Modern hygiene products require speed, safety, and stable quality. A Wet Wipes Machine is designed to meet these demands by combining automated production, precise liquid control, and clean packaging in one continuous system. For manufacturers targeting baby care, medical use, or household cleaning markets, the right machine helps reduce labor costs, improve product consistency, and scale production efficiently while meeting strict hygiene standards.

WhatsApp/WeChat/Phone: 86 138 3715 9132

What Is A Wet Wipes Machine

A Wet Wipes Machine is industrial equipment used to produce pre-moistened wipes made from nonwoven fabric. Its core function is to process raw materials into finished wet wipes through automatic feeding, liquid application, cutting, folding, and sealing.

In modern hygiene product manufacturing, this machine plays a key role by replacing manual operations with stable automation. It helps manufacturers control moisture content, wipe size, and packaging quality, which are critical for user safety and brand trust. As global demand for hygiene products continues to grow, automated production becomes a basic requirement rather than an option.

How A Wet Wipes Machine Works

A complete wet wipes production process is designed to be smooth, clean, and continuous.

Raw material feeding

Nonwoven fabric rolls are loaded into the machine and guided through a stable feeding system. Tension control keeps the fabric flat and aligned.

Liquid dosing and impregnation

Purified water, lotion, or disinfectant solution is prepared and applied evenly. Accurate pumps ensure each wipe has the same moisture level.

Folding, cutting, and stacking

The wet fabric is folded into the required shape, then cut into uniform sizes. Wipes are stacked or rolled based on the final packaging type.

Packaging and sealing process

Finished wipes are transferred to the packaging unit, where they are sealed to keep moisture and hygiene intact.

This automatic flow improves efficiency and reduces human contact with the product.

Key Components Of An Industrial Wet Wipes Equipment System

A high-quality production line is built from several key systems that work together.

- Nonwoven fabric system

Ensures smooth feeding and stable material control. - Liquid control system

Maintains correct formula ratio and consistent moisture. - Cutting and folding units

Produce clean edges and accurate wipe sizes. - Packaging and control system

Handles sealing, counting, and real-time monitoring.

Reliable industrial wet wipes equipment focuses on durability, easy maintenance, and hygienic design, especially for long-term operation.

Types Of Wet Wipes Machines In Manufacturing Lines

Different markets require different machine configurations. A professional wet wipes manufacturing machine can be customized to support multiple formats.

Single sachet wet wipes machine

Used for hotels, restaurants, and travel packs.

Main Parameters

Power Supply: 220V 50HZ

Power: 4.0KW

Applicable Material: Spunlace Nonwoven Fabric

Material Weight: 40~80 g/m²

Material Specifications: ¢ 1000 x (150~260) mm (diameter x width)

Unfolded Dimensions: (150~270) x (140~260) mm (length x width)

Folded Dimensions: (60~135) x (35~70) mm (length x width)

Roll Film Material: OPP/PE, PET/PE Composite

Production Speed: 80~230 sheets/min

Slitting Mechanism: Individual Master Roll

Folding Method: Z, W, Shaped Folding

Equipment Dimensions: 4500 x 1200 x 1700 mm (length x width x height)

Control System: 5.7-inch Touch Screen, PLC Control System

Canister wet wipes machine

Designed for roll-type wipes used in medical or industrial settings.

Main Parameters

Power Supply: 380V 50Hz

Total Power: 9KW

Applicable Materials: Cleanroom paper, nonwoven fabric

Material Weight: 30-60 g/m²

Maximum Raw Material Size: 1200X1500 mm

Maximum Size of Single Wet Wipe: Adjustable

Roll Size (mm): 120 x width

Rewinding Speed: 90 m/min

Machine Weight: 2000 kg

Machine Dimensions (mm): 3405X2108X2032

Soft pack wet wipes machine(5-30pcs)

Common for baby wipes and household cleaning wipes.

