The Floor shot blaster is a powerful surface preparation machine used to clean, roughen, and profile concrete, steel, and asphalt surfaces. It works by blasting steel shots at high velocity to remove surface contaminants like paint, epoxy, or adhesives, while also creating a textured profile that improves coating adhesion. Whether you’re preparing a warehouse floor, bridge deck, or parking garage, a floor shot blaster ensures speed, precision, and consistent results.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Floor Shot Blaster Parameters:

| Model | YG-270(Single) | YG550/600(Double) | YG-850(Double) | |

| Shot Blasting Wheel Diameter | 200mm | |||

| Working width | 270 mm | 550/600 mm | 800 mm | |

| Walking speed | 0.5~20 m/min | 0.5~33 m/min | ||

| Concrete surface cleaning efficiency | ≥180 m2/h | ≥400 m2/h | ≥600 m2/h | |

| Steel plate surface cleaning efficiency | 15-25 m2/h | 75-100 m2/h | 100-160 m2/h | |

| Dust connection pipe diameter | 120 mm | 150 mm | ||

| Suggest the diameter of steel balls | 1.2-1.5 mm | 1.5-1.8 mm | ||

| Steel pill consumption | 10 g/m2 | |||

| Supporting a dust collector | Seven-core automatic backflush vacuum cleaner | Eight-core automatic backflush vacuum cleaner | ||

| Shot wheel motor | Power consumption | 11 kW | 11*2 kW | 15*2 kW |

| Input Current | ≤ 15 A | ≤ 22*2 A | ≤ 28*2 A | |

| Walking motor | Power consumption | 0.5 kW | 1.5 kW | |

| Input Current | 1 A | 3 A | ||

| Size (mm) | 1000*300*1100 | 1950*720/775*1400 | 1950*1020*1550 | |

| Weight | 150 kg | 570 kg | 700kg | |

| Power connection requirements | 400V, 50Hz, 100A, CEE socket | |||

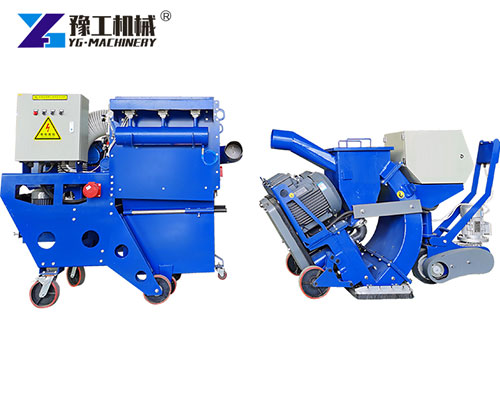

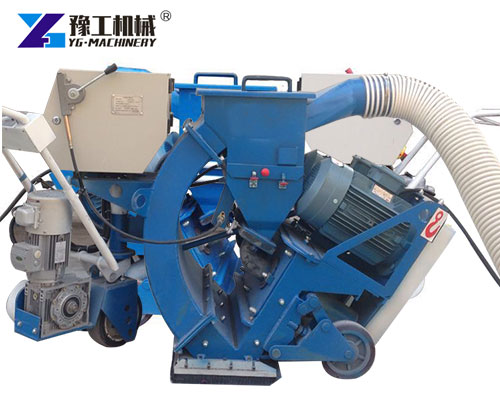

Basic Components of a Floor Shot Blaster

- Blast Wheel: The heart of the machine that propels steel shot at high speed.

- Shot Hopper: Stores and feeds abrasive media into the blast wheel.

- Separation System: Filters reusable shot from dust and debris for continuous operation.

- Dust Collector: Ensures a clean, dust-free work environment.

- Control Panel: Allows operators to manage speed, flow rate, and other functions.

- Drive Motor and Wheels: Enable smooth and controlled movement across surfaces.

Working Principle of a Floor Shot Blaster

- Abrasive Media Feeding: Steel shots are fed into the rotating blast wheel.

- High-Speed Impact: The wheel throws the shots against the floor at high velocity.

- Surface Impact and Cleaning: The impact removes coatings, debris, and weak surface layers.

- Shot Recovery: Used shots, along with dust and debris, are vacuumed into a separation chamber.

- Dust Filtration: Dust is sent to a vacuum system, while clean shots are reused.

Applications of a Concrete Shot Blaster

A concrete shot blaster is ideal for a wide range of industrial, commercial, and infrastructure surface preparation tasks. Common applications include:

- Concrete Surface Preparation: Removes coatings, adhesives, and laitance for better adhesion.

- Steel Deck Blasting: Prepares steel surfaces before painting or coating.

- Airport Runway Cleaning: Improves friction and removes contaminants.

- Bridge Deck Preparation: Cleans and roughens bridge decks before overlay installation.

- Warehouse Floor Resurfacing: Prepares worn concrete floors for new coatings or repairs.

Its effectiveness across various materials makes it a must-have for flooring and coating contractors.

Advantages of Using a Floor Shot Blaster

Choosing a floor shot blaster offers several key benefits that improve efficiency and surface quality:

- Faster Surface Prep: Covers large areas quickly compared to grinding.

- Improved Adhesion: Creates an ideal surface profile for bonding coatings or overlays.

- Environmentally Friendly: A closed-circuit system minimizes dust and debris.

- Cost-Effective: Recycles steel shot for reduced abrasive consumption.

- Lower Maintenance Costs: Durable construction reduces downtime.

These advantages translate into higher productivity, cleaner worksites, and better-quality finishes.

How to Use a Floor Shot Blasting Machine

Using a floor shot blasting machine correctly ensures safety and optimal results. Follow these steps for effective operation:

- Surface Inspection: Check the floor for cracks, loose materials, or hazardous substances.

- Machine Setup: Fill the shot hopper, connect the dust collector, and adjust settings.

- Operation: Start the blast wheel and guide the machine evenly across the surface.

- Speed Control: Adjust the walking speed for the desired texture or removal depth.

- Shot Recovery: Empty the dust collector and refill the hopper as needed.

- Post-Blasting Cleanup: Vacuum remaining dust and check surface quality.

Proper use reduces wear and tear while delivering a consistently clean and textured surface.

Why Choose YG Machinery for Floor Shot Blasters

YG Machinery is a trusted name in industrial equipment manufacturing, offering high-quality floor shot blasters that combine durability, innovation, and value.

Would you like me to include a product comparison chart or usage checklist for visual reference? WhatsApp/WeChat/Phone: 86 138 3715 9132