An RC drilling machine is designed for projects where accurate ground information matters more than decorative drilling results. It focuses on clean sample return, stable drilling control, and practical field efficiency. This makes it a preferred solution for mineral exploration, geotechnical investigation, and selected water well projects.

Unlike traditional drilling systems, RC drilling machines prioritize sample integrity. Material is collected directly from the drilling point and delivered to the surface with minimal disturbance, helping project teams make faster and more confident decisions.

What Makes an RC Drilling Machine Different

The key difference lies in how samples are handled. An RC drilling machine uses a reverse circulation path that isolates cuttings from surrounding material during transport.

This design helps to:

- Prevent sample mixing between layers

- Reduce moisture and debris contamination

- Keep the sample order clear and traceable

For exploration work, this difference directly affects data accuracy and project value.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Product Parameters of RC Drilling Machine

| Model | YG-300 | YG-600 | YG-1000 |

| Max drilling depth | 300m | 600m | 1000m |

| Drilling diameter | 105-305mm | 105-550mm | 105-800mm |

| Drill rod length | 3m | 6m | 6m |

| Driving efficiency | 10-35m/h | 10-35m/h | 10-35m/h |

| Weight | 11t | 17t | 23t |

| Dimensions | 6.2*1.85*2.8m | 10.5.*2.25*3.3m | 11.5*2.25*3.4 |

| In addition to the above models, customized drilling rigs and accessories are also supported. Some models and parameters will be updated; please refer to the actual quotation. | |||

Working Principle of an RC Drilling Machine

An RC drilling machine operates with a dual-wall drill rod system. Compressed air is injected down through the outer tube, while drilled material is lifted upward through the inner tube.

The working process includes:

- Penetration of soil or rock by the drill bit

- Immediate capture of cuttings at the bit face

- Controlled air lift through the inner tube

- Surface discharge via cyclone or sample box

Because samples do not contact the borehole wall during transport, the method delivers consistent and clean results.

Applications of RC Drilling Machines

Mineral Exploration Drilling

RC drilling machines are widely used in early-stage exploration. They provide fast feedback on ore presence without the cost of diamond coring. This helps companies decide where to focus deeper drilling budgets.

A regional exploration company in Ghana was evaluating a new gold exploration target located away from major infrastructure. The project focused on confirming whether mineralization extended below surface anomalies before investing in expensive core drilling.

At the early exploration stage, the team needed fast and cost-effective sampling across multiple drill points. An RC drilling machine was selected to carry out shallow to medium-depth drilling programs.

Thanks to the reverse circulation system, samples were transported directly to the surface with minimal contamination. This allowed geologists to clearly identify gold-bearing zones and adjust drilling locations quickly.

Compared with conventional rotary drilling previously used in similar projects, the RC drilling machine significantly reduced sample loss and re-drilling. As a result, the exploration campaign was completed ahead of schedule, helping the company make informed decisions about deeper drilling and further investment in the Ghanaian mining project.

Geotechnical Investigation

For foundation studies and infrastructure projects, RC drilling supports soil and rock assessment with reliable depth control and repeatable sampling.

A civil engineering contractor in Burkina Faso was responsible for geotechnical investigations for an infrastructure project involving bridge and road foundations. The site conditions included mixed soil layers, laterite formations, and weathered rock, which made conventional sampling unreliable.

To improve data quality, the contractor deployed an RC drilling machine for ground investigation across the construction area. The reverse circulation drilling method allowed soil and rock cuttings to be collected efficiently without borehole collapse.

The clean and well-separated samples helped engineers accurately determine bearing capacity and identify weak strata. This information played a key role in foundation design and reduced the risk of unexpected ground conditions during construction.

Compared with auger drilling methods previously used on similar projects in Burkina Faso, the RC drilling machine delivered more consistent results and reduced the need for repeated drilling. The investigation phase was completed smoothly, supporting on-time project execution.

