The cold plastic road marking machine is a versatile piece of equipment designed to apply durable road markings using solvent-based or water-based cold plastic materials. Unlike thermoplastic machines, cold plastic systems require no heating, making them ideal for low-temperature environments or projects requiring quick deployment. These machines are widely used for creating traffic lines, crosswalks, and safety symbols on various pavement surfaces, offering high visibility and longevity.

Contact us via WhatsApp/WeChat at +86 138 3715 9132

Cold Plastic Road Marking Machine Parameters

| Model | YG-8S | YG-8D |

| Power | 5.5HP | 5.5HP |

| Plunger Pump | Electronic Commutation | Automatic Reciprocating Reversion |

| Spray Gun Quantity | Single Gun | Two Guns |

| Operation Mode | Hydraulic Drive | Hydraulic Drive |

| Work Pressure | 8-12MPa | 8-12MPa |

| Flow Of Spray | 4.8L/min | 8L/min |

| Width Of Spray | 100-300mm | 100-450mm |

| Thickness Of Spray | 0.2-0.4mm | 0.2-0.4mm |

| Dimension | 1600mm*800mm*1200mm | 1600mm*800mm*1200mm |

| Weight | 120kg | 120kg |

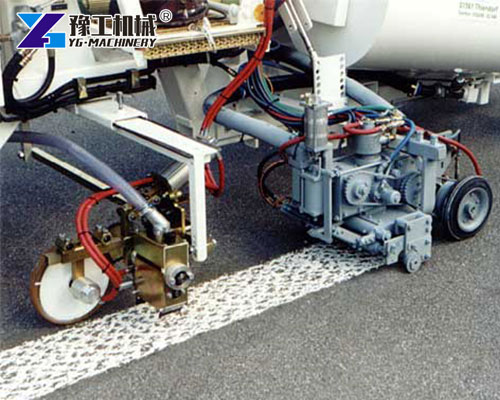

Key Components of a Cold Plastic Marking Machine

- Paint Tank: Holds the cold plastic material (liquid or paste) and may include agitation systems to prevent settling.

- Spray Nozzle/Applicator: Distributes the material evenly, with adjustable widths (50–400mm) for different line types.

- Control Panel: Manages application speed, pressure, and optional features like glass bead dispensing.

- Glass Bead Dispenser: Integrates reflective beads into the wet marking for enhanced night visibility.

- Mobility System: Wheeled or truck-mounted designs for easy transport between job sites.

How Cold Plastic Road Marking Machines Work

- Surface Preparation: Clean the road to remove debris and ensure adhesion. Prime porous surfaces if necessary.

- Material Mixing: Stir the cold plastic material to achieve uniform consistency (no heating required).

- Application: Spray or roll the material onto the surface using the machine’s nozzle or applicator, following pre-marked guidelines.

- Bead Dispensing: Automatically sprinkle reflective glass beads over the wet marking.

- Curing: Dries in 5–15 minutes, depending on weather, creating a hard, durable finish ready for traffic.

Features of Road Marking Machine for Cold Plastic

- No Heating Required: Operates at ambient temperatures, saving energy and reducing setup time.

- Adjustable Width: Customize line thickness (1–3mm) and width (50–400mm) for diverse marking needs.

- Portable Design: Lightweight models for small projects; heavy-duty, truck-mounted systems for large-scale use.

- Automatic Bead Integration: Ensures consistent reflectivity without manual labor.

Advantages of Cold Plastic Road Marking Machines

Durability

Cold plastic markings resist abrasion, UV rays, and weathering, lasting 2–3 years in high-traffic areas—ideal for urban roads and highways.

High Visibility

Reflective glass beads enhance visibility in low light, reducing accident risks in dawn/dusk or rainy conditions.

Fast Application

Dries rapidly (5–15 minutes), minimizing road closures and disrupting traffic flow.

Eco-Friendly

Water-based formulations are low-VOC, compliant with EU environmental standards, and safe for urban environments.

Long-Term Cost-Effective

Lower upfront costs than thermoplastic systems, plus reduced labor and energy expenses.

How to Use Cold Plastic Road Marking Machines

- Training: Operators should receive guidance on material mixing, nozzle adjustment, and safety protocols.

- Maintenance: Clean nozzles and tanks after use to prevent material buildup.

- Storage: Store in dry conditions to protect components from corrosion.

Applications of Cold Plastic Road Marking Machines

Infrastructure Projects

- Highways: Lane dividers, speed limit symbols, and emergency stop lines.

- Urban Streets: Crosswalks, bike lanes, and parking lot markings.

- Rural Roads: Warning signs and wildlife crossing indicators.

Climate Adaptability

- Performs in temperatures as low as 0°C, making it suitable for northern climates.

- Resists cracking in cold weather and softening in heat.

Safety Enhancement

Reflective properties improve pedestrian and driver awareness, particularly in school zones and low-light areas.

Choosing the Right Cold Plastic Road Marking Machine

Key Factors

- Small/Medium Project Scale: Portable, manual machines (e.g., 50–100L tanks) for parking lots or sidewalks.

- Large Project Scale: Truck-mounted, automated systems with GPS guidance for highways.

- Features Needed: Prioritize bead dispensers, adjustable pressure, or anti-clog nozzles based on project demands.

ROI Considerations

While cold plastic machines offer lower initial costs, prioritize durability and maintenance needs for long-term savings.

YG Cold plastic road marking machine for sale

YG Cold plastic road marking machines are a valuable addition to the road maintenance and construction industry, offering a reliable, durable, and environmentally friendly solution for creating high-visibility road markings. Whether you’re looking to enhance road safety on highways, city streets, or pedestrian areas, Cold Plastic machines provide an efficient and cost-effective way to get the job done. Contact us via WhatsApp/WeChat at +86 138 3715 9132