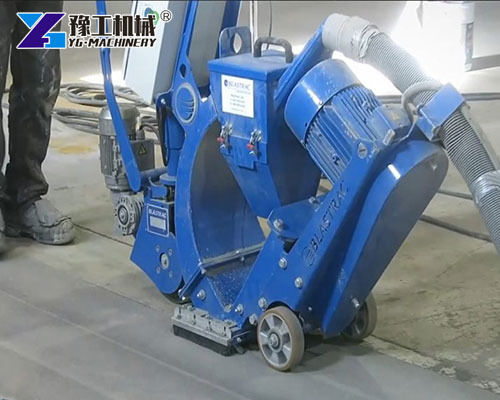

Concrete floor shot blasting is a mechanical surface preparation technique that uses steel abrasive (called shot) to clean and texture concrete surfaces. The process involves propelling the shot at high speed onto the floor using a dedicated floor shot blasting machine. The impact removes contaminants like paint, epoxy, or grime, while also creating a textured profile for improved bonding of new coatings or materials.

This method is highly valued in industrial, commercial, and renovation projects for its speed, efficiency, and eco-friendliness—no chemicals, no water, and minimal dust when paired with a proper vacuum system. WhatsApp/WeChat/Phone: 86 138 3715 9132

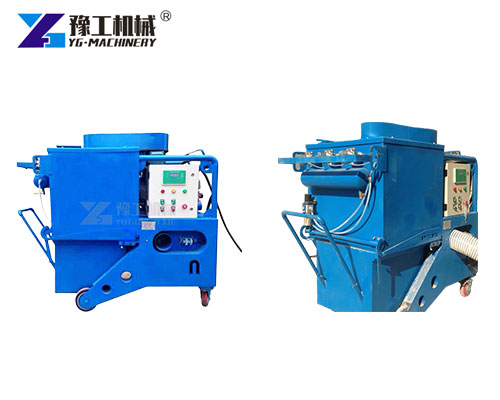

Concrete Floor Shot Blasting for Sale Parameters:

| Model | YG550/600(Double) | YG-850(Double) | |

| Shot Blasting Wheel Diameter | 200 mm | ||

| Working width | 550/600 mm | 800 mm | |

| Walking speed | 0.5~33 m/min | ||

| Concrete surface cleaning efficiency | ≥400 m2/h | ≥600 m2/h | |

| Steel plate surface cleaning efficiency | 75-100 m2/h | 100-160 m2/h | |

| Dust connection pipe diameter | 150 mm | ||

| Suggest the diameter of steel balls | 1.5-1.8 mm | ||

| Steel pill consumption | 10 g/m2 | ||

| Supporting dust collector | Eight-core automatic backflush vacuum cleaner | ||

| Shot wheel motor | Power consumption | 11*2 kW | 15*2 kW |

| Input Current | ≤ 22*2 A | ≤ 28*2 A | |

| Walking motor | Power consumption | 1.5 kW | |

| Input Current | 3 A | ||

| Size (mm) | 1950*720/775*1400 | 1950*1020*1550 | |

| Weight | 570 kg | 700kg | |

| Power connection requirements | 400V, 50Hz, 100A, CEE socket | ||

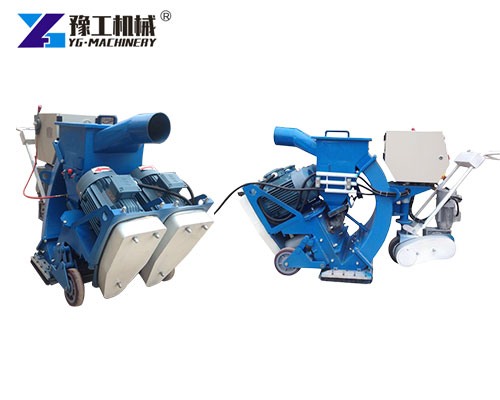

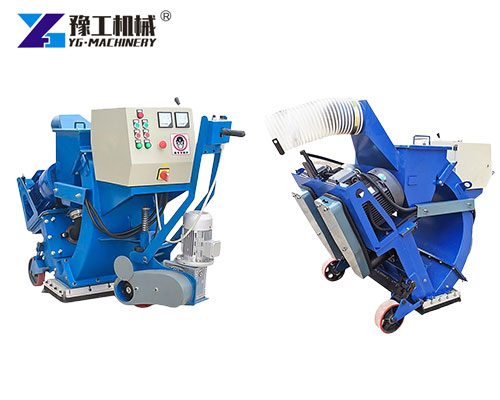

Basic Components of a Floor Shot Blasting Machine

A modern floor shot blasting machine includes several key parts that work together to deliver effective results:

- Blast Wheel: Spins at high speed to propel steel shot at the surface.

- Shot Hopper: Feeds the steel abrasive into the blast wheel.