Selected Water Well Projects

In deeper or complex formations, RC drilling can be used where sample understanding is required before final well completion.

In a rural agricultural area of Cameroon, a local contractor was commissioned to develop a deep water well to support irrigation and community water supply. The geological profile included alternating layers of sand, clay, and fractured rock.

Before final well construction, the contractor needed reliable data on underground formations and water-bearing layers. An RC drilling machine was used during the exploratory drilling phase to collect representative samples at different depths.

The reverse circulation drilling rig ensured that samples remained clean and traceable, allowing hydrogeologists to accurately identify productive aquifers. This reduced uncertainty and prevented unnecessary over-drilling.

Although RC drilling was not used for the final well installation, it played a critical role in planning. The contractor optimized well depth and casing design based on RC drilling results, improving drilling efficiency and reducing overall project cost in the Cameroon project.

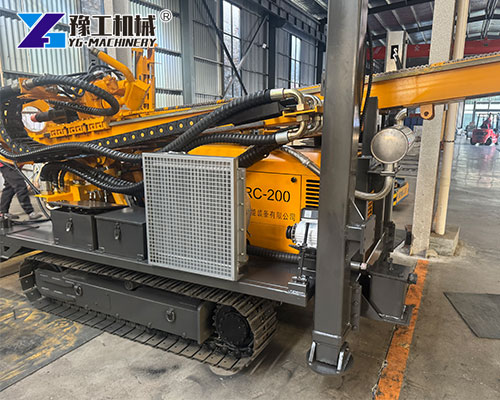

Key System Components of an RC Drilling Machine

A complete RC drilling machine integrates several functional systems:

- Drilling mast and rotary drive unit

- High-capacity air compressor system

- Dual-wall drill rods and inner tube assembly

- Feed system and rod handling structure

- Control panel with safety monitoring

Each system works together to ensure continuous drilling and stable sample return.

RC Drilling Machine Performance Characteristics

An RC drilling machine is valued for balanced field performance rather than extreme specialization.

Key performance traits include:

- Stable penetration speed in mixed formations

- High sample recovery rate

- Reduced downtime from hole cleaning

- Lower need for re-drilling

These traits help control project timelines and operating costs.

When an RC Drilling Machine May Not Be Ideal

Although versatile, RC drilling machines are not universal solutions.

They may be less suitable in cases such as:

- Very loose or collapsing ground where air sealing is difficult

- Extremely deep holes where air pressure becomes inefficient

- Projects with very shallow drilling and limited sampling needs

In these situations, alternative drilling methods may offer better cost performance.

How to Select the Right RC Drilling Machine

Choosing the right RC drilling machine requires matching equipment capability to real project demands.

Important factors include:

- Target drilling depth and hole diameter

- Ground hardness and stability

- Required mobility (crawler, truck-mounted, or trailer type)

- Available fuel or power source

- Sample handling and storage needs

Clear selection criteria reduce overinvestment and improve operational efficiency.

Operational Benefits in Daily Field Use

From an operator’s perspective, RC drilling machines offer practical advantages:

- Cleaner job sites with controlled dust

- Easier sample handling for logging teams

- Fewer interruptions during drilling shifts

- Reduced manpower compared with open-hole methods

These benefits are especially important for long-term exploration programs.

Support and Customization Options

Modern RC drilling machine suppliers often provide more than standard models. Custom options may include:

- Different mast heights

- Adjustable compressor capacity

- Customized rod length and storage

- Optional dust collection systems

Proper configuration improves machine adaptability to local conditions.

Practical Reference for Buyers

An RC drilling machine is best viewed as a precision exploration tool rather than a general-purpose drilling rig. Buyers who understand its strengths and limits can achieve faster results, better data quality, and stronger project control.

For projects where sample accuracy drives decisions, RC drilling remains one of the most cost-effective drilling solutions available.

WhatsApp/WeChat/Phone: 86 138 3715 9132