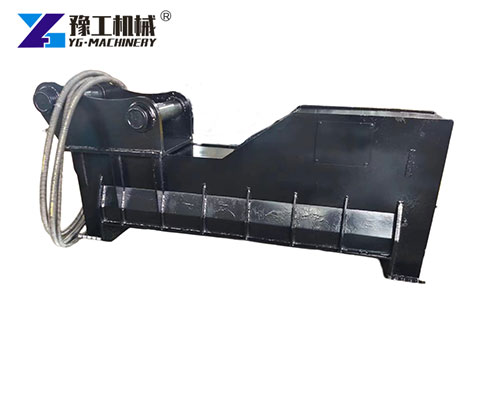

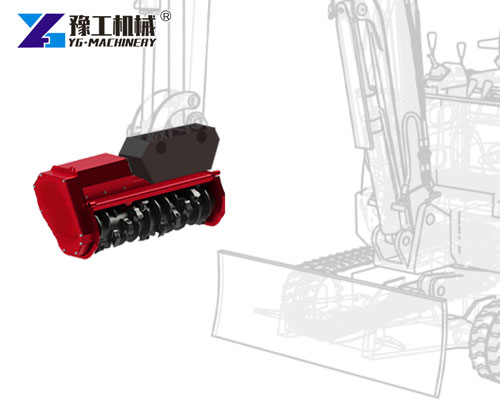

The Mulcher for Excavator from YG Machinery is a robust hydraulic attachment designed to shred trees, brush, and vegetation efficiently. Equipped with heavy-duty rotors and replaceable carbide teeth, it fits excavators from 1 to 25 tons, ideal for forestry, land clearing, and construction site preparation. With durable design, easy maintenance, and factory direct pricing,

YG mulchers help contractors save time and costs. Explore our models, check specifications, and request a free quote today to get the best solution for your projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Features of the Mulcher for Excavator

A well-designed Mulcher for Excavator combines power with smart engineering to meet diverse job site challenges.

Main features include:

- Heavy-Duty Rotor System – Designed to efficiently handle hardwoods and dense vegetation

- Replaceable Carbide Teeth – Prolong service life and lower maintenance costs

- Adjustable Mounting Bracket – Guarantees compatibility with various excavator brands

- Robust Protective Housing – Protects internal parts and ensures operator safety

- Variable Flow Control – Enhances performance based on hydraulic capacity.

These features make YG’s mulchers a top choice for contractors seeking efficiency and durability on the job.

Applications of Excavator Mulchers

The versatility of an excavator mulcher makes it suitable for a wide array of applications across various industries. Its ability to clear land efficiently and process vegetation on-site provides significant benefits for numerous projects.

Preventing roadside fires

Forestry Management:

- Clearing fire breaks

- Creating access roads

- Thinning overgrown areas for forest health

- Preparing land for reforestation

Land Development & Site Preparation:

- Clearing construction sites

- Preparing the ground for new infrastructure

- Managing rights-of-way for utilities

Agriculture:

- Clearing fence lines

- Managing unproductive land

- Preparing fields for planting

Environmental & Conservation Projects:

- Restoring natural habitats

- Controlling invasive species

- Creating wildlife corridors

Roadside Maintenance:

- Clearing brush along roadways

- Maintaining visibility and safety

Advantages of Using an Excavator Mulcher

Investing in an excavator mulcher for excavator brings a host of advantages that significantly impact project efficiency, cost-effectiveness, and environmental responsibility. These benefits highlight why so many professionals are choosing this powerful attachment.

- Uniform Product: Produces a consistent, finely processed mulch that can be left on site or easily managed.

- Increased Efficiency: Mulching on-site eliminates the need for hauling, burning, or chipping, saving time and labor costs. A single machine can perform multiple tasks.

- Environmental Benefits:

Returns organic material to the soil, improving soil health and preventing erosion.

Reduces the need for chemical herbicides.

Minimizes landfill waste and air pollution from burning. - Enhanced Safety: Reduces manual labor in hazardous environments, improving overall site safety. Operators remain in the cab, away from direct contact with vegetation.

- Cost Savings: Lower fuel consumption compared to multiple machines, reduced transportation costs for debris removal, and minimized disposal fees.

- Superior Accessibility: Excavators can reach difficult or uneven terrain, making mulching possible in areas inaccessible to other equipment.

How an Excavator Forestry Mulcher Works

The Excavator Forestry Mulcher uses the hydraulic system of the host excavator to power a rotating drum equipped with sharp teeth or blades. These components rapidly shred branches, stumps, and bushes into fine mulch.

The hydraulic motor drives the cutting system, which varies in design depending on the model—flail, drum, or disc style. Most models include a protective shroud to contain debris and ensure operator safety.

Operation process:

- Hydraulic power from the excavator is transferred to the mulcher.

- The rotor spins at high speed with durable teeth or hammers.

- As the head moves over vegetation, it cuts and grinds material into mulch.

- The mulch remains on-site to prevent erosion and support soil health.

High-torque, low-RPM models are best suited for tougher terrain and denser brush, while lighter-duty versions work well for softer vegetation.

Buying Guide: Excavator Mulchers for Sale

When browsing Excavator Mulchers for Sale, it’s important to match the attachment to your machine and intended application.

Key selection criteria:

- Excavator Size Compatibility – Check tonnage and hydraulic flow requirements

- Type of Material – Determine whether you’ll handle soft brush, hardwood, or a mix

- Working Environment – Consider width, ground clearance, and terrain type

- Rotor Design – Choose between flail, drum, or fixed tooth heads based on cutting needs

- Maintenance Requirements – Look for easy-access components and serviceable teeth

- After-Sales Support – Ensure reliable customer service, spare parts, and documentation

YG Machinery offers a wide range of models with full support to ensure your equipment performs optimally on every job.

WhatsApp/WeChat/Phone: 86 138 3715 9132