What Is a Water Well Drill Pipe?

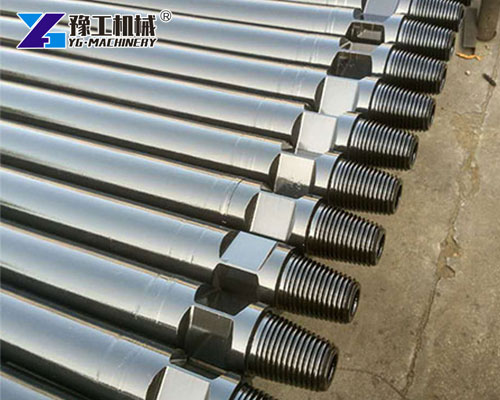

A Water Well Drill Pipe for Sale is a critical component in borehole drilling operations. It is a long, tubular steel pipe used to connect the drilling rig at the surface with the drill bit below. The drill pipe transmits the rotary torque, drilling fluid, and axial force required to penetrate different soil layers and reach underground water sources.

Each section is threaded to enable fast connection and disconnection during drilling operations, making it ideal for both shallow and deep water well projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Function and Importance of Water Well Drill Pipe

The Water Well Drill Pipe serves multiple essential functions that ensure the stability and performance of the drilling operation:

- Transmits Power: Transfers the rotational and pushing force from the rig to the drill bit.

- Circulates Drilling Fluid: Allows fluid (mud or water) to flow to the drill bit for cooling, cleaning, and removing cuttings.

- Supports Weight: Carries the weight of the drilling equipment and supports torque transmission.

- Modular Assembly: Enables incremental depth drilling by adding more pipe sections.

Choosing a reliable pipe minimizes downtime, prevents bending or breakage, and ensures the borehole remains on track.

Specifications of Drill Pipe for Sale

| Diameter | Thread | Wall thickness | Length | Wrench flats | Weight | ||||

| Inch | mm | Inch | mm | Feet | m | Inch | Mm | Kg | |

| 3 | 76 | 2 3/8″ | 0.217 | 5.5 | 4.92 | 1.5 | 2.244 | 57 | 22 |

| 3 | 76 | 2 3/8″ | 0.217 | 5.5 | 6.56 | 2 | 2.244 | 57 | 26 |

| 3 | 76 | 2 3/8″ | 0.217 | 5.5 | 9.84 | 3 | 2.244 | 54 | 35 |

| 3.5 | 89 | 2 3/8″ | 0.335 | 8.5 | 9.84 | 3 | 2.559 | 65 | 66 |

| 3.5 | 89 | 2 3/8″ | 0.335 | 8.5 | 13.12 | 4 | 2.559 | 65 | 79 |

| 3.5 | 89 | 2 3/8″ | 0.335 | 8.5 | 14.76 | 4.5 | 2.559 | 65 | 85.5 |

| 3.5 | 89 | 2 3/8″ | 0.335 | 8.5 | 16.4 | 5 | 2.559 | 65 | 92 |

| 3.5 | 89 | 2 3/8″ | 0.335 | 8.5 | 19.69 | 6 | 2.559 | 65 | 105 |

| 4 | 102 | 2 3/8″,2 7/8″ | 0.335 | 8.5 | 9.84 | 3 | 2.992 | 76 | 72 |

| 4 | 102 | 2 3/8″,2 7/8″ | 0.335 | 8.5 | 13.12 | 4 | 2.992 | 76 | 92 |

| 4 | 102 | 2 3/8″,2 7/8″ | 0.335 | 8.5 | 14.76 | 4.5 | 2.992 | 76 | 101 |

| 4 | 102 | 2 3/8″,2 7/8″ | 0.335 | 8.5 | 16.4 | 5 | 2.992 | 76 | 130 |

| 4 | 102 | 2 3/8″,2 7/8″ | 0.335 | 8.5 | 19.69 | 6 | 2.992 | 76 | 150 |

Types of Water Well Drill Pipe

There are several classifications of Water Well Drill Pipe based on materials, structure, and specific applications. Understanding these helps in selecting the right pipe for your drilling conditions.

