Choosing the right piling equipment is not as simple as comparing prices or machine size. Many buyers struggle between a Hydraulic Pile Driver and an excavator pile driver because both can drive piles, but they work very differently on real job sites. The wrong choice can lead to low efficiency, high fuel cost, and even project delays. This guide explains the key differences, real applications, and decision factors to help you select the piling solution that truly fits your project needs.

What Is a Hydraulic Pile Driver and an Excavator Pile Driver

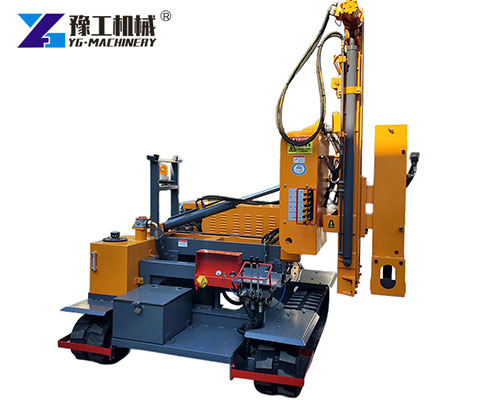

A Hydraulic Pile Driver is a standalone piling machine powered by a hydraulic system. It is designed only for pile driving work and is often used in road projects, solar farms, and foundation construction.

An Excavator Pile Driver is a pile driving attachment installed on an excavator. It uses the excavator’s hydraulic system to drive piles into the ground.

The key difference is simple:

- A Hydraulic Pile Driver is a complete machine

- An Excavator Pile Driver is an attachment that depends on an excavator

Understanding this difference is the first step to making the right choice.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Working Principle Comparison: Hydraulic Pile Driver VS Excavator Pile Driver

Although both machines use hydraulic power, their working logic is different.

A Hydraulic Pile Driver works with:

- An independent hydraulic system

- A stable piling frame or mast

- Optimized vertical control

This structure allows the machine to keep a stable force during continuous pile driving.

An excavator pile driver works by:

- Connecting to the excavator boom

- Using the excavator’s hydraulic output

- Adjusting pile position through boom movement

This gives higher flexibility but relies heavily on the excavator’s condition and the operator’s skill.

Application Scenarios: When to Choose Each Type

Applications of a Hydraulic Pile Driver

A Hydraulic Pile Driver is commonly used in projects that require high efficiency and consistency.

Typical applications include:

- Solar power plant construction

- Highway guardrail installation

- Large-scale foundation piling

- Long-term piling projects

In solar projects, a dedicated hydraulic pile driver can work continuously with stable speed and a lower error rate.

Applications of an Excavator Pile Driver

An Excavator Pile Driver is more suitable for flexible and smaller projects.

Common use cases include:

- Small construction sites

- Projects with frequent relocation

- Sites with complex terrain

- Contractors who already own excavators

For buyers with a limited budget or existing excavators, this option can reduce initial investment.

Cost and Investment Comparison for Buyers

Cost is often a key factor when choosing piling equipment.

For a Hydraulic Pile Driver, buyers should consider:

- Higher machine purchase cost

- Lower cost per pile in large projects

- Independent operation without extra equipment

For an excavator pile driver, buyers should consider:

- Lower attachment price

- Existing excavator availability

- Higher wear on the excavator hydraulic system

In short:

- Large projects → Hydraulic pile driver is more cost-efficient

- Small or mixed projects → Excavator pile driver is more flexible

Solar Projects: Which Pile Driving Solution Works Better

Solar farms have special requirements for piling work.

Key needs include:

- High piling speed

- Uniform pile depth

- Stable vertical alignment

A Hydraulic Pile Driver is often preferred for large solar farms because it can:

- Work for long hours

- Keep consistent piling quality

- Reduce operator fatigue

However, in small solar projects or rooftop systems, an excavator pile driver may still be a practical choice.

Key Factors to Consider Before Choosing a Hydraulic Pile Driver

Before making a final decision, buyers should clearly understand their real needs.

Important factors include:

- Project size and total pile quantity

- Soil condition (soft soil, clay, hard ground)

- Available equipment on site

- Local operator experience

- Project timeline

Choosing a Hydraulic Pile Driver only makes sense when the machine capacity matches the actual project scope.

Common Buyer Mistakes When Selecting Pile Driving Equipment

Many buyers make similar mistakes during equipment selection.

Common mistakes include:

- Choosing based on price only

- Ignoring soil condition differences

- Using an excavator pile driver for heavy-duty projects

- Overestimating project scale

These mistakes often lead to low efficiency and higher long-term costs.

Final Advice: How to Choose the Right Pile Driving Solution

If your project involves:

- Large-scale solar farms

- Long-term piling work

- High efficiency requirements

A Hydraulic Pile Driver is usually the better solution.

If your project involves:

- Small or short-term jobs

- Limited budget

- Existing excavators

An excavator pile driver may be enough.

The right choice is not about which machine is better, but which one fits your project better.

WhatsApp/WeChat/Phone: 86 138 3715 9132