- Vacuum System: Collects dust and debris, keeping the process clean and safe.

- Recovery System: Recycles usable shot and separates out broken particles.

- Control Panel: Adjusts blasting pressure, shot flow, and machine movement.

These components ensure the machine delivers consistent and controlled blasting for all types of concrete floors.

How Shot Blasting Works (Step-by-Step)

- Steel Shot Propelled at High Speed

A shot blasting machine uses a rapidly spinning wheel (called a blast wheel) to fling thousands of tiny steel balls (called “shot”) at the concrete surface at high velocity. - Surface Impact and Cleaning

The impact of the shot:- Dislodges dirt, coatings, rust, and surface laitance

- Roughens the surface to create a profile for better adhesion of coatings or overlays

- Vacuum Recovery System

After impact, a built-in vacuum system:- Recovers the spent shot and debris

- Separates reusable shot from waste

- Recirculates a clean shot back into the blasting process

Key Applications of a Concrete Shot Blaster

1. Surface Preparation for Coatings

- Epoxy flooring

- Polyurethane sealers

- Self-leveling compounds

Shot blasting creates a proper surface profile (e.g., CSP 3–5) to ensure strong adhesion of coatings and reduce failure risk.

2. Removing Surface Contaminants

- Old paint, adhesives, or sealants

- Grease, oil stains, or efflorescence

Shot blasting efficiently strips these materials without chemicals or grinding dust.

3. Polished Concrete Prep

- Before polishing, shot blasting can remove the top layer or previous coatings, exposing clean substrate for grinding and finishing.

4. Creating Slip-Resistant Surfaces

- Texturing smooth concrete to improve traction

- Used in warehouses, parking garages, loading docks, and wet environments

5. Bridge and Road Surface Prep

- Cleaning and profiling bridge decks or road surfaces for waterproofing membranes or overlays

- Removes laitance and prepares for anti-skid treatments

6. Airport Runways and Taxiways

- Restoring traction on worn surfaces

- Cleaning rubber buildup from airplane tires

7. Industrial Plant Maintenance

- Degreasing and resurfacing floors in factories and refineries

- Prepping concrete for repainting or anti-corrosive coatings

8. Decorative Concrete Projects

- Exposing aggregate in stamped or decorative concrete

- Creating contrast or non-slip finishes for design features

Advantages of Concrete Floor Shot Blasting

Using a concrete floor shot blasting system offers multiple operational and economic benefits:

- Eco-Friendly: No water or harsh chemicals needed.

- Fast and Efficient: Prepares large areas quickly with consistent results.

- Dust-Free Operation: When used with a proper vacuum, it’s clean and safe.

- Improved Coating Bond: Roughened profile enhances adhesion for overlays or coatings.

- Cost-Effective: Recyclable shot reduces consumable expenses.

Whether for a small renovation or a major construction job, it ensures optimal surface performance with minimal effort.

Key Factors Affecting the Price of a Concrete Shot Blaster

- Machine Size & Power

Small (5–10 inch): Ideal for home or spot treatments; lower cost

Medium (10–15 inch): Great for commercial projects; good value

Large (20+ inch): Industrial-grade; highest cost - Working Efficiency

Higher square meter output per hour increases performance and price. High-efficiency machines save time and labor. - Power Type

Electric: Quiet, low-maintenance, ideal for indoor use; affordable

Fuel-Powered: Stronger for outdoor use; more expensive

Pneumatic: Designed for explosive or special environments; high-end option - Dust Collection System

With built-in dust collector: Safer and more eco-friendly, but higher cost

Without collector: Requires a separate unit, increasing total investment - Structure & Materials

High-strength steel frames, reinforced bodies, and heavy-duty wheels improve durability but raise the price - Automation Level

Manual: Lower cost, but it depends on the operator’s skill

Automatic/CNC: Easier to operate, higher accuracy and output; higher price - Additional Features

Adjustable speed, blasting depth, quick-change parts, and compatibility with multiple abrasives all add to machine value

Upgrade Concrete Floor Shot Blasting Today!

YG’s advanced pavement shot blasting machines are the ultimate solution for:

Waterproofing and texturing concrete bridge decks

Cleaning and roughening asphalt surfaces for enhanced adhesion

Improving anti-slip performance on roads, tunnels, and bridges

Why Choose YG Shot Blasters?

✔ Industry-leading surface preparation technology

✔ Unmatched efficiency for large-scale projects

✔ Built to withstand heavy-duty industrial use

Transform Your Surface Preparation Today!

Contact us now to get your YG concrete shot blaster and experience:

Faster project completion times

Superior surface quality every time

Long-term cost savings

Leave your requirements below, and our experts will help you select the perfect shot blasting solution for your needs!

WhatsApp/WeChat/Phone: 86 138 3715 9132