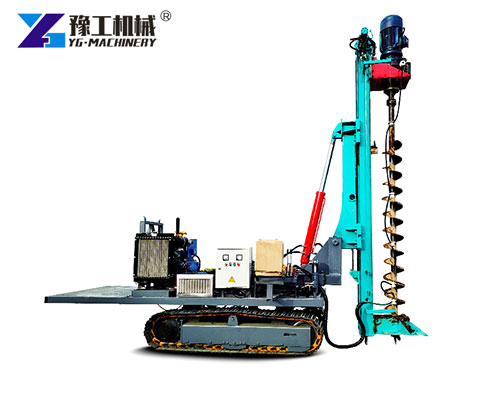

The hydraulic photovoltaic pile driver is a machine used for piling in the construction of photovoltaic power stations. Its main function is to install the supporting piles of the solar panel system to ensure stability. It is specially designed for photovoltaic projects and is an environmentally friendly and efficient solution compared to traditional pile drivers.

WhatsApp/WeChat/Phone/Skype+86 138 3715 9132

Photovoltaic Pile Driver Parameter

| Drilling diameter | 80-500mm | Drilling depth | 0-6m |

| Overall dimensions | 4700*2100*2800mm | Drill pipe rotational speed | 180r/min |

| Track shoe width | 400mm | Gradeability | 30° |

| Motor | 4108 | Rock hardness | 6-20F |

| Drill arm swing angle | left and right 150° | Slide tilt angle | 120° |

| Slide swing angle | left and right 40° | Reducer torque | 13000n.m |

| Mainstream pump | triple pump | Driving speed | 0-3km/h |

| Oil pump | 40/40/32 |

How a Hydraulic Photovoltaic Pile Driver Works

The Hydraulic Photovoltaic Pile Driver operates on the principle of hydraulic power.

Power Source

It is powered by a hydraulic system, which can be driven by an engine or an electric motor. The hydraulic system generates high-pressure fluid to operate the various components of the pile driver.

Pile Gripping

The pile driver has a specialized mechanism to grip the pile firmly. The gripping mechanism secures the pile in place during the driving process and drives it accurately into the ground.

Impact or Rotation

Depending on the type of operation (drilling or ramming), the pile driver either applies a series of impacts to drive the pile into the ground or rotates the pile to drill it in. The hydraulic power is used to generate the necessary force for these actions.

Control System

A control system allows the operator to adjust the speed, force, and other parameters of the pile-driving process. This ensures optimal performance and safety.

The Difference between Drilling and Ramming

Drilling

When using a Photovoltaic Pile Driver for drilling, the pile is rotated into the ground. This method is suitable for softer soil conditions where the pile can be easily drilled. Drilling offers several advantages:

It causes less disturbance to the surrounding soil, which is beneficial for the stability of the photovoltaic installation.

It can achieve more precise depth and angle control, ensuring accurate pile placement.

Ramming

Photovoltaic Pile Driver that uses ramming to apply a series of impacts to drive the pile into the ground. This method better suits harder soil conditions or when operators must install larger piles rapidly. Ramming has its own set of benefits:

It can install piles in a shorter time compared to drilling in some cases.

It can penetrate harder soil layers more effectively.

Features of the Hydraulic Photovoltaic Pile Driver

Precision Positioning

The Solar Pile Driver is engineered with high precision. It allows for the accurate positioning of the piles, which is essential for the proper alignment of solar panels. This precision reduces the risk of panel misalignment and ensures maximum energy capture.

High-Power Performance

As a Hydraulic Pile Driver, it offers high-power performance. The hydraulic system can generate a large amount of force, enabling it to drive piles into various types of soil, from soft sand to hard rock. This high-power capacity ensures reliable and efficient pile installation.

Versatility

The Hydraulic Photovoltaic Pile Driver is a versatile machine. The hydraulic pile driver accommodates various pile types, including steel piles, concrete piles, and ground screws. This versatility makes it suitable for a wide range of photovoltaic projects.

Environmental Friendliness

Compared to some traditional pile-driving methods, the Hydraulic Photovoltaic Pile Driver is more environmentally friendly. It produces less noise and vibration, which reduces the impact on the surrounding environment and nearby communities.

Application of Solar Pile Driver

Large-Scale Solar Farms

In large-scale solar farms, the Hydraulic Photovoltaic Pile Driver plays a crucial role. These farms require a large number of piles to be installed quickly and accurately. The high-power and precision features of the pile driver allow for efficient installation, reducing the overall construction time and cost.

For example, in a 100-megawatt solar farm project, the use of a Hydraulic Photovoltaic Pile Driver can significantly speed up the pile installation process compared to manual or less-efficient methods.

Off-Grid Solar Projects

In off-grid solar projects, where the location may be remote and the soil conditions may vary, the Hydraulic Photovoltaic Pile Driver shows its versatility. It can handle different types of soil, from rocky terrains to sandy deserts. This makes it possible to install solar panels in areas where traditional pile-driving methods may not be feasible.

Advantages of YG Photovoltaic Pile Driver

Quality and Reliability

YG Company builds the Hydraulic Photovoltaic Pile Driver with high-quality materials and components.This ensures its long-term reliability and durability.

YG conducts strict quality control during the manufacturing process, so customers can trust that the pile driver will perform consistently in various working conditions.

Technical Support

YG provides excellent technical support to its customers. Whether it’s installation guidance, maintenance advice, or troubleshooting, YG’s team of experts is always ready to assist.

Customization Options

Understanding that different projects have different requirements, YG offers customization options for its Hydraulic Photovoltaic Pile Driver. Customers can choose the specifications, such as pile-driving force, speed, and control features, according to their specific needs.

WhatsApp/WeChat/Phone/Skype+86 138 3715 9132