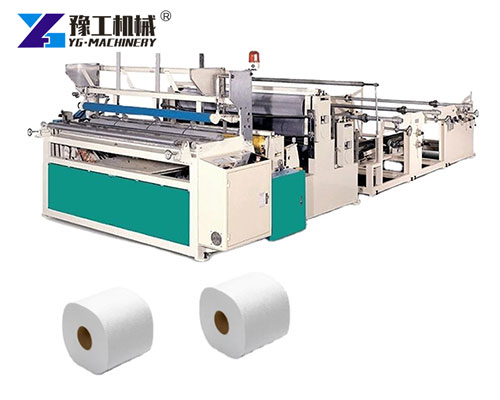

What Is a Tissue Paper Machine

A Tissue Paper Machine is specialized equipment used for producing toilet paper, facial tissue, and kitchen paper rolls. It is designed for high efficiency and continuous operation, helping manufacturers achieve large-scale paper production with consistent quality.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Technical Parameters of the Tissue Paper Machine

| Model | YG1575 |

| Applicable Raw Paper | 2-3 plies 14~23gsm, Wood pulp paper |

| Raw Paper Width | Max 2100mm |

| Raw Paper Dia | Max2200mm |

| Finished Size | Φ60~130 mm |

| Finished Core Dia | Φ35mm-Φ50mm |

| Raw Paper Core Dia | 3″(76.2 mm) |

| Perforation | Spiral perforating knife, Chain wheel positioning |

| Production Speed | 200 m/min |

| Parameter Design | LCD Touch Screen |

| Control | PLC |

| Paper Feeding | 3 Unwinding stands, controlled by pneumatic |

| Air Pressure | 0.5 MPs |

| Power | 380V,50hz |

| Packaging | Wooden box |

High Production Efficiency of the Toilet Paper Production Line

Our toilet paper production line integrates automatic feeding, embossing, and rewinding into a single unit.

Key benefits include:

- Continuous operation with minimal downtime.

- Suitable for large factories requiring high output.

- Intelligent control systems for stable and smooth production.

Stable And Durable Structure of the Tissue Paper Making Machine For Sale

The tissue paper making machine for sale is built with stainless steel or reinforced carbon steel, ensuring long-term durability.

It operates smoothly, with reduced vibration and wear. The design emphasizes easy maintenance and a long service life, even under heavy workloads.

Energy-Saving Operation of an Automatic Tissue Paper Machine

Our automatic tissue paper machine adopts an advanced power management system that minimizes electricity consumption and improves output efficiency.

Benefits include:

- Optimized energy ratio for lower production costs.

- Smart adjustment based on production demand.

- Long-term savings for manufacturers.

Types Of Tissue Converting Equipment

- Fully Automatic Tissue Paper Machine:

- Complete automation from raw material feeding to finished roll packaging.

- Ideal for large-scale factories seeking high productivity.

- Semi-Automatic Tissue Paper Machine:

- Lower investment, easy to operate.

- Suitable for small and medium-sized producers.

Both types of tissue converting equipment are designed to improve efficiency while maintaining flexibility in operation.

Product Advantages of the Tissue Paper Machine

- Cost-Effective Production: Reduces labor and raw material waste.

- High-Quality Paper Output: Produces soft, absorbent, and uniform paper rolls.

- Flexible Customization: Adjustable width, output, and control system.

- Safe and Reliable: Equipped with overload protection and emergency stop features.

Applications Of The Tissue Paper Machine

This machine is widely used in:

- Toilet paper manufacturing plants.

- Hotel and hospitality supply chains.

- Household tissue brands.

It supports the production of multi-layer, embossed, or printed tissue rolls to meet diverse market needs.

Why Choose Our Tissue Paper Making Machine

- Professional Manufacturer: Years of experience in paper machinery, exporting to Asia, Africa, the Middle East, and Europe.

- One-Stop Service: From design and production to installation and training.

- Complete Solution: Full toilet paper machine with auxiliary systems and spare parts.

Customer Feedback

Many users report that the Tissue Paper Machine runs smoothly with low maintenance costs.

They are satisfied with:

- High paper quality and consistent roll size.

- Easy operation and training support.

- Reliable after-sales service and fast spare part supply.

How To Start Your Tissue Paper Production Line

- Define your production capacity and paper type.

- Choose the right Tissue Paper Machine model and configuration.

- Contact our team for quotations and technical advice.

- Arrange shipment and installation support.

With YG’s professional guidance, starting a profitable tissue production business is simple and efficient.

WhatsApp/WeChat/Phone: 86 138 3715 9132