A Saudi customer ordered a tracked scissor lift from YG Machinery, received the machine, and is very satisfied with its stable performance and easy maintenance.

Customer Background and Purchase Process

A Saudi construction firm needed a machine for hard ground and sand. Their industry is building and infrastructure. They wanted a lift that works in the desert and on rough sites. The buying steps were simple and clear:

- The customer sent project details and asked for a quote.

- YG replied with options and technical drawings.

- The customer chose the tracked model with diesel power.

- Contract, payment, and factory production were arranged.

- The machine was shipped and arrived at the Saudi site.

They chose Chinese equipment for good reasons. The price was competitive. Quality met international standards. Custom options were available. YG offered local-style training and after-sales support. This mix of cost, quality, and service made the purchase strong.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Tracked Scissor Lift for Sale In Saudi Arabia

The Tracked Scissor Lift For Sale model from YG suits uneven and sandy land. It is built for safe high work. The platform lifts workers and tools to the needed height. The tracked chassis gives extra grip. This model is easy to move on soft ground. It is a good choice for remote and open sites.

Technical Specifications of Tracked Scissor Lift for Sale

| Model | Up(m) | Load(kg) | Platform size(m) | Outline dimensions/guardrail folding(m) | Lifting motor | Weight(kg) |

| YG0608SP | 5.8 | 230 | 1.67*0.74 | 1.86*0.76*1.84 | 24v/3.3kw | 1580 |

| YG0608 | 6 | 450 | 2.27*1.12 | 2.48*1.19*1.66 | 24v/3.3kw | 2170 |

| YG0810NP | 8 | 230 | 2.27*0.81 | 2.48*0.83*1.99 | 24v/3.3kw | 2260 |

| YG0810 | 8 | 450 | 2.27*1.12 | 2.48*1.19*1.78 | 24v/3.3kw | 2360 |

| YG1012 | 10 | 320 | 2.27*1.12 | 2.48*1.19*1.91 | 24v/3.3kw | 2640 |

| YG1214 | 11.8 | 320 | 2.27*1.12 | 2.48*1.19*2.03 | 24v/4.5kw | 2980 |

| YG1416 | 13.7 | 230 | 2.64*1.12 | 2.85*1.25*2.105 | 24v/4.5kw | 3600 |

All-Terrain Scissor Lift Application Scenarios

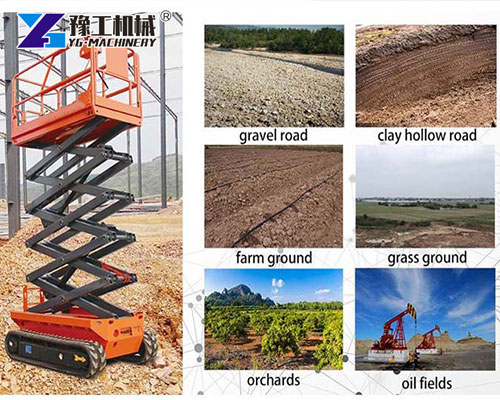

All-Terrain Scissor Lifts fit many places. The tracked base is for rough ground and soft sand. Common uses include:

- Construction sites on desert land or loose soil.

- Outdoor maintenance for roofs, lights, or signs.

- Factories and yards with gravel or uneven floors.

- Warehouses where rough outdoor access is needed.

In Saudi Arabia, the All-Terrain Scissor Lift helps teams reach high points even on dunes. The tracks reduce sink risk. The lift can also work with other machines on big projects.

Hydraulic Scissor Lift Platform Features

The Hydraulic Scissor Lift Platform is made for strength and safety. Key features include:

- All-terrain tracked chassis for sand, mud, and rocks.

- High-capacity platform for several workers or heavy tools.

- A stable hydraulic system to keep balance on slopes.

- Safety devices: guardrails, anti-tip, and emergency descent.

- Multiple power choices: diesel, electric, or hybrid.

- Compact body for easy transport and storage.

These features make the lift reliable. The hydraulic system runs smoothly. Operators can work safely at height in tough conditions.

Mobile Elevated Work Platform Advantages

A Mobile Elevated Work Platform brings clear business benefits. The tracked design allows safe moves on soft ground. Other advantages are:

- Fast deployment on many sites.

- Better access where wheels would fail.

- Works without external power when a diesel engine is used.

- Easy to position near walls, poles, and frames.

The Mobile Elevated Work Platform helps teams finish tasks faster. Local crews noted the ease of use and stable lifting.

Customer Feedback And Onsite Experience

After delivery, the Saudi team tested the machine. Feedback focused on stability, power, and service:

- Stable Performance: The tracked base stayed steady on sand.

- Strong Climbing: The lift climbed slopes with a load.

- Easy Maintenance: Parts are simple to reach and change.

- Operator Praise: Local workers found controls easy to learn.

- Cost Advantage: Compared with local machines, YG offered better prices and spare parts access.

One project manager said the lift reduced time to reach high points by 30%. This led to faster daily progress and lower labor costs.

How The Tracked Design Helps In Desert Work

Tracks spread the machine’s weight across more ground. This lowers the chance of sinking. In desert or soft soil, this matters most. The tracked lift moves more easily than wheeled models. Diesel power gives long run time at remote sites. The hydraulic system keeps the platform steady during windy days.

Ordering, Delivery, And After-Sales Support

Ordering a Tracked Scissor Lift for Sale is simple. Steps are:

- Send your site and load details to YG.

- Get a tailored quote and machine drawing.

- Confirm order and finish payment terms.

- The factory makes the machine and runs tests.

- Ship to Saudi Arabia with paperwork and customs help.

YG gives training for local operators. Spare parts and manuals are supplied. Remote technical help is available. This after-sales plan keeps machines running longer.

YG Manufacturer’s Other Elevated Work Platforms

YG also makes a wide range of lifts to suit different jobs:

- Electric Scissor Lifts for indoor use.

- Mobile Scissor Lifts for quick site moves.

- Mast Lifts.

- Telescopic Boom Platforms.

- Fully Automatic Wheeled Elevators.

- Small Scissor Lifts for narrow jobs.

- Cherry Picker Style Harvesting Arms.

- Truck-Mounted Scissor Lifts for road work.

These models can support mixed fleets on large projects. YG can help choose the right mix for your needs.

WhatsApp/WeChat/Phone: 86 138 3715 9132