The screw air compressor is an industrial machine that compresses air using a rotary screw mechanism, instead of pistons. It’s designed for continuous, high-volume air supply and is widely used in manufacturing, construction, automotive, and energy sectors. Unlike piston compressors, screw compressors deliver a steady stream of compressed air with less noise, fewer vibrations, and higher energy efficiency. WhatsApp/WeChat/Phone +86 138 3715 9132

Screw Air Compressor Parameters

| Model | LGPM-10HP |

| Power | 7.5KW |

| Airflow | 1.1 m³/min |

| Pressure | 8 bar |

| Oil (liter) | 12 |

| Noise decibel | 60–70 dB |

| Dimensions | 780 × 600 × 1020 mm |

| Weight (kg) | 215 |

How Rotary Screw Air Compressor Works

At the heart of a screw compressor are two interlocking helical screws (rotors). As they rotate:

Air enters the compression chamber through the inlet valve.

The rotors trap and compress the air as it moves down the length of the screws.

Compressed air exits through the outlet, ready for industrial use or storage in a tank.

Key Features Of The Screw Driven Air Compressor

Modern Screw Driven Air Compressors are designed with several features that improve performance and lower operational costs. These include:

- Continuous Operation: Capable of running 24/7 without loss of performance.

- Energy Efficiency: Variable speed drives help optimize energy use depending on air demand.

- Low Noise: Enclosed designs reduce noise levels, making them suitable for indoor use.

- Compact Structure: Space-saving designs simplify installation in tight work areas.

- Minimal Maintenance: Fewer moving parts reduce wear and simplify maintenance.

Application of Industrial Screw Compressor

Manufacturing Industry

In the manufacturing sector, Screw Compressors are used in a wide variety of applications. They power pneumatic tools like drills, grinders, and impact wrenches, enabling workers to perform tasks quickly and efficiently. People also use compressed air from these compressors to operate conveyor systems, automate production processes, and control robotic arms.

Construction Industry

Construction sites rely heavily on compressed air for various operations. Screw Compressors are used to power jackhammers, nail guns, and paint sprayers, making construction work faster and more efficient. They also provide the air needed for concrete spraying, sandblasting, and operating pneumatic hoists.

Advantages of Rotary Screw Air Compressors

- Continuous Operation

Suitable for 24/7 use with minimal downtime. - Low Vibration and Noise

Compared to piston compressors, they are much quieter. - Compact and Efficient

High output from a smaller footprint. - Longer Lifespan

Fewer moving parts and smooth operation reduce wear. - Lower Maintenance

Especially for oil-free and VSD models with advanced monitoring. - Energy Savings

VSD compressors can reduce electricity use by 30% or more.

How To Choose The Right Screw Air Compressor

- Air Demand: Determine the required CFM (cubic feet per minute) based on the tools or systems the compressor will support.

- Pressure Requirements: Consider the PSI (pounds per square inch) needed for your applications.

- Operating Environment: Indoor vs. outdoor use will affect whether you need noise reduction, mobility, or environmental protection.

- Oil-Injected vs. Oil-Free: Choose based on air quality needs—oil-free models are essential for contaminant-sensitive industries.

- Budget & Energy Consumption: Higher initial investment in efficient models can save energy and costs long-term.

Understanding your operational needs will help ensure you choose a model that offers both performance and cost-effectiveness. For example: Industrial Portable Air Compressor

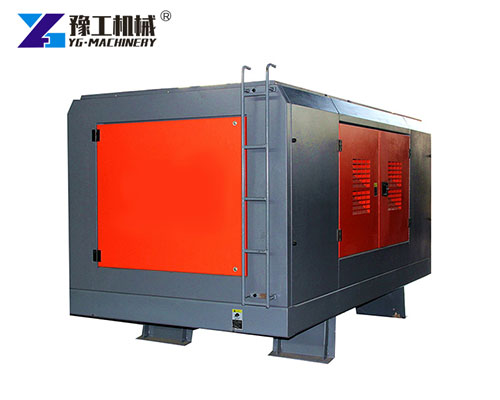

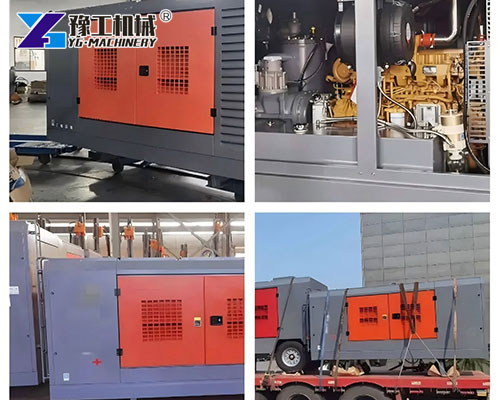

Screw Air Compressor from YG Machinery

The Screw Air Compressor from YG has gained wide market recognition for its excellent performance and stable quality. It utilizes advanced screw compression technology, offering a dependable air source for diverse pneumatic equipment. Moreover, Screw Compressor is outfitted with an intelligent control system. This system can make automatic adjustments based on actual demand, thereby improving energy utilization efficiency. Whether in the manufacturing field or the chemical industry, the Screw Compressor Air by YG is capable of meeting your requirements and facilitating more efficient production.

WhatsApp/WeChat/Phone +86 138 3715 9132