What Is A Rebar Cutting Machine?

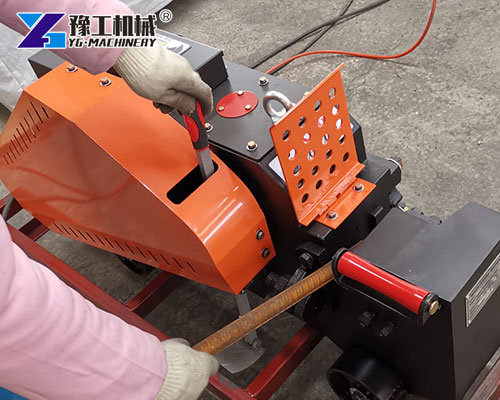

A Rebar Cutting Machine is a purpose-built tool for cutting steel bars to exact lengths. It handles different diameters, from small stirrups to heavy main bars, and supports plain round bar and deformed rebar.

On busy jobsites and in rebar fabrication shops, an Automatic Steel Bar Cutter lifts speed and accuracy. Operators set the length, place the bars, and the machine makes clean, square cuts that help with fast tying, welding, or mechanical couplers. With automatic cycles, one person can manage loading and unloading while the cutter works continuously. This means less waiting, fewer errors, and stable quality across the whole project.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of Rebar Cutting Machine

| Model | Technical Parameter | |

| YG-40/YG-40S | Motor Power(kW) | 2.2 |

| Rebar Diameter(mm) | 6-25 | |

| Round Bar Diameter(mm) | 6-26 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 300 | |

| Dimension(mm) | 1200*310*630 | |

| YG-40A | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-28 | |

| Round Bar Diameter(mm) | 6-35 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 330 | |

| Dimension(mm) | 1310*460*760 | |

| YG-40B | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-35 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 350 | |

| Dimension(mm) | 1310*460*760 | |

| YG-42 | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 380 | |

| Dimension(mm) | 1330*460*790 | |

| YG-45 | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 400 | |

| Dimension(mm) | 1330*460*790 | |

| YG-50 | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-40 | |

| Round Bar Diameter(mm) | 6-45 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 480 | |

| Dimension(mm) | 1410*460*810 | |

| YG-40 Straight Thread Rebar | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-28 | |

| Round Bar Diameter(mm) | 6-35 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 370 | |

| Dimension(mm) | 1330*460*790 | |

| YG-45 Straight Thread Rebar | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 410 | |

| Dimension(mm) | 1330*460*790 | |

| YG-50 Straight Thread Rebar | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-40 | |

| Round Bar Diameter(mm) | 6-50 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 510 | |

| Dimension(mm) | 1410*460*810 | |

| YG-50 Angled Steel Bar | Motor Power(kW) | 4 |

| Angled Bar Diameter(mm) | ≤100*100*10 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 580 | |

| Dimension(mm) | 1440*460*810 | |

| YG-50 Flat Steel Bar | Motor Power(kW) | 4 |

| Flat Bar Diameter(mm) | 150*10 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 580 | |

| Dimension(mm) | 1440*460*810 | |

Main Features Of Automatic Steel Bar Cutter

A modern automatic cutter focuses on productivity and safety. Key features include:

- High Cutting Efficiency — supports continuous batch cutting with steady cycle time.

- Wide Diameter Range — handles straight bar and deformed rebar; multiple blade sets for different sizes.

- Automatic Control System — programmable length and count reduces manual steps and operator fatigue.

- Rugged Structure — thick frame, hardened gears, and high-strength blades for long life in harsh environments.

- Stable Drive — electric or hydraulic drive gives smooth force and consistent cut faces.

- Safety Design — protective covers, emergency stop, and two-hand controls on selected models.

In daily work, these functions keep output high while protecting the operator and the blades.

Construction Rebar Cutting Equipment

On the jobsite, teams prefer construction rebar cutting equipment that is compact, easy to move, and fast to set up. These cutters can sit near the pour or the tying area to avoid long carrying distances.

What sets construction rebar cutting equipment apart:

- Mobility: wheels or forklift slots for quick relocation around the site.

- Power Flexibility: 220–240 V or 380–415 V; some models support generators.

- Simple Controls: clear levers or push buttons; short training time.

- Tough Build: dust-resistant covers and reinforced frames for outdoor work.

These features help crews keep up with schedule changes and reduce rebar bottlenecks before steel fixing.

Types Of Automatic Rebar Cutting Machine

Different models fit different workloads and power needs. The main categories are:

- Plant-Grade Cutter (Industrial):

- High-power electric or hydraulic drive.

- Suited for thick diameters and long shifts.

- Often paired with measuring tables and conveyors.

- On-Site Cutter (Construction):

- Compact body with wheels or a skid base.

- Quick to deploy near the forming area.

- Balanced for common sizes used in slabs, beams, and columns.

- Drive Variants:

- Electric Motor: simple, cost-effective, minimal maintenance.

- Hydraulic Drive: higher cutting force at low speed, steady performance on large bars.

Choose the model that matches your daily tonnage, main bar sizes, and power source.

Advantages Of Using A Steel Bar Processing Machine

Switching from handheld tools to a dedicated cutter brings visible gains:

- Save Labor Costs: one operator can manage continuous cutting with pre-set lengths.

- Boost Work Efficiency: faster cycles help crews reach daily steel targets.

- Clean, Flat Cut Faces: better for tying, welding, and couplers; improves connection quality.

- Fewer Errors: automatic length and count reduce measuring mistakes.

- Durable And Low Maintenance: hardened gears, quality bearings, and accessible lubrication points.

Over a project, these benefits shorten schedules and stabilize costs.

Applications Of Automatic Steel Rod Cutter

An automatic steel rod cutter supports many construction scenarios:

- Building Construction: beams, columns, slabs, and shear walls.

- Bridge Projects: pier caps, decks, and approach slabs.

- Highways and Metro: tunnels, stations, retaining walls, and ramp structures.

- Rebar Fabrication Shops: batch cutting by bar lists for delivery to multiple sites.

On complex projects, an automatic steel rod cutter helps teams deliver the right bar, at the right length, at the right time.

Why Choose YG Rebar Cutting Machine

Contractors and fabricators select YG for performance, value, and support:

- Wide Model Range: from portable site cutters to heavy Rebar Cutting Machine lines for plants.

- Global Exports: proven quality in multiple countries and climates.

- Easy Installation and Commissioning: quick setup with guidance videos and manuals.

- After-Sales Service: fast spare parts, blade kits, and remote support.

- Fair Pricing And Quick Lead Time: balanced cost with durable build and reliable delivery.

YG can also align the cutter with bending machines and bar lists to create a streamlined processing cell.

Practical Selection Tips For Your Rebar Cutting Machine

To pick the right capacity and drive:

- Main Bar Sizes: list the largest diameter and volume per day.

- Throughput Goal: estimate tons per shift to size motor and gearbox.

- Power Conditions: Confirm site voltage or generator output.

- Mobility Needs: choose wheels for site use or a fixed frame for plant lines.

- Integration: consider tables, length stops, or bundle handling if you run a shop.

A well-matched Rebar Cutting Machine will meet today’s tasks and scale for future projects.

Request A Quote For Rebar Cutting Machine

Ready to speed up steel work with an Automatic Steel Bar Cutter? Send your bar diameters, daily tonnage, power supply, and mobility needs. Our team will recommend the best Rebar Cutting Machine, share detailed parameters and blade options, and provide a clear price and lead time—so your crew can cut faster, safer, and at a lower cost.

WhatsApp/WeChat/Phone: 86 138 3715 9132