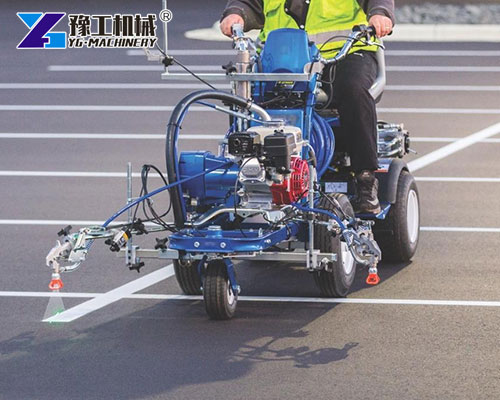

The Road Painting Machine is essential for marking roads, highways, parking lots, and industrial zones. It ensures that traffic lines are applied quickly, accurately, and with long-lasting visibility. YG’s road painting solutions are designed to meet the demands of both small contractors and government agencies, offering precision, speed, and durability in a wide range of working environments.

Whether you need thermoplastic, cold paint, or two-component applications, YG provides reliable options tailored to various surfaces and climates. Our road marking equipment improves project efficiency, safety, and cost-effectiveness.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Technical Parameters of the Thermoplastic Road Painting Machine

| Model | YG-380 |

| Thermoplastic Tank | 100Kg/100L |

| Marking Width | 50~200mm(Adjustable) |

| Marking Equipment | 100mm Marking Shoe |

| Knife Underframe | Carbide |

| Marking Thickness | 1~3mm |

| Tire | Alloy Wheel, a special heat-resistant rubber |

| Heating Method | Liquefied petroleum gas |

| Heating Temperature | 0~250ºC |

| Marking Temperature | 180ºC |

| Dimension | 1200*900*950mm |

| Weight | 100kg |

Applications of Road Painting Machines

Road Painting Machines are versatile tools with a wide range of applications in maintaining and constructing roadways and other paved areas. Some key applications include:

- Highway Lane Marking: Applying durable lines to delineate traffic lanes on highways and major roads, ensuring safe vehicle flow.

- Urban Road Marking: Painting lane dividers, crosswalks, parking space lines, and other markings on city streets to manage traffic and pedestrian movement.

- Parking Lot Striping: Creating clear and organized parking spaces in commercial and private parking areas to maximize capacity and ease of use.

- Airport Runway Marking: Applying highly visible and durable markings on airport runways and taxiways to guide aircraft safely.

- Sports Field Marking: Painting lines and markings on athletic fields and tracks for various sports, requiring precision and durability.

- Traffic Guidance on Construction Sites: Marking temporary lanes and safety zones on construction sites to ensure the safe movement of vehicles and personnel.

Features Of YG Road Painting Machines

YG’s road painting machines are known for their efficiency, accuracy, and ease of use. They’re engineered with practical features to meet diverse customer needs.

- Adjustable Line Width and Thickness – Allows operators to adapt to various marking standards.

- Thermoplastic or Cold Paint Compatibility – Offers flexibility based on project type.

- Efficient Heating System – Thermoplastic models come with quick-melt kettles to reduce prep time.

- Durable Materials – Anti-corrosion steel and reinforced wheels ensure long service life.

- Precision Control – An Accurate spray or extrusion system ensures clean line edges.

- Compact Design – Allows for smooth operation even in tight or complex marking zones.

These machines are user-friendly and designed for maximum output with minimal downtime.

Working Principle Of A Road Striping Machine

A road striping machine works by applying a consistent layer of marking material on road surfaces using a controlled delivery system. The principle varies depending on the type of machine (cold paint, thermoplastic, or two-component).

- Material Loading – Load paint or thermoplastic into the tank or preheater.

- Heating or Stirring – In thermoplastic models, heat and stir the material to maintain proper viscosity.

- Pressurized Delivery – Pump the material through a nozzle or extruder onto the road surface.

- Line Adjustment – Operators can control line width, spacing, and alignment using onboard settings.

- Bead Dispensing (Optional) – Automatically spray glass beads for reflective markings.

This method ensures uniform lines with strong adhesion and quick drying, even in high-traffic areas.

Advantages Of Using A Road Line Marking Machine

Investing in a high-quality road line marking machine offers numerous benefits for roadwork contractors and municipalities:

- Time-Saving – Complete large areas quickly with less manpower.

- Cost-Effective – Reduces labor and material waste, increasing overall profitability.

- High Visibility – Produces sharp, reflective lines that last longer in traffic conditions.

- Adaptability – Suitable for various environments, including concrete, asphalt, and indoor surfaces.

- Reduced Errors – Built-in guide systems minimize deviation and line distortion.

- Environmental Efficiency – Many models use eco-friendly paints and reduced-emission engines.

YG Manufacturer’s Range of Road Machinery

YG Manufacturer offers a comprehensive range of high-quality road machinery designed to meet diverse construction and maintenance needs. Our offerings extend beyond the Road Painting Machine and include: Road Roller, Asphalt Paver, Concrete Mixer, Crack Sealing Machine, Road Milling Machine, and Road Line Marking Machine.

Our commitment to quality and innovation ensures that all our road machinery, including our efficient road striping machine models, delivers reliable performance and long-term value for our customers. We strive to provide comprehensive solutions for all your road construction and maintenance requirements.

WhatsApp/WeChat/Phone: 86 138 3715 9132