What Is A Core Drilling Rig?

A core drilling rig is a specialized drilling machine used to collect cylindrical core samples from beneath the surface. These samples help identify the composition, structure, and strength of subsurface materials. The process is essential in mining, geotechnical surveys, construction, and environmental studies.

The core drilling machine operates by rotating a hollow drill bit that cuts into soil or rock, allowing for the removal of a continuous core. These cores provide valuable data for site evaluation, resource estimation, and risk assessment.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Core Drilling Rig Parameter

| Model | HZ-130Y/130YY | HZ-180Y/180YY | HZ-200Y/200YY |

| Drilling Depth (m) | 130 | 180 | 200 |

| Opening Hole Diameter (mm) | 220 | 220 | 352 |

| End Hole Diameter (mm) | 75 | 75 | 75 |

| Drill Angle (0) | 42-60 | 42-60 | 42-60 |

| Matching Power (kW) | 13.2 | 13.2 | 14.7 |

| Weight Without Power (kg) | 600/740 | 620/750 | 880/970 |

| Dimension (m) | 2.4*0.8*1.4 | 2.4*0.8*1.3 | 2.7*0.9*1.5 |

| Vertical Shaft | |||

| Speed (r/min) | 124/285/570 | 130/300/480/730/830/1045 | 64/128/287/557 |

| Stroke (mm) | 450 | 450 | 450 |

| Winch | |||

| Max. Pull Force (kg) | 2000 | 2100 | 2500 |

| Pull Speed (m/s) | 0.41-1.64 | 0.35-2.23 | 0.12-0.95 |

| Rope Diameter (mm) | 9.3 | 9.3 | 12.5 |

| Roll Capacity (m) | 27 | 27 | 35 |

| Drill Mast | |||

| Rated Load (t) | 18 | 18 | 18 |

| Height (m) | 6.5 | 6.5 | 6.5 |

| Mud Pump | |||

| Flow (L/min) | 95 | 95 | 145 |

| Working Pressure | 1.2mpa | 1.2mpa | 2mpa |

| Reciprocating Times | 93 | 93 | 93 |

| Hose | |||

| Inlet Hose Diameter (mm) | 51 | 51 | 51 |

| Outlet Hose Diameter(mm) | 32 | 32 | 38 |

Why Is Core Sampling Crucial For Mining?

- Reveals mineral deposits and ore boundaries

- Assess ground stability before excavation

- Helps in designing safe and cost-effective mining operations

Core drilling is a foundation of mineral exploration. Without it, decisions would rely on guesswork instead of geological proof.