Material Options

- Carbon Steel: Offers an excellent strength-to-weight ratio, ideal for most water well drilling tasks.

- Alloy Steel: Contains chromium, molybdenum, and other elements for enhanced wear and corrosion resistance.

- Stainless Steel: Best for high-corrosion environments or when clean water contact is essential.

Structural Variations

- Friction Welded Drill Pipes: Known for strength and precision alignment.

- Threaded-End Pipes: Most common, compatible with standard drill rig threads (API REG, API IF).

- Integral Joint Pipes: Include the tool joint and pipe body as one solid piece for higher durability.

Specialty Drill Pipes

- Non-Magnetic Drill Pipes: For projects involving sensitive directional sensors.

- Reverse Circulation Pipes: For dual-wall circulation during special borehole applications.

- Heavy Weight Drill Pipe (HWDP): Used when transitioning from drill collars to regular drill pipes for shock absorption.

Water Well Drill Pipe for Sale: How to Choose the Right One

When browsing Water Well Drill Pipe for sale, buyers should consider operational requirements and geological conditions. Here are a few tips:

- Depth of Drilling: Deeper wells require stronger pipes with better tensile and compressive strength.

- Formation Hardness: Rockier terrain may need alloy steel or thicker-walled pipes.

- Rig Compatibility: Ensure thread type and length match the rig’s spindle and chuck design.

- Budget vs. Lifespan: Higher initial costs may lead to lower maintenance and longer lifespan.

A proper match reduces the risk of failure and enhances drilling efficiency.

Maintenance Tips for Extended Drill Pipe Life

Proper maintenance of the Water Well Drill Pipe can significantly increase its lifespan and ensure smooth drilling operations.

Routine Maintenance Includes:

- Regular Inspections: Check for bending, corrosion, and joint thread wear after each job.

- Thread Protection: Use thread protectors during transport and storage.

- Cleaning: Flush internal bores after use to remove drilling debris and chemicals.

- Lubrication: Apply pipe dope to threads before assembly to prevent galling and corrosion.

- Storage: Stack in dry, shaded areas on flat surfaces to avoid warping and surface rust.

Routine checks not only prevent equipment failure but also save long-term repair costs.

Drill Rod for Sale: Understanding Compatibility

When evaluating a Drill Rod for Sale, it’s essential to understand how it fits into your existing system. Drill rods are often used interchangeably with drill pipes, especially in portable rigs.

Key factors to check:

- Diameter and Length: Match with your rotary head and tower clearance.

- Thread Type: Standard API threads (e.g., NC, REG) vs. proprietary threads.

- Weight and Wall Thickness: Impacts drilling depth and torque transfer.

Pairing your Water Well Drill Pipe with a compatible drill rod ensures seamless performance and fewer complications.

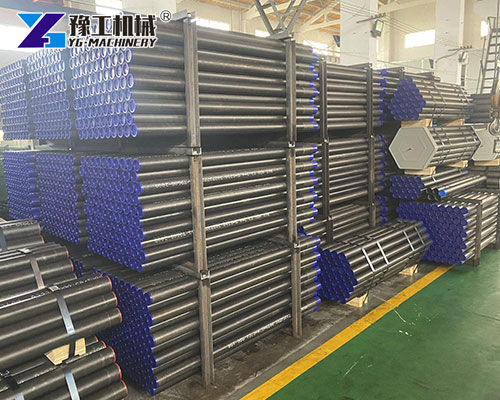

YG Machinery: Trusted Drill Pipe Manufacturer

YG Machinery offers a full range of Water Well Drill Pipe options tailored to meet diverse drilling requirements across the globe. Known for quality control and precision engineering, YG pipes are trusted by professionals in the water well, geothermal, and mining industries.

Why Choose YG Machinery:

- High-grade steel with heat treatment for extra durability.

- Thread precision machining to ensure tight connections.

- Custom pipe lengths and diameters based on drilling needs.

- Bulk inventory and fast shipping to support urgent projects.

- Competitive pricing and global support from our expert team.

Whether you’re drilling a residential water well or managing a commercial borehole operation, YG provides the tools to get the job done efficiently and reliably.

WhatsApp/WeChat/Phone: 86 138 3715 9132