A customer from Mexico ordered a Directional Drilling Machine for Sale from YG Machinery. After several discussions to confirm the final specifications, the equipment has been delivered, and the client has already put it into operation with excellent results.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Customer Background

The customer operates an underground pipeline construction business in Mexico, primarily focusing on power and communication pipe-laying projects.

As project volume increased, he needed a Directional Drilling Machine for Sale that offered high efficiency, durability, and energy savings to reduce labor costs.

After researching online, he found YG Machinery and contacted our team for technical consultation and a quotation.

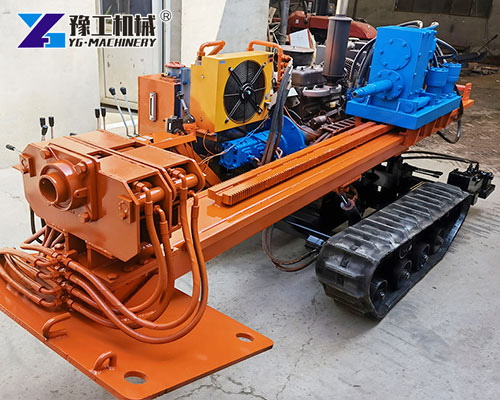

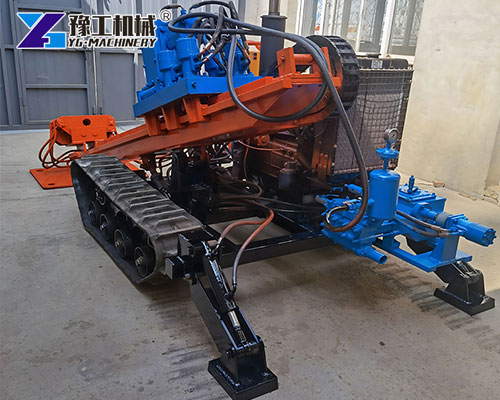

Horizontal Directional Drilling Rig – Model Recommendation

YG’s engineering team recommended the YG-320 Horizontal Directional Drill Rig based on local soil conditions and drilling depth requirements.

Technical Parameters

| Model | YG-320 |

| Engine rated power | 140KW/160KW |

| Push and pull | Cylinder |

| Maximum reaming hole diameter | Φ800mm |

| Drill rod length (single) | 3m |

| Drill pipe diameter | Φ73mm |

| Drill angle | 10-20° |

| Maximum mud flow | 320L/min |

| Maximum mud pressure | 80bar |

| Overall quality | 11500kg |

| Dimensions | 7.1*2.25*2.45m |

To better serve the client’s operators, YG customized the control panel and display language according to local needs.

HDD Drilling Machine Shipment and Delivery Process

After production was completed, the HDD drilling machine underwent strict performance testing and rust-proof treatment.

All critical components were carefully packaged to ensure safe transport.

The shipment was arranged via sea freight to a Mexican port, with a total transit time of around 35 days.

Upon arrival, YG’s technical team provided remote installation guidance and video training to help the customer start drilling operations quickly.

Customer Feedback on Underground Pipe Drilling Machine

The underground pipe drilling machine has been performing very well during the customer’s first 10 km communication pipeline project.

Key highlights from the customer feedback include:

- High Efficiency: Completed tasks 30% faster than conventional drilling methods.

- Low Maintenance Cost: A Reliable hydraulic system minimizes downtime.

- Easy Operation: The Smart control system helps operators work efficiently.

The customer was highly satisfied and has already planned to order two more machines for upcoming projects.

Directional Bore Machine Key Features

YG’s directional bore machine is built with advanced materials and technology to handle various soil types and drilling depths.

Its standout features include:

- High Drilling Torque: Suitable for various soils, including clay and sand.

- Stable Hydraulic System: Ensures continuous and reliable operation.

- Compact Design: Perfect for construction in tight urban spaces.

- Automatic Rod Loader: Improves drilling rod change efficiency.

Trenchless Drilling Equipment Export Experience

YG Machinery has rich experience exporting trenchless drilling equipment to many countries, including the United States, Chile, the Philippines, and Saudi Arabia.

We offer complete customization options based on client requirements, such as power system type, drill rod length, and control system language.

Our professional engineering team ensures smooth project delivery and continuous technical assistance after installation.

WhatsApp/WeChat/Phone: 86 138 3715 9132