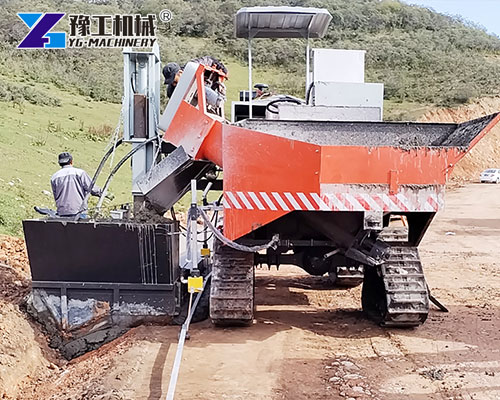

A road construction company from South Africa recently purchased a YG20 Slipform Curb Machine for Sale from YG Machinery. The customer has already received the machine and tested it on a local road project. After several days of work, the feedback was highly positive — the machine showed strong stability, smooth forming, and high working efficiency.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Customer Background and Project Needs

The South African customer specializes in municipal road construction and urban infrastructure. In recent years, they have been expanding into large-scale concrete curb projects. The company needed a Slipform Curb Machine for Sale that could:

- Continuously form concrete curbs on-site;

- Adapt to various curb shapes and dimensions;

- Deliver a smooth, consistent curb finish without cracks or gaps;

- Operate efficiently under local environmental and material conditions.

Their goal was to replace traditional manual curb construction with a concrete curb machine to reduce labor costs and improve productivity.

Technical Parameters of YG20 Slipform Curb Machine for Sale

After understanding the customer’s working conditions, YG engineers recommended the YG20 Slipform Curb Machine. This model is designed for mid- to large-scale road curb projects and is well-suited to South African job sites.

| Model | YG-20 | ||

| Length*Width*Height | 5200*2400*2800mm | ||

| Unladen mass | About 7000kg | The deadweight is greater, the crawler grip is raised, the construction stability is improved, the climbing and sliding formwork flatness, and the slope is free from interference from external factors | |

| Construction scope | Width ≤ 2000mm (road shoulder, ditch), height ≤ 600mm (kerbstone, curbstone) | ||

| Hopper volume | 1m³ | ||

| engine | Rated power | 65kw | Inline 4-cylinder turbocharged diesel engine (for high altitude areas, increased power output) |

| Operating voltage | AC380v | ||

| Startup form | Electric start | ||

| Rated speed | 1500rpm | ||

| Heat dissipation form | Water cooling | ||

| Molding method | High-frequency vibrator (suitable for plastic concrete) | Formed shoulders and side ditches have higher strength | |

| Attached vibration motor (suitable for dry, hard concrete) | Can be paved with curbstones and higher curbstone heights | ||

| Automatic leveling system (imported DLS, optional) | Leveling range ±40mm | Imported components, temperature compensation, overvoltage, and overcurrent protection | |

| Steering form | Dual automatic steering system (imported DLS, standard) | Imported components, temperature compensation, overvoltage, and overcurrent protection | |

| Manual steering wheel (hydraulic steering gear) | |||

| Minimum turning radius | 6800mm | ||

| Paving and transfer speed | 1m-10m/min | Frequency conversion speed regulation can achieve a wide range of stepless adjustment of paving and transfer speed | |

| Travel drive form | Full-time four-wheel drive | When the road slope is ≤5%, a fully loaded 15m3 tank truck can be used for construction, and the slipform machine connection construction can be realized. | |

| Screw feeder drive type | High torque hydraulic gerotor motor | Ensure the continuous feeding of concrete, the screw feeder will not be stuck by large stones, and the concrete will be mixed twice to improve the workability of the concrete. | |

YG also provided a set of custom concrete curb forming molds according to the client’s design drawings. The flexibility of the molds allows the machine to produce straight, curved, or special-profile curbs.

This concrete curb forming machine integrates a screw feeding system and a high-frequency vibrator, ensuring the concrete is fully compacted and forms a durable, seamless structure.

Product Performance and Advantages

During testing, the YG20 Slipform Curb Machine for Sale showed excellent performance:

- Continuous Curb Forming: Works along pre-set routes, forming curbs seamlessly.

- High Efficiency: The machine can produce several meters of curbs per minute, saving significant time.

- Consistent Shape and Finish: Laser or wire guidance ensures perfect height and alignment.

- Durable Structure: On-site-formed curbs are stronger and more uniform than pre-cast pieces.

- Low Maintenance: Hydraulic drive system reduces mechanical wear and energy consumption.

Compared with manual pouring or pre-cast curb installation, the YG20 machine helped the client shorten project duration by nearly 40% while improving precision and aesthetics.

Production and Quality Control

All YG slipform machines are manufactured using high-strength alloy steel and precise welding technology. Each machine undergoes:

- Hydraulic pressure test – to ensure stable power output;

- Blade and mold alignment test – to guarantee forming accuracy;

- Full operational inspection – before packing and shipment.

YG also ensures that every machine meets South African import standards, including voltage compatibility, hydraulic fittings, and safety certifications. This gives customers full confidence in using the machine upon arrival.

Delivery and Export Process

After confirming the order, YG completed the entire production and inspection process within 15 working days.

Export Process Overview:

- Contract signing and technical confirmation;

- Manufacturing and quality testing of the YG20 machine;

- Application of rust-preventive oil and wooden crate packaging;

- Sea shipment through Durban Port, South Africa;

- Delivery documentation, including invoice, manual, and test video.

YG’s logistics team provided real-time shipping updates and assisted with customs clearance, ensuring the customer received the machine smoothly and on time.

Customer Feedback and On-Site Performance

After installation, the South African client used the YG20 curb and gutter machine for a municipal road project. The customer praised:

“The machine works better than expected. It’s easy to operate and produces perfect curbs without cracks or deformation.”

Results from the project:

- Curb production speed increased by 45%.

- Material waste reduced by 20%.

- The finished curb surface was smoother and stronger than pre-cast types.

The client also shared photos and videos showing the machine’s performance on-site and confirmed plans to purchase another unit for highway drainage curb construction.

Why South African Customers Choose YG Machinery

YG Machinery has supplied slipform curb machines for sale to over 60 countries, including South Africa, Kenya, Egypt, and Saudi Arabia. Customers prefer YG for several reasons:

- Rich experience: Over 15 years of manufacturing slipform and concrete machinery.

- Custom solutions: Support for different curb sizes, molds, and optional attachments.

- High reliability: Durable structure and easy operation, suitable for all job sites.

- Global service: OEM support, spare parts supply, and 24/7 online technical guidance.

YG continues to strengthen its presence in the African market by offering reliable equipment and full export support.

Contact YG today to get your customized Slipform Curb Machine for Sale — the perfect choice for efficient, durable, and precise concrete curb construction.

WhatsApp/WeChat/Phone: 86 138 3715 9132