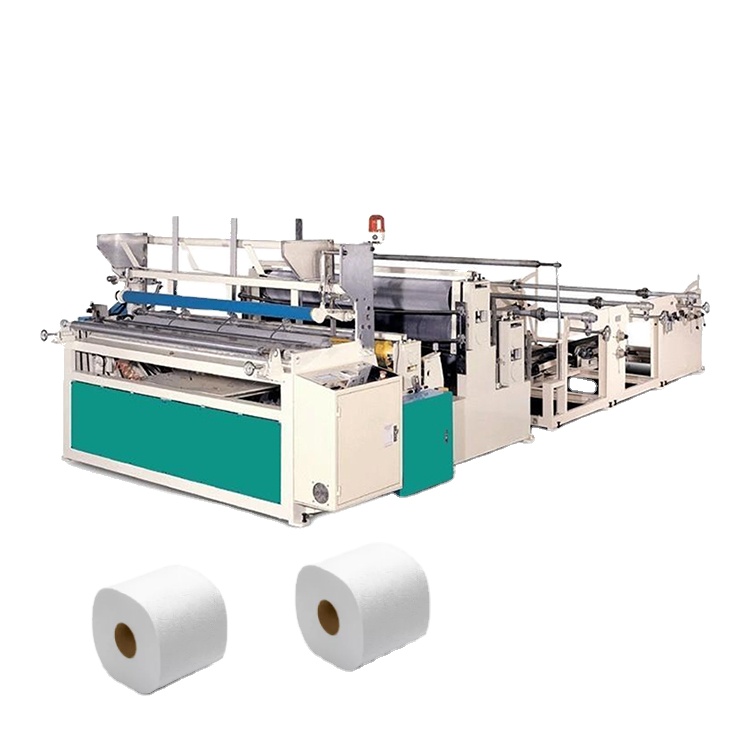

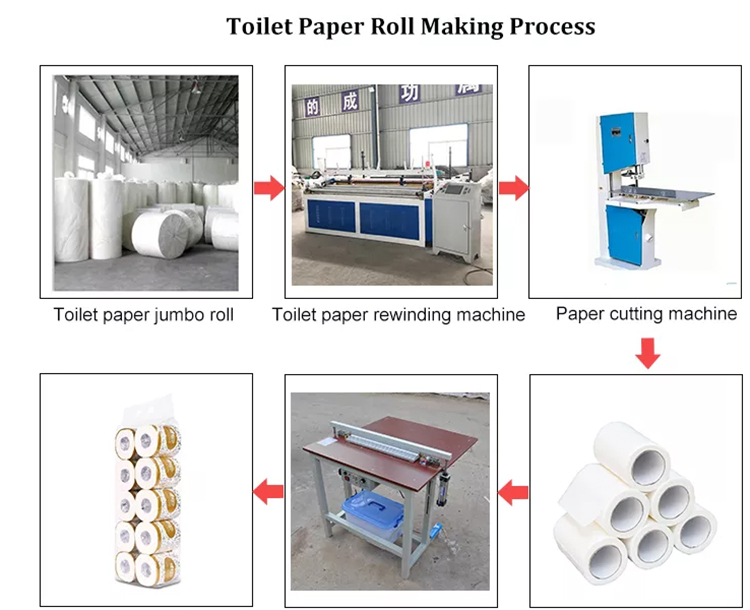

The toilet roll machine is a vital piece of manufacturing equipment engineered to produce toilet paper rolls. efficiently converting raw materials into various toilet paper products. Integrating functions like rewinding, embossing, cutting, and wrapping, it streamlines production to meet global domestic and commercial demand. YG Machinery, a leading Chinese supplier, offers diverse toilet tissue making machine types and solutions, ensuring reliable, high-output production for manufacturers.WhatsApp/WeChat/Phone: 86 138 3715 9132

Toilet Paper Machine parameter

| Machine model | YG-1575/1880/2100/2400/2800/3000 |

| Base paper roll diameter | 1200mm (Please specify) |

| Jumbo roll core diameter | 76mm (Please specify) |

| Punch | 2-4 knife, spiral cutter line |

| Control system | PLC control, variable frequency speed control, and touch screen operation |

| Product range | core paper, noncore paper |

| Drop tube | manual and automatic (optional) |

| Working speed | 150-280 m/min |

| Power | 220V/380V 50HZ |

| Embossing | Single embossing, double embossing |

| Finished product launch | Automatic |

Features of Toilet Paper Machines

- High Efficiency: Modern machines operate at high speeds, producing hundreds of rolls/minute to boost factory output, ideal for meeting surging global demand.

- Automation: Fully automated functions—cutting, embossing, packaging—reduce manual labor, minimize errors, streamline production for 24/7 operation.

- Customization: Adjust roll size, paper thickness, and embossed patterns (e.g., floral or textured designs) to cater to diverse market preferences, enhancing product appeal.

- Durable: Built with heavy-duty steel and corrosion-resistant components, these machines withstand continuous use, ensuring a long service life and low replacement costs.

- Energy Efficiency: Equipped with low-energy motors and smart power systems, they reduce electricity consumption while maintaining high-speed performance, supporting eco-friendly production.

- User-Friendly: Modular designs and accessible components simplify routine checks and part replacements, minimizing downtime and ensuring hassle-free upkeep for operators.

Tissue machine production cost

The production cost of using a Toilet Paper Machine includes several aspects:

- Machine Purchase: The initial investment in a Toilet Paper Machine For Sale can be significant. The price depends on the machine’s capacity, features, and brand. High-end, fully automated machines are more expensive than basic models.

- Raw Materials: The cost of raw materials, such as pulp, also contributes to the overall production cost. The price of pulp can fluctuate depending on market conditions, availability, and quality.

- Energy Consumption: Toilet Paper Machines require energy to operate. Electricity is the main source of energy, and the amount of electricity consumed depends on the machine’s power rating and operating time.

- Labor: Although many machines are automated, some level of human labor is still required for machine operation, maintenance, and quality control. Labor costs vary from region to region.

FAQ

How long does a Toilet Paper Machine last?

A well – maintained Toilet Paper Machine can last for 10 – 15 years or even longer. Regular maintenance, including cleaning, lubrication, and replacement of worn-out parts, is crucial for its long-term performance.

Can I use different types of pulp in the same machine?

Most toilet paper-making machines are designed to handle different types of pulp, such as wood pulp, recycled pulp, and bamboo pulp. However, it is important to follow the manufacturer’s guidelines to ensure optimal performance.

What is the production capacity of a Toilet Paper Machine?

The production capacity varies depending on the machine model. Small – scale machines may produce a few hundred rolls per hour, while large – scale industrial machines can produce thousands of rolls per hour.

Are they hard to operate?

Toilet Paper Machines are designed to be user-friendly. With proper training, operators can quickly learn how to operate the machine. However, it is important to follow safety procedures and maintenance schedules.

WhatsApp/WeChat/Phone: 86 138 3715 9132