A Hook Shot Blasting Machine is a key tool for metal surface treatment. It cleans castings, forgings, welded parts, and complex components. This machine removes sand, rust, scale, and burrs. It also makes the surface stronger for painting or inspection. Many factories use hook shot blasting machines to save time and improve quality.

What Is A Hook Type Shot Blasting Machine?

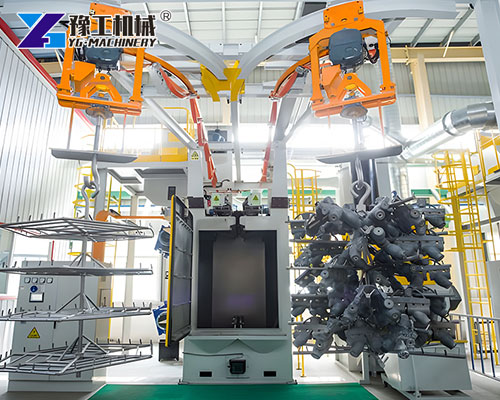

A hook-type shot blasting machine is for hanging workpieces. The parts hang on hooks or baskets. A fan or blast wheel throws steel shot at high speed. The shot hits the surface and cleans or strengthens it. The machine uses a closed chamber and a recycling system. This design is safe and eco-friendly. A hook shot blaster can handle odd shapes and deep recesses well.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Technical Specifications of Hook Shot Blasting Machine

Typical technical data for a hook shot blasting machine (can be customized):

| Component | Specifications/Power |

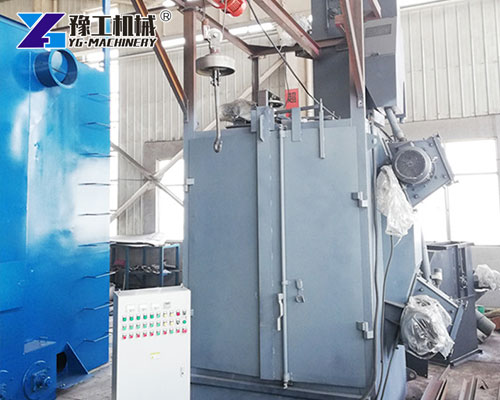

| Main Machine (Q376) | 1700mm (L) × 1400mm (W) × 2200mm (H) |

| Dust Collector Box | 1000mm (L) × 1000mm (W) × 2000mm (H) |

| Overall Dimensions | 1700mm (L) × 1700mm (W) × 4200mm (H) |

| Blasting Wheel (Q376) | 7.5 kW |

| Dust Removal Fan (4-72-4A) | 3 kW |

| Lifting Motor (1-17) | 1.5 kW |

| Rotation Motor | 0.75 kW |

| Trolley | 0.75 kW |

| Hoist | 0.75 kW |

| Total Power | ~23 kW |

We can tune power, hook size, and wheel count to match your parts and output needs.

Applications Of Hook Shot Blaster

The hook shot blaster is used in many industries. Common uses are:

- Foundry Work: Remove sand and scale from cast parts.

- Steel Structure Fabrication: Clean welds and joints on beams.

- Automotive Parts: Prepare parts for painting and plating.

- Wind Power and Machinery: Clean large cast or forged parts.

This machine works for single large parts and many small parts in batch runs. It fits both small shops and large factories.

Key Advantages Of Industrial Shot Blasting Equipment

As advanced industrial shot blasting equipment, the hook machine brings many benefits:

- Full 360° Treatment: Dual hook swing and rotation reach all sides.

- Higher Part Strength: Shot peening adds compressive stress to the surface.

- Fast Automation: PLC control covers loading, blasting, dust cleaning, and unloading.

- Parallel Work Flow: Double-hook design allows loading while another part is cleaned.

- Good Economy: Closed cycle reuses shot and cuts consumable cost.

These points make the hook machine a smart investment for quality and cost.

Working Process

The working process is simple and clear:

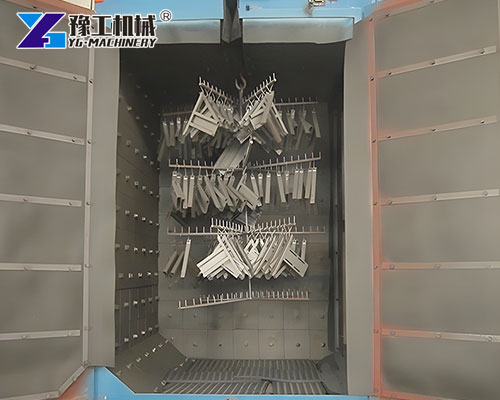

- Hang Part: Operator places the part on the hook.

- Start Program: PLC lowers the door and starts the cycle.

- Rotate And Swing: Hook moves and rotates the part for full coverage.

- High Speed Blasting: Shot hits the surface to clean and peen.

- Recycle And Filter: Shot and dust go to the separators and filters.

- Unload: The Door opens, and the clean part is taken out.

This automatic flow reduces worker time and keeps the work area clean.

Market Demand And Investment Value

A Hook Type Shot Blasting Machine adds clear market value. Treated parts show better fatigue life and paint adhesion. This helps exporters and makers meet client standards. Many shops see shorter lead times and lower rework costs after adding a hook shot blaster. The machine often pays back in months for medium and large-volume shops.

Why Choose Our Hook Shot Blasting Machine Supplier

As a reliable hook shot blasting machine supplier and blasting equipment manufacturer, we offer:

- Custom Design: We make sizes and cycles to fit your parts.

- Quality Components: Manganese steel liners, high chrome blades, and strong motors.

- Full Dust System: Cyclone + bag filter for low emissions.

- Safety Features: Door interlocks, emergency stop, and sensors.

- After-Sales Support: Remote help, spare kits, and on-site training.

We serve foundries, fabricators, and OEMs with tailored hook blast lines.

If you need a Hook Shot Blasting Machine that brings fast cleaning, better part life, and low emissions, contact us today. We provide technical drawings, test videos, and a clear price. Ask for a custom solution from a trusted hook shot blasting machine supplier. Get a quote now and improve your metal finishing process.

In addition to the hook shot blasting machine, we also have the Roller Conveyor Shot Blasting Machine.

WhatsApp/WeChat/Phone: 86 138 3715 9132