A Roller Conveyor Shot Blasting Machine is a key tool for steel surface treatment. It cleans and removes rust from steel plates, profiles, and pipes. Many makers in shipbuilding, bridge work, and steel structures use it. The machine gives fast, even cleaning. It helps paint and coating stick better.

What Is A Roller Conveyor Shot Blasting Machine?

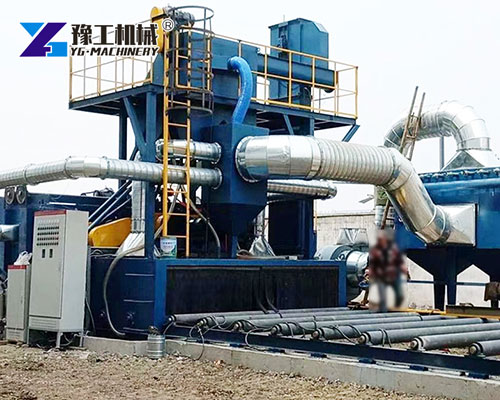

A roll conveyor shot blasting machine (Also called a Conveyor Shot Blasting Machine) uses a roller conveyor to move steel parts through a blasting chamber. High-speed steel shots hit the work surface. The shots remove rust, scale, and old paint. The machine has a blast wheel, shot collectors, and a dust system. It runs as part of a production line. Compared with hand blasting, a conveyor shot blasting machine works faster and is more consistent. It is good for large batches and continuous work.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Product Features Of Steel Plate Shot Blaster

A steel plate shot blaster is built for heavy use. Main features include:

- High Cleaning Rate: Removes scale and rust quickly.

- Roller Conveyor: Smooth feeding for plates and sheets.

- Dust Control System: Lowers dust and keeps the shop clean.

- Durable Parts: Heavy-duty blast wheels and wear liners.

- Custom Size: Can match plate width and thickness.

These features make a steel plate shot blaster ideal for pre-paint and surface prep on production lines.

Application Range For Profile Shot Blasting Equipment

The profile shot blasting equipment works for many steel items:

- Steel Structures: H-beam, I-beam, angle steel, and channels.

- Shipbuilding: Plate cleaning before welding and coating.

- Bridge Fabrication: Remove mill scale on plates and profiles.

- Pipe And Tube Processing: Clean inside and outside surfaces.

Profile shot blasting equipment fits both single-piece and continuous processes. It helps meet coating standards and improves corrosion life.

Advantages Of Automatic Shot Blasting Machine

An automatic shot blasting machine brings big benefits for factories:

- Save Labor: One operator can run long shifts.

- Stable Quality: Same finish for every part.

- High Speed: Large throughput for mass production.

- Energy Saving: Modern drives and closed systems reduce use.

Automatic shot blasting machine models include PLC control and automatic feeding. These designs cut manual loading and lower errors.

YG Support For Industrial Shot Blasting Machine

As an industrial shot blasting machine supplier, YG offers full service:

- Custom Design: We size the rollers and blast wheel for your parts.

- Pre-Delivery Test: Run the machine in the factory before shipping.

- Packing and Shipping: Strong packing to protect parts in transit.

- Installation Support: Remote guidance or on-site engineers if needed.

- Spare Parts and Service: Fast supply of liners, wheels, and media.

YG also offers road shot blasting machines for streets and floor shot blasters for on-site floor prep. This makes it easy to add inner links and solutions for many projects.

How A Roller Conveyor Shot Blasting Machine Helps Production

Using this machine improves many production areas:

- Faster Surface Prep: Less time before painting or welding.

- Better Coating Life: A Clean surface gives strong adhesion.

- Lower Scrap: Consistent cleaning reduces rework.

- Safer Environment: Dust system cuts breathing hazards.

Many customers see higher output and lower overall cost after adding conveyor shot blasting machines to their lines.

Choosing The Right Model — Simple Tips

Pick the right machine with these checks:

- Part Size: Measure max width, length, and weight.

- Throughput Need: How many square meters per hour do you need?

- Media Type: Choose the correct steel shot size for the cleaning level.

- Dust System: Indoor shops need strong collectors.

- Automation Level: PLC and automatic feeding save labor.

Tell your supplier these points and ask for a fitted plan. YG can provide drawings and performance estimates.

Why Choose YG Roller Conveyor Shot Blasting Machine

YG offers durable roller conveyor shot blasting machine units with real factory experience:

- Strong build and long-service components.

- Options for steel plate shot blaster and profile blasting.

- Global export record and after-sales support.

- Competitive price for full production systems.

We also supply floor shot blasters, shot blasting accessories, and mobile road shot blasting units. This helps you build a full surface treatment solution.

Contact Us For A Quote

If your factory needs a Roller Conveyor Shot Blasting Machine, contact YG Machinery. Tell us your part sizes, daily output needs, and dust rules. We will give a tailored plan, machine model, and clear price. Improve steel finish quality and speed with the right conveyor shot blasting machine for your line.

WhatsApp/WeChat/Phone: 86 138 3715 9132