A Yemeni customer ordered a Core Drilling Machine for Sale. The unit was delivered, installed, and is now in daily use. The team reports high drilling speed and stable cores that meet project needs.

Customer Background And Purchase Process

The client works in infrastructure construction. They handle roads, bridge repairs, and public buildings. Their labs also test material samples from job sites. They needed a machine that could drill concrete for quality checks and also take rock cores for foundation evaluation.

The buyer searched on Google using phrases like “core drilling machine for sale” and landed on YG’s product page. After sending an inquiry, our product manager called to learn more:

- What core diameters and depths were required?

- What power supply is available on site?

- How soon is delivery needed?

Based on the answers, we proposed a compact stand-type core drill for concrete and asphalt, plus a portable rig package for shallow rock coring. We showed torque curves, speed ranges, and real project photos. We also explained drill bit selection and water management. After a short technical review on video call, the client confirmed the order.

Core Drilling Rig Machine — Project Requirements In Yemen

The Core Drilling Rig Machine had to meet mixed tasks:

- Take concrete cores from bridges, tunnels, and slabs.

- Drill asphalt layers on roads for lab tests.

- Extract shallow rock cores near foundations and slopes.

- Work in hot, dusty conditions with stable performance.

- Move quickly between urban and remote sites.

To match these needs, we configured a robust base, a high-torque motor, a three-speed gearbox, and wet drilling accessories. This solution kept the machine steady and cool during long runs.

Technical Specifications of the Core Drilling Machine for Sale

Below are representative specs of the supplied configuration. Values can be customized.

| Model | YG-400XL | YG-600S/GL | YG-800S/GL | YG-1000GL |

| Drilling depth | 180-400-500m | 200-600-650m | 400-800-1000m | 500-1000-1100m |

| Drilling angle | 0~90° | 45~90° | 45~90° | 45~90° |

| Max. Torque | 500N.m | 1000N.m | 1300N.m | 3500N.m |

| Rated power/speed | 78kW/ 2400r/min | 92kW/ 2400r/min | 92kW/ 2400r/min | 154kW/ 2400r/min |

| Hydraulic Mud pump flow | 30-90(L/min) | 30-90(L/min) | 90-180(L/min) | 90-180(L/min) |

| Hydraulic Mud pump power | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) |

| Walking speed | 2.5 km/h | 3.5 km/h | 3.5 km/h | 3.5 km/h |

| Climbing angle | Max. 45° | Max. 45° | Max. 45° | Max. 45° |

| Transport Dimension | 4000*1900*1800mm | 4000*2000*1800mm | 5500*2100*2000mm | 6000*2200*2400mm |

| Weight | 4.3T | 4.5/5.5T | 6.5T | 7.5T |

These specifications enable the Core Drilling Machine for Sale to handle both laboratory sampling and on-site coring, producing clean, full-length cores.

Product Features of Core Drilling Rig Machine

Key benefits reported by the customer after deployment:

- High Drilling Efficiency — fast penetration in concrete and rock.

- Durable Bits — wear-resistant segments extend service life.

- Versatile Use — suitable for lab benches and job sites.

- Stable and Safe — rigid column, reliable clamps, emergency stop.

- Easy Setup — quick anchor or vacuum base, simple water line.

- Low Maintenance — accessible gearbox, replaceable seals and bearings.

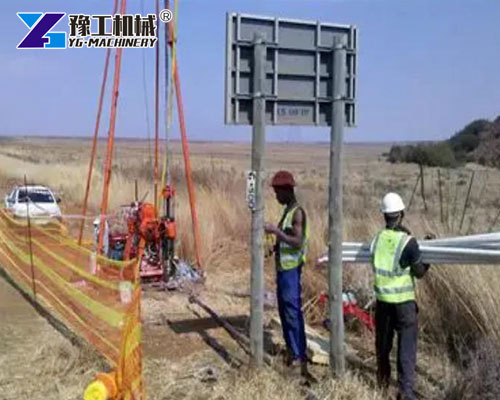

Delivery And Setup

- Shipping Method: Container sea freight to a Yemen port, then local trucking to the contractor’s yard.

- Packaging & Protection: Reinforced wooden crates, anti-shock padding, moisture barrier film, and labeled tool cases for barrels and bits.

- Arrival & Start-Up: YG engineers provided remote guidance for assembly, water connection, and first test runs. We verified rpm, feed rate, and core extraction steps on a live video call.

The machine passed acceptance in a single session and began operation the same week.

Customer Feedback

After several weeks, the client shared direct results:

- Higher Output: More cores per shift than their old unit.

- Clean Cores: Edges stayed intact, even with rebar present.

- Easy Moves: Wheel base rolled well across the site; track carriage handled rough areas.

- Low Downtime: Routine checks were quick; spare segments and seals were easy to swap.

- Operator Confidence: Clear gauges and overload protection reduced mistakes.

They confirmed the package met the original plan for concrete and rock sampling and plan to add more barrels in larger diameters.

Why Choose YG Machinery

- Proven Export Capability: Reliable packing, clear documents, and on-time shipping for international jobs.

- Customized Solutions: Diameter, depth, power, and base type tailored to your site.

- Parts and Service: Stocked consumables, fast technical responses, and remote training.

- High Value: Strong performance and fair price for global contractors.

- Application Support: Bit selection guides, rpm/gear charts, and water management tips.

These strengths help teams in challenging environments stay on schedule and within budget.

Request A Quote for a Core Drilling Machine

Need a Core Drilling Machine for Sale for concrete, asphalt, or shallow rock? Send your target core diameters, depth per hole, power source, and site photos. Our engineers will match the right drive, gearbox, and bit set, then provide a clear price and delivery plan—so your project in Yemen can start faster with reliable, tested equipment.

WhatsApp/WeChat/Phone: 86 138 3715 9132