What Is a Road Core Drilling Machine?

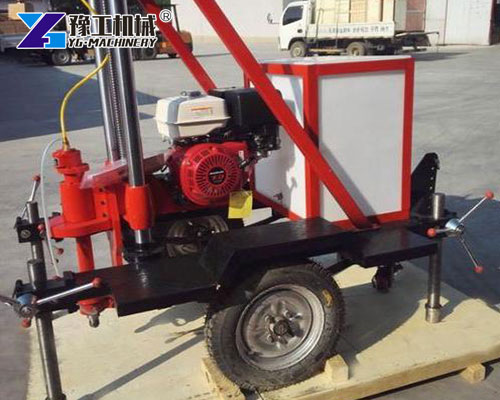

A road core drilling machine is a tool used to cut and collect samples from road surfaces. It is made for asphalt and concrete roads. Engineers use it to test road quality in highways, airports, and city roads.

This machine uses a hydraulic system and a diamond drill bit. It cuts clean core samples without damage. These samples are used to check material strength and aging.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Road Core Drilling Machine Parameter

Road core drilling hydraulic

Maximum speed: 80 km/h, 100 km/h on request

4-stroke engine power: 23 HP

Drive torque: 190 Nm up to 550 rpm; 170 Nm up to 800 rpm

Water tank volume: 400 L

Fuel tank volume: 20 L

Oil tank volume: 70 L

Drill bit connection: 4” UNC

Drilling diameter: 80-250mm, optional maximum 300-330mm

Drilling feed: 600mm

Total weight: 1300kg

Working Principle of Hydraulic Coring Machine

The hydraulic coring machine uses hydraulic power to spin the diamond drill bit. It drills through the pavement with speed and force. A lifting system moves the bit up and down.

- A diamond core bit cuts the material accurately

- The hydraulic motor gives strong and smooth torque

- The vertical guide keeps the drilling straight

- Cooling water prevents overheating and cracking

Common sample sizes: Φ100mm, Φ150mm (also supports Φ50–200mm range).

Key Features of Road Core Drilling

- High Precision: Smooth and undisturbed core samples help in lab testing

- Powerful Hydraulic System: Cuts dense asphalt or concrete with ease

- Mobile & Easy to Operate: Comes with wheels or cart base for easy site movement

- Durable & Low Maintenance: Thick steel frame with anti-rust paint ensures long use

- Versatile Core Diameter Range: Supports different drill bit sizes for flexible needs

Asphalt Core Drilling Machine Applications & Use Cases

- Asphalt pavement core sampling

- Airport runway maintenance testing

- Road foundation quality inspection

- Concrete bridge core extraction

- Third-party testing service for road projects

Concrete Coring Machine Price Guide

Price depends on these factors:

- Drilling depth (standard or deep core)

- Drive method (electric, hydraulic)

- Motor power (1.5kW to 5.5kW options)

- Whether drill bits are included

Advice for Buyers:

- Light use: choose electric with a ≤150mm core size

- Frequent testing: choose hydraulic with quick setup

- On-site field work: use mobile units with built-in wheels

Core Drilling Machine for Road Testing: Why Choose Us?

- 20+ years of focus on pavement testing equipment

- Exported to 30+ countries across Europe, the Middle East, and Southeast Asia

- CE & ISO certified products

- Full pre-sales technical support and training

- Spare parts are available for fast replacement

- Custom branding, packaging, and color accepted

Core Drilling Rig for Pavement Sampling: Customer Reviews & Case Studies

USA: Tennessee DOT bought 3 machines for road inspection. They reported stable drilling and low repair costs.

Philippines: An Independent lab used the machine for expressway sampling. Increased efficiency and accuracy by 40%.

Customer Feedback Highlights:

- Clean core samples

- Easy maintenance

- Reliable performance in tough conditions

Want a reliable road core drilling machine at a fair price?

WhatsApp/WeChat/Phone: 86 138 3715 9132