Main Parameters

Production Speed: 900 sheets/minute

Applicable Raw Materials: Spunlace nonwoven fabric, thermally bonded nonwoven fabric

Material Weight: 30-120 g/m²

Folding Method: “Z”, “W”, or “N” type

Counting Method: Automatic counting, variable sheet stacking system

Tissue Size: L70-260mm, W80-280mm

Packaging Film Size: L80-300mm, W80-250mm

Finished Product Size: L80-300mm, W30-120mm, H1-65mm

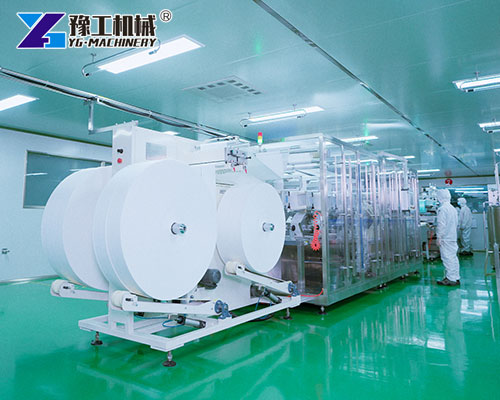

Multi-lane high-speed production lines(3500~4000 pieces/min)

Suitable for large factories with high daily output needs.

Main Parameters

Power Supply: 380V 50HZ

Power: 18KW

Applicable Material: Spunlace nonwoven fabric

Material Weight: 40~80 g/m²

Unfolded Size: (180~220) x (200~220) mm (Length x Width)

Folded Size: (120~250) x (180~220) mm (Length x Width)

Production Speed: 3500~4000 pieces/min

Folding Method: Z-shaped or pull-out folding (pull-out or non-pull-out)

Equipment Dimensions: 15000x3500x2400mm (Length x Width x Height)

Weight: 15000KG

Counting Method: Automatic counting, variable piece stacking system

Control System: PLC control system with PC color touch screen display

Humidification System: Double-stirring stainless steel tank

Choosing the correct type helps avoid overinvestment and improves production efficiency.

Main Applications Of Wet Wipes Machines

Wet wipes are used in many daily and professional environments.

Baby care and personal hygiene

Soft, skin-friendly wipes for infants and adults.

Medical and disinfectant wipes

Used in hospitals, clinics, and public health environments.

Household cleaning wipes

For kitchens, floors, and furniture surfaces.

Industrial and surface cleaning wipes

Heavy-duty wipes for factories and workshops.

A flexible baby wipes making machine can often be adjusted to produce other wipe types, helping manufacturers expand their product range.

Advantages Of Using An Automatic Wet Wipes Production Line

An automatic wet wipes production line offers clear benefits for growing manufacturers.

- Higher production speed with stable output

- Consistent wipe size and moisture level

- Reduced labor and operating costs

- Better hygiene with less manual contact

- Easy adjustment for different products

Automation improves both efficiency and long-term cost control, especially for export-oriented factories.

When A Wet Wipes Machine May NOT Be Suitable

Although efficient, a Wet Wipes Machine is not the best choice in every situation.

- Small trial production with very low volume

- Handmade or artisanal wipe products

- Extremely limited factory space or power supply

- Frequent formula changes in small batches

In these cases, semi-automatic solutions may offer better flexibility and lower investment risk.

How To Choose The Right Wet Wipes Machine

Selecting the right equipment depends on real production needs.

- Output capacity requirements

Match machine speed to your target daily output. - Packaging format

Choose a compatible wet wipes packaging machine for sachets, soft packs, or canisters. - Automation level

Higher automation reduces labor but requires stable planning. - Compliance and after-sales support

Ensure the machine meets export standards and includes technical service.

A clear selection process helps avoid costly upgrades later.

Why Choose A Professional Wet Wipes Machine Manufacturer

Working with an experienced manufacturer brings long-term value.

- Stable equipment design for continuous operation

- Customization based on product positioning

- Technical training for operators

- Reliable after-sales support and spare parts

A professional supplier understands production challenges and helps customers build sustainable, scalable businesses with confidence.

WhatsApp/WeChat/Phone: 86 138 3715 9132