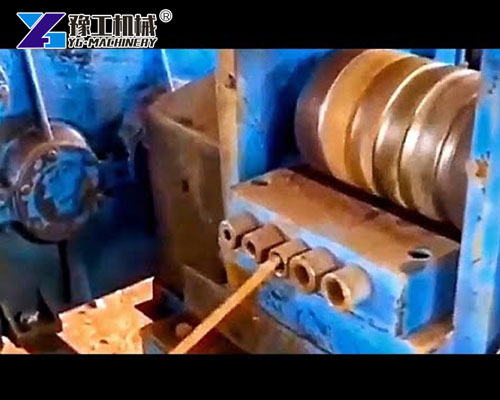

The steel bar straightening machine is an industrial device designed to correct bends, twists, or deformations in steel bars, ensuring they meet precise dimensional standards. These machines play a vital role in industries like construction, automotive manufacturing, and metal fabrication, where straight bars are critical for structural integrity, assembly accuracy, and product reliability. WhatsApp/WeChat/Phone: 86 138 3715 9132

Steel Bar Straightening Machine Models

| Model | YG 4-8 | YG 4-12 | YG 6-14 | YG 10-25 |

| Processing diameter | 4-8mm | 4-12mm | 6-14mm | 10-25mm |

| Minimum processing distance | 300mm | 300mm | 300mm | 300mm |

| Motor power | 5.5KW | 5.5KW | 5.5KW | 15KW |

| Dimensions | 1500*500*1100mm | 1500*850*1100mm | 1150*720*1200mm | 1400*1000*1350mm |

| Machine weight | 450kg | 600kg | 550kg | 830 |

Key Factors Influencing Results

- Bar Diameter: Thicker bars require higher pressure (e.g., 200 tons for 40 mm rebar).

- Material Hardness: High-carbon steel needs 30% more force than mild steel.

- Machine Settings: Speed, roller gap, and pressure must align with bar specifications.

Benefits of Using a Steel Bar Straightening Machine

Faster Production

Automate the straightening process to handle 50–100 bars per hour, compared to 10–15 with manual labor. This cuts labor costs by 40% and reduces project timelines, allowing factories to meet tight deadlines for large-scale infrastructure projects.

Cost Savings

Minimize material waste by reducing scrap rates by 25%, as fewer bent bars require reprocessing. For a mid-sized factory processing 1,000 tons monthly, this could save over $15,000 annually in raw material costs alone.

Consistency

Automated systems guarantee uniform straightness across every batch, crucial for mass production of standardized parts like rebar for concrete or automotive axles. This eliminates human error, ensuring compliance with ISO 9001 or ASTM standards.

Improved Logistics

