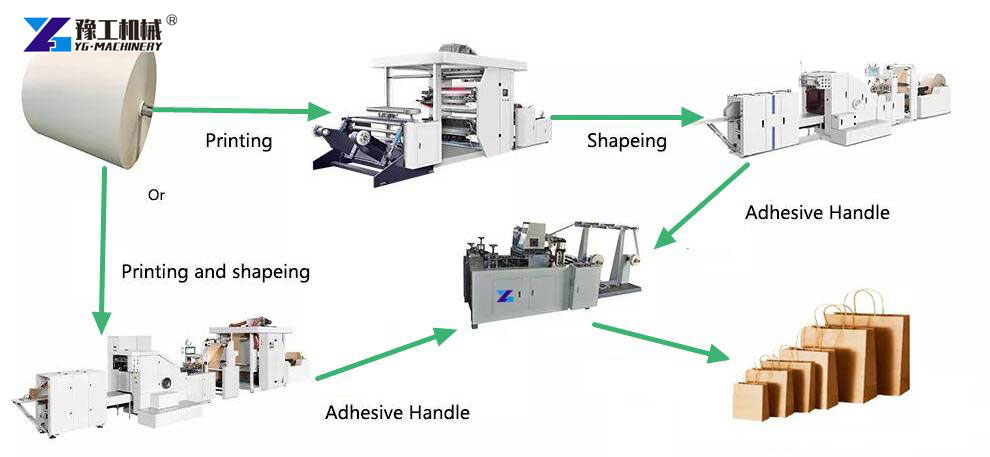

Paper Bag Making Machine: How It Works

A paper bag-making machine turns a paper roll into finished bags. The main steps are:

- Feeding paper from the roll.

- Printing or embossing (optional).

- Cutting and folding the bag body.

- Forming and sealing the square bottom.

- Counting and stacking finished bags.

Key parts of the paper bag making machine:

- Unwind and feeding unit.

- Printing and registration unit (optional).

- Folding and gluing stations.

- Bottom forming station for square bottoms.

- PLC control and safety covers.

This section explains the process in simple words. The Square Bottom Paper Bag Machine keeps steps steady. The machine is built for long runs and stable output.

Technical Specification of Square Bottom Paper Bag Machine

| Model | YG-FD220 |

| Cutting Length | 190-370mm |

| Paper Bag Width | 220mm |

| Bottom width | 50-105mm |

| Paper bag thickness | 50-130g/㎡ |

| Mechanical speed | 30-260pcs/min |

| Paper bag manufacturing speed | 30-200pcs/min |

| Paper roll width | 280-640mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 11.5kw |

| The whole machine pressure | 0.5MPa-0.8MPa |

| Total Weight | 6000kg |

| Overall size | 8500*3500*2200mm |

Key Features of Square Bottom Paper Bag Machine

The Square Bottom Paper Bag Machine combines speed and accuracy. Main features include:

- Precise Folding: Servo controls ensure exact bottom shape.

- Strong Glue System: Durable joints for heavy loads.

- Material Flexibility: Works with kraft paper, coated paper, and art paper.

- PLC Touch Control: Easy to set bag size and speed.

- Compact Footprint: Save factory space.

Technical advantages:

- Low Energy Use: Efficient motors and optimized heating.

- Easy Maintenance: Quick access panels and common spare parts.

- Stable Output: Minimal stops for jams or set changes.

These features help factories keep cost low and quality high. Use these lists on your product page to show benefits clearly.

Kraft Paper Bag Machine: Materials And Flexibility

Kraft paper is popular for eco bags. A kraft paper bag machine makes strong, natural-looking bags. Benefits of Kraft bags:

- Biodegradable and recyclable.

- Good for heavy goods like bread, coffee, and produce.

- Great for brand image and eco labels.

The Square Bottom Paper Bag Machine adapts to kraft paper thickness from 40 to 150 gsm. It can also handle laminated kraft for wet or oily products. This flexibility supports many markets and makes your line more useful.

Automatic Paper Bag Machine: Control And Efficiency

An automatic paper bag machine reduces labor and raises output. Main automation highlights:

- Auto feeding and cutting.

- Auto glue and bottom forming.

- Auto counting and stacking.

- Quick changeover with memory presets.

Benefits of automation:

- Less manual work and lower labor cost.

- Faster set up when changing bag sizes.

- Stable quality for long production runs.

The Square Bottom Paper Bag Machine with automatic features is a good fit for high-volume plants and brands that need consistency every day.

Applications And Industry Uses

Square-bottom bag manufacturing fits many sectors. Typical applications:

- Supermarkets and retail shopping bags.

- Bakery and food packaging—bread, cakes, and takeaway meals.

- Gift and boutique bags with printed logos.

- Industrial packing for light goods or parts.

Why brands choose square bottom bag manufacturing:

- Stronger load capacity.

- Better display on shelves.

- Room for full color printing and branding.

This machine helps businesses move from plastic to paper with a professional look.

Why Choose Our Square Bottom Paper Bag Machine

Choose this Square Bottom Paper Bag Machine for real savings and fast ROI. Reasons include:

- Solid Frame: Long life and stable motion.

- Energy Saving Design: Lower running cost.

- CE Certified: Meets European safety and export rules.

- Factory Support: Technical guidance and spare parts.

- Custom Options: Size range, printing, and handles.

List of value points:

- Factory direct price and transparent warranty.

- Easy training and online support.

- Fast spare part delivery for minimal downtime.

These points help you decide with confidence. The Square Bottom Paper Bag Machine is built for steady production and simple maintenance.

How To Get Your Customized Paper Bag Machine

Ready to add a square-bottom bag line? Steps to order:

- Send your bag size, paper type, and required speed.

- Get a tailored quote and suggested model.

- Arrange a factory test video or an on-site demo.

- Confirm order and schedule production.

- Receive the machine with manual and remote setup help.

YG offers remote commissioning and video tests. You can request sample trials before shipment. For custom printing or handle options, the team will propose the best configuration.

WhatsApp/WeChat/Phone: 86 138 3715 9132