On modern construction sites, steel bars are rarely used in their original form. Before installation, rebar usually needs to be straightened, cut, bent, or shaped to match structural drawings. This is why different types of rebar machines are commonly seen on construction sites.

Understanding what each machine does, and when it is actually needed, helps buyers avoid over-investment and choose equipment that truly fits the project stage. This article explains the most common types of rebar machines used on construction sites and how they support daily work.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Why Construction Sites Use Different Types of Rebar Machines

Construction projects handle rebar in many forms and sizes. Some projects use coiled steel bars, while others work mainly with straight bars. Some require simple cutting, while others need precise bending or repeated stirrup shapes.

Using the right machine brings several clear benefits:

- Faster processing compared to manual work

- More consistent rebar size and shape

- Lower labor intensity on-site

- Better control of construction quality

For this reason, different types of rebar machines are used depending on project scale, rebar form, and processing requirements.

Rebar Straightening Machines For Coiled Steel Bars

Coiled rebar is popular because it saves transport space and is easier to store. However, it cannot be used directly in construction. A rebar straightening machine is used to remove internal stress and make the steel bar straight before further processing.

These machines are commonly used on construction sites that:

- Receive rebar in coil form

- Process small to medium bar diameters

- Need flexible, on-site preparation

In many projects, straightening is the first step before cutting or bending, making this type of machine a practical choice for site-based work.

Straightening And Cutting Machines In Daily Site Work

In daily construction work, straightening and cutting are often done together. A straightening and cutting machine combines both steps into one continuous process.

This type of equipment is widely used because it:

- Saves time by combining two operations

- Produces bars with fixed, repeatable lengths

- Reduces manual measurement errors

For many contractors, the steel bar straightening cutting machine offers a good balance between efficiency and investment cost, especially on medium-sized projects.

Rebar Cutting Machines For Fixed-Length Bars

When the rebar is already straight, cutting becomes the main task. A rebar cutting machine is designed to cut steel bars to the required lengths quickly and cleanly.

On construction sites, cutting machines are mainly used for:

- Preparing bars for bending or threading

- Handling thicker bar diameters

- Reducing manual cutting labor

Hydraulic cutting machines are especially common due to their stable performance and simple operation, making them suitable for both temporary and long-term site use.

Rebar Bending Machines For Common Shape Forming

A rebar bending machine is used to bend straight steel bars into angles or simple shapes according to structural design. This is one of the most frequently used machines on construction sites.

Typical bending tasks include:

- L-shaped and U-shaped bars

- Standard angle bending

- Simple frame structures

On-site bending allows workers to adjust shapes quickly when drawings change, which is why bending machines remain essential even when some rebar is pre-processed off-site.

Stirrup Bending Machines For Repetitive Rebar Shapes

Stirrups are small, repetitive rebar shapes used in beams, columns, and foundations. Producing them manually is slow and inconsistent. A stirrup bending machine is designed specifically for this task.

These machines are often used when:

- Large quantities of identical stirrups are required

- Consistent size and angles are critical

- Labor efficiency needs to be improved

Automatic stirrup bending machines are common on projects with high rebar volume, such as residential buildings and infrastructure works.

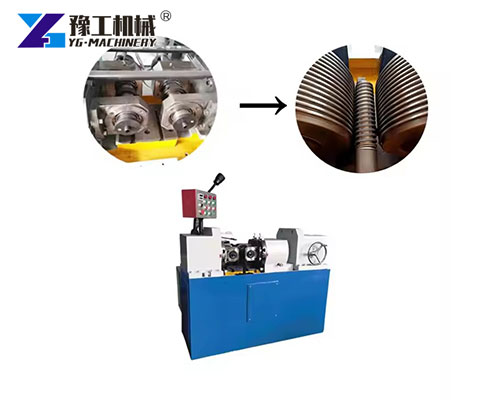

Thread Rolling Machines For Mechanical Rebar Connections

Mechanical connections are increasingly used instead of welding or lap joints. A thread rolling machine creates threads on rebar ends so they can be connected using couplers.

This method is popular because it:

- Provides strong and reliable connections

- Reduces steel waste from overlapping

- Improves connection consistency

Thread rolling machines are often seen on projects with strict structural standards, especially in high-rise buildings and large infrastructure construction.

Curving Machines For Special Structural Requirements

Some construction projects involve circular or curved structures, such as bridges, tunnels, or round foundations. In these cases, standard bending machines are not enough.

Rebar curving machines are used when:

- Large-radius curves are required

- Precision forming is important

- Rebar shapes are non-standard

These machines are not used on every site, but they play an important role in projects with special structural designs.

When Certain Rebar Machines Are Not Necessary

Not every construction site needs all the rebar machines. In fact, using too many machines can increase cost and reduce efficiency.

For example:

- Small projects may not need automatic stirrup machines

- Short-term sites may rely on manual cutting instead of hydraulic cutters

- Pre-fabricated rebar supply can reduce on-site processing needs

Understanding project scale and workflow helps buyers avoid unnecessary equipment investment.

Common Questions Buyers Ask Before Choosing Rebar Machines

Do all construction sites need the same rebar machines?

No. Equipment choice depends on rebar form, project size, and processing volume.

Is on-site processing always better than factory processing?

Not always. Many projects use a mix of factory-prepared and on-site processed rebar.

Which rebar machine is usually purchased first?

Straightening, cutting, and bending machines are often the starting point.

Are automatic machines always better?

Automatic machines improve efficiency, but manual or semi-automatic machines may be more suitable for small or flexible projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132