What Is A Hydraulic Core Drilling Rig?

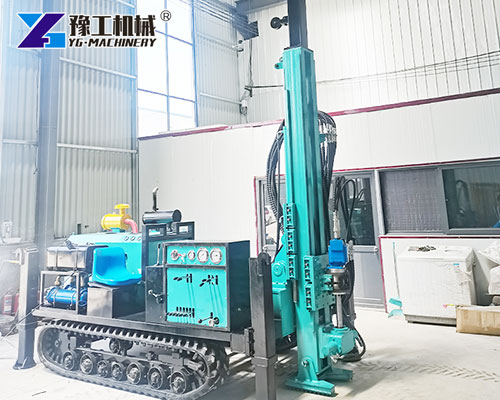

A Hydraulic Core Drilling Rig is a power-driven drilling unit that uses a full hydraulic system to rotate, push, and lift drill strings. It cuts a cylindrical core from rock, soil, or man-made materials for testing and design. The rig in this series is crawler-mounted and supports 400 m / 600 m / 800 m depth options. It is built for high efficiency, strong torque, and clean hydraulic control. Typical uses include geological exploration, mining prospecting, foundation investigation, and small water well projects.

Key highlights at a glance:

- High drilling efficiency with smooth hydraulic feed.

- Strong powertrain for hard formations.

- All-hydraulic controls for precise pressure and speed.

- Crawler undercarriage for tough terrain.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Hydraulic Core Drilling Rig Technical Specifications — 400/600/800 M Class

The following specs are representative and can be customized per project.

| Model | YGX-400 | YGX-600 | YGX-800 | |

| Drilling Depth(M) | 180-400-500 | 200-600-650 | 400-800-1000 | |

| Rated pressure(MPA) | 21 | 21 | 25 | |

| Rated Flow(L/min) | 168 | 192 | 260 | |

| Heat Dissipation Mode | Air cooling+water cooling | |||

| Engine Brand | Yuchai | Yuchai | Yuchai | |

| Rated power/speed | 78kW/ 2400r/min | 92kW/ 2400r/min | 92kW/ 2400r/min | |

| Drilling Angle(°) | 0-90 | 45-90 | 45-90 | |

| Lifting Force(T) | 12 | 16 | 24 | |

| Feed Force(T) | 6 | 8 | 12 | |

| Hydraulic Mud pump flow | 30-90(L/min) | 30-90(L/min) | 90-180(L/min) | |

| Hydraulic Mud pump power | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) | |

| Dimension | 4000*1900*1800mm | 4000*2000*1800mm | 5500*2100*2000mm | |

| Weight | 4.3T | 4.5/5.5T | 6.5T | |

These parameters emphasize deep-hole capability and multi-formation adaptability.

Crawler Core Drilling Machine Features

As a Crawler Core Drilling Machine, the rig moves fast between pads and across uneven ground. The wide tracks lower ground pressure and protect weak surfaces. On steep or muddy access roads, the crawler system keeps traction and balance. For drilling near slopes or riverbanks, the crawler and leveling jacks help set a safe, stable posture. In daily work, operators value how the crawler core drilling machine reduces setup time and towing needs.

- Full Hydraulic Drive: simple controls, smooth load response, and higher efficiency than mechanical feed.

- Crawler Chassis: cross-country mobility; climbs slopes and handles soft ground.

- Multiple Depth Options: choose 400 m, 600 m, or 800 m to match your program.

- Energy-Saving Design: load-sensing hydraulics cut fuel burn; reduced heat improves oil life.

- Stable Mast and Slide: rigid structure keeps alignment for straight, readable cores.

- Quick Service Access: large doors, grouped filters, and easy-reach greasing points.

- Safety Devices: overload protection, emergency stop, hose burst check valves, and night-work lights.

Deep Core Drilling Rig Applications — From Geology To Water Wells

The rig is a Deep Core Drilling Rig designed for continuous penetration at 400, 600, or 800 meters, depending on geology and rod size. High torque at low rpm supports hard formations, while higher rpm helps in soft strata. Long stroke feed and robust pullback help free stuck tools. With correct bit selection and fluid plan, the Hydraulic core drill for Sale maintains a good penetration rate and core recovery, even near maximum design depths. This rig supports a broad range of work:

- Geological Exploration Sampling: obtain NQ/HQ cores for mineral and strata studies.

- Mining Prospecting: confirm ore bodies and grade with reliable core recovery.

- Engineering Geology: foundations, tunnels, and slope assessments.

- Hydrology & Water Wells: slim wells and observation holes with careful control.

- Soil and Weathered Rock: thin-wall barrels and proper bits for clean cores.

The machine is suitable for hard rock, sand layers, gravel zones, and mixed formations often found on large infrastructure sites.

Core Sample Drilling Equipment — Sample Quality First

Accurate data needs intact cores. As core sample drilling equipment, the system focuses on:

- Stable axial feed to avoid core breakage.

- Smooth spindle runout for straight holes.

- Correct flushing for cooling and cutting carry.

- Compatible barrels, shoes, and diamond bits for your lithology.

With these elements aligned, core sample drilling equipment yields readable core boxes that speed up logging and reduce repeat drilling.

Hydraulic Drilling Rig Advantages — Why This Platform Works

- High Drilling Efficiency: faster penetration and fewer trips due to long stroke and strong pullback.

- Adapts To Complex Geology: hard rock, sand, and gravel layers with the right bits and fluids.

- Stable and Safe: rigid mast, reliable clamps, and clear controls.

- Long Duty Cycles: cooling and filtration designed for long shifts and hot climates.

- Lower Total Cost: energy-saving hydraulics and easy maintenance reduce operating expenses.

- Scalable Depth: select 400/600/800 m to match program budgets and goals.

YG Machinery After-Sales Service

- Pre-Job Sizing: choose depth, torque, and rod system based on your geology.

- Training & Commissioning: on-site or remote startup, safety checks, and drilling best practices.

- Spare Parts & Consumables: diamond bits, reaming shells, core barrels, seals, and filters in stock.

- Technical Support: quick responses, troubleshooting guides, and maintenance schedules.

- Documentation: operator manual, hydraulic schematics, and maintenance log templates.

Frequently Asked Questions

Q1: Can one rig handle both 400 m and 800 m jobs?

A: Yes. Choose the 800 m configuration for maximum range, then run lighter strings when working shallower to improve speed.

Q2: What core sizes are common for mineral exploration?

A: NQ and HQ are common. Thin-wall barrels can raise recovery in fragile formations.

Q3: How do you keep cores intact in fractured rock?

A: Use the right bit, maintain steady feed, and ensure proper flushing. Add polymer or adjust fluid viscosity if needed.

Q4: Is transport difficult on rough access roads?

A: The crawler chassis and compact footprint make relocation simpler. Leveling jacks set a stable stance on uneven pads.

Q5: What maintenance matters most?

A: Keep fluids clean and cool, inspect hoses and seals, grease on schedule, and watch filter indicators.

Request A Quote For Hydraulic Core Drilling Rig

Ready to plan your program with a Hydraulic Core Drilling Machine? Send target depth (400/600/800 m), expected core sizes, geology notes, power preference, and site photos. Our engineers will size the head, rods, and hydraulics, recommend the best accessories, and deliver a clear quotation and delivery plan—so your project starts faster, runs safer, and captures high-quality cores.

WhatsApp/WeChat/Phone: 86 138 3715 9132