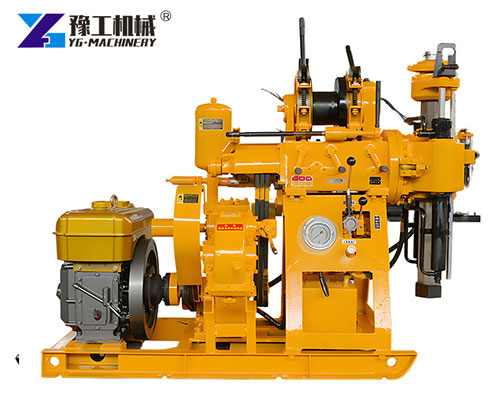

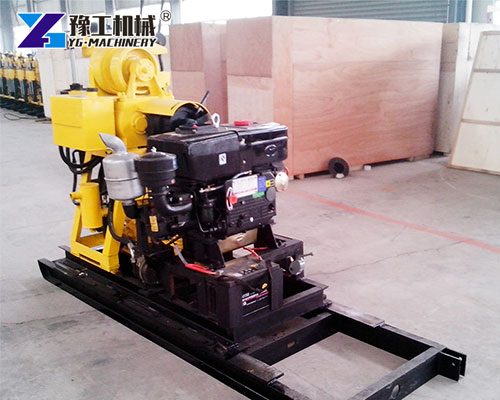

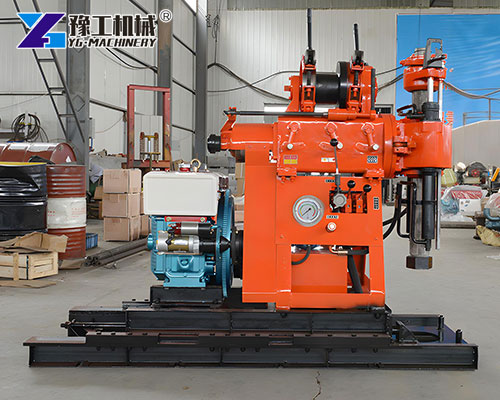

Structure And Features Of A Coring Drill Rig

A coring drill rig typically consists of these main components:

- Drill tower and spindle for vertical movement

- Rotary drive system to rotate the drill bit

- Mud pump system for flushing out debris

- Power unit (diesel or electric)

There are several types of core rigs, but one of the most commonly used is the vertical shaft core drilling rig, known for its simplicity and wide application.

Vertical Shaft Core Drilling Rig: Structure And Working Principle

The vertical shaft type core drilling rig features:

- A vertical spindle connected to a gearbox

- A winch system to lift or lower the drill rod

- A mechanical or hydraulic feed mechanism

- Manual or powered control for speed and pressure

This design ensures a balanced drilling force and easy control during coring.

Key Advantages Over Hydraulic Core Drilling Machine:

| Feature | Vertical Shaft Type | Hydraulic Core Drilling Machine |

|---|---|---|

| Operation | Manual with a low learning curve | Requires professional training |

| Maintenance | Simple and easy to repair | Higher complexity and parts cost |

| Cost | Lower core drill machine price | Higher initial investment |

| Application | Ideal for SPT and soil sampling | Suitable for deeper hard rock drilling |

The hydraulic core drilling machine is great for large-scale exploration, but the vertical shaft type offers excellent value and ease of use for many field jobs.

Special Role In SPT: Standard Penetration Testing

One of the key strengths of vertical shaft rigs is their compatibility with SPT testing.

What Is SPT Testing?

SPT stands for Standard Penetration Test, used in geotechnical engineering to measure the soil’s strength and density. The process includes:

- Driving a split-barrel sampler into the ground using a drop hammer

- Counting the number of blows required for specific depths

- Analyzing the results to evaluate soil compaction and bearing capacity

How Core Drilling Rig Supports Better SPT Testing:

- Steady Drilling Control: Accurate borehole depth and positioning

- Drop Hammer Compatibility: Supports standard SPT tools

- Dual Functionality: Allows soil coring and SPT in one operation

SPT is a standard method in foundation design, and the right coring drill rig enhances both efficiency and accuracy.

Choosing The Right Drill Bit For Soil And Rock

The drill bit plays a crucial role in performance and sample quality.

Types Of Drill Bits:

- Diamond Core Bits

- Best for hard rock

- High cost but long life

- Tungsten Carbide Bits

- Ideal for soft to medium soils

- More affordable and versatile

- Alloy Steel Bits

- Suitable for mixed ground layers

- Balance between durability and price

How To Select The Right Bit:

- Soil Type: Use carbide for clay, diamond for granite

- Project Budget: Match the bit to the expected wear

- Sample Quality: Harder bits give cleaner samples

Correct drill bit selection improves coring accuracy and protects your machine.

Best Practices for Operating And Maintaining A Core Drilling Rig

To ensure long service life and safe operation, follow these practices:

Operation Guidelines:

- Always level the rig before starting

- Monitor feed pressure and torque

- Use the correct drilling fluid based on the soil

Daily Maintenance Tips:

- Check spindle lubrication and replace worn parts

- Clean drilling components after each use

- Inspect hydraulic lines (if applicable)

Safety Notes:

- Wear helmets, gloves, and goggles

- Stop drilling if abnormal vibration occurs

- Never leave the machine running unattended

Tips For Selecting The Right Model

- Match depth to project need

- Consider mobility and weight for remote sites

- Balance features with budget to control your core drill machine price

A well-chosen model saves both time and money.