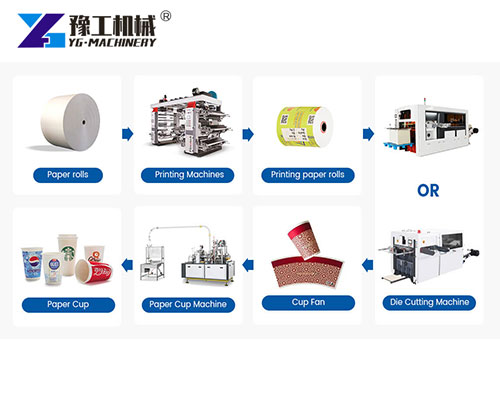

A UK customer ordered a coffee cup making machine, along with a matching coffee cup printing machine, from YG Machinery. The goods were shipped, delivered, and installed, and the customer has already started stable production.

At the start of this project, the Coffee Cup Making Machine was chosen as the core of the line because it offers fast forming speed, low defect rate, and easy operation. Pairing it with a high-precision printer allowed the customer to build a compact, flexible plant for branded cups.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Customer Background And Buying Journey

The client is based in the UK and runs a coffee chain while also supplying disposable paper cups to local cafés. Their goals were clear:

- Cut the cost of buying finished cups from third parties.

- Print their own brand logo to strengthen store identity.

- Find cost-effective, reliable equipment with quick setup.

The purchasing manager searched Google for “coffee cup making machine price” to compare offers and technical details. Our case studies, lead time, and after-sales plan matched their needs, so they requested a detailed proposal and a remote demo. After conducting sample tests and a brief price review, they confirmed the order for a combined coffee cup-making machine and coffee cup printing machine package.

Product Parameters of Coffee Cup Making Machine

| Model | YG-35 |

| Paper Cup Size | 3-16oz |

| Paper Cup Top Diameter | Min 65mm-max94mm |

| Paper Cup Bottom Diameter | Min45mm-60mm |

| Paper Cup Height | Min60mm-135mm |

| Raw Material | PE-COATED PAPER.RIPPLE PAPER ETC |

| Speed | 80-90pcs/min |

| Speed of 20 hours of stable running per day | |

| Suitable paper weight | 150-350gsm |

| Voltage supply | 220v50hz single phase/ 380v50hz 3-phase(better to use 380v50hz 3-phase)*If the user’s voltage supply is different, please inform us in advance. |

| General power | 4.7KW |

| Net weight | 1500kgs |

| Measurement (mm) | 2150*950*1650MM |

| Cup Side Sealing | Ultrasonic |

| We can customize the machine and mold according to the customer’s requirements. | |

Product Parameters of Printing Machine

| Model | YG-320 | YG-420 | YG-550 | YG-650 |

| Max. web width | 320 mm | 420 mm | 550 mm | 650 mm |

| Max. printing width | 310 mm | 410 mm | 520 mm | 650 mm |

| Printing speed | 10-60 m/min | 10-60 m/min | 10-60 m/min | 10-60 m/min |

| Printing color | 1/2/3/4/5/6/7/8 color | 1/2/3/4/5/6/7/8 color | 1/2/3/4/5/6/7/8 color | 1/2/3/4/5/6/7/8 color |

| Max. unwinding diameter | 600 mm | 600 mm | 600 mm | 600 mm |

| Max. rewinding diameter | 600 mm | 600 mm | 600 mm | 600 mm |

| Printing length | 177.8-355.6 mm | 177.8-355.6 mm | 177.8-355.6 mm | 177.8-355.6 mm |

| Voltage | 380V±10% | 380V±10% | 380V±10% | 380V±10% |

| Precision | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| Voltage | 3P 380V,50HZ | 3P 380V,50HZ | 3P 380V,50HZ | 3P 380V,50HZ |

Both machines were tested before shipment. The package included spare parts, tools, and English manuals to speed up ramp-up.

Paper Cup Forming Machine Price: Key Factors

The paper cup forming machine price depends on:

- Production Speed: higher speed requires stronger frames, better drives.

- Automation Level: auto lubrication, camera inspection, and servo axes add value.

- Paper and Cup Range: a wider range needs extra tooling and heating options.

- Build Quality: materials, bearings, heaters, and control brand selection.

- After-Sales Package: training, spare parts, and remote diagnostics.

Compared With Many UK-market options

- Lower total cost for the same output class.

- Strong energy efficiency and fewer consumables.

- Quick parts supply plan and remote service reduce downtime.

The customer chose our solution because the Coffee Cup Making Machine offered a balanced paper cup forming machine price with higher output and clear upgrade paths.

Export And Delivery To The UK

We followed a clear project timeline to reduce risk and speed up start-up:

- Order & Pre-Production: confirm specs (cup sizes, paper type, print colors).

- FAT Testing: factory acceptance test with live video and sample packs.

- Packaging & Container Loading: anti-rust treatment, shock-proof crates, labels.

- Sea Freight To UK Port: shipping documents, HS codes, and insurance included.

- Customs & Delivery: support for import procedures via a broker.

- Remote Installation & Training: step-by-step guidance, video calls, and checklists.

- Trial Production: print test, die-cut samples, form, leak check, and packing.

By the end of week one after arrival, the line completed a full pilot run of branded 8-oz and 12-oz cups.

Coffee Cup Printing Machine: Quality Results In The UK Plant

After start-up, the customer ran daily batches with two brand designs. Color density and logo edges met their marketing standards. The coffee cup printing machine was delivered:

- Clean registration on curved surfaces.

- Consistent color from morning to evening runs.

- Fast switch between seasonal designs with saved presets.

Customer Feedback From the UK

Production started quickly and returned a stable yield. Reported benefits:

- High Product Quality: round shape, tight seams, and clean prints.

- Lower Procurement Cost: In-house production replaced external suppliers.

- Brand Power: flexible designs for campaigns and store openings.

- Confidence To Scale: clear plan to add a second Coffee Cup Making Machine when monthly demand increases.

They expressed intent for long-term cooperation and asked for quotes on automatic case packing to extend the paper cup production line.

Why Choose Our Coffee Cup Making Machine

- Proven Manufacturing Experience: many export cases and stable core components.

- Matched Packages: Automatic Paper Cup Machine, Coffee Cup Printing Machine delivered as a tuned set.

- High Cost Performance: suitable for small factories and mass producers.

- Complete After-Sales: remote training, spare parts plan, and fast response.

- Scalable: add leak test, inspection camera, or auto packer as demand grows.

This UK case shows how a combined Coffee Cup Making Machine and coffee cup printing machine can cut costs and lift brand value at the same time. Ready to plan your line? Contact us now to get a clear coffee cup-making machine price, layout advice, and a tailored solution for your factory. We can also size a full paper cup production line for your target capacity and budget.

WhatsApp/WeChat/Phone: 86 138 3715 9132