A customer in Nigeria ordered a Tank Cleaning Robot For Sale from YG Machinery and started using it as soon as it arrived.

Project Background: Nigeria Refinery Needed A No-Entry Tank Cleaning Solution

A large refinery in Nigeria had a crude oil storage tank filled with heavy and sticky sludge. Manual cleaning was risky due to toxic gases and flammable residue. The customer wanted a no-entry tank cleaning solution that would protect workers and improve cleaning speed.

The requirements included:

- Strong sludge removal ability

- Remote operation from a safe distance

- Explosion-proof system for refinery conditions

This job needed reliable equipment that could work inside a dark and harsh environment.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Industrial Tank Cleaning Robot Recommended For The Nigeria Project

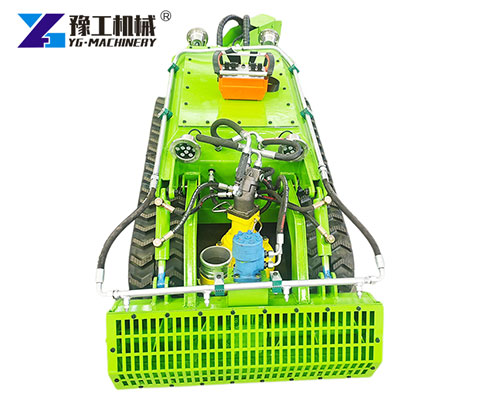

To meet the customer’s needs, we recommended our industrial tank cleaning robot, supported by essential auxiliary tools. This system matched the tank conditions and safety requirements.

Why This Robot Was Recommended

- High-pressure cleaning module to remove thick sludge

- Crawler chassis designed for deep, sticky, and uneven sediment

- HD camera system for dark tank environments

- Long working hours in harsh refinery conditions

Auxiliary Equipment

- Suction pump

- Sludge transfer pipe system

- Remote control station

These tools helped the system work smoothly from setup to final cleaning.

Robotic Tank Cleaning Machine Delivery And Installation In Nigeria

The customer selected the equipment quickly after watching cleaning test videos. We prepared the robot for export with strict quality checks.

The system shipped in a wooden crate, along with all necessary export documents. After arrival in Lagos, the customer completed installation with online guidance from our engineers.

During training, operators learned:

- How to start and control the robot

- How to monitor cleaning through the camera system

- How to maintain the robotic tank cleaning machine

The customer team mastered operation after a short training session.

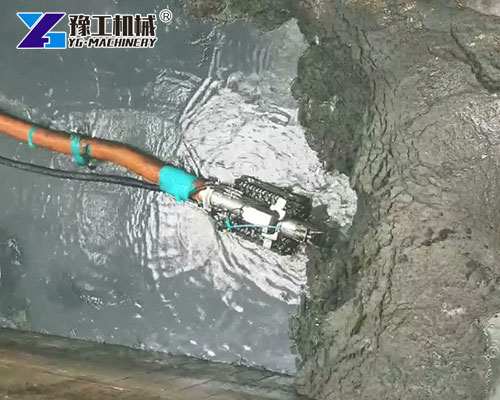

Oil Tank Cleaning Robot Performance In The Nigeria Refinery

Once the job began, the robot delivered strong and stable cleaning results. The local team tested the equipment in heavy sludge and confirmed that the oil tank cleaning robot met all expectations.

Cleaning Results

- Removed over 85% of heavy sludge in the first 2 days

- Total cleaning time: 5 days, compared to 15–20 days with manual work

Safety And Cost Benefits

- No workers entered the tank

- Reduced labor costs and stopped downtime

- Real-time video monitoring ensured stable cleaning quality

The refinery was able to resume operation earlier and reduce cleaning expenses.

Customer Feedback From The Nigeria Refinery Project

The Nigerian customer shared positive feedback after completing the project. They noted several clear advantages:

- The robot moved smoothly even in very thick sludge

- Cleaning speed was faster than they expected

- The operation was easy after simple training

- Strong suction and washing power made the tank meet inspection standards

Because of the successful cleaning results, the refinery decided to order another Tank Cleaning Robot For Sale for a second storage tank.

YG Tank Cleaning Robot Advantages For Global Projects

Our robot is widely used in oil tanks, chemical tanks, and sludge tanks in many countries. It is designed to work in harsh environments and provide a safe and stable cleaning process.

Key Advantages

- Excellent performance in heavy sludge tanks

- Reliable no-entry tank cleaning solution

- Strong crawler structure for sticky and uneven sediment

- Global delivery and technical support

- Custom upgrades for different tank types and conditions

These benefits make the system suitable for international refinery, chemical plant, and wastewater plant applications.

WhatsApp/WeChat/Phone: 86 138 3715 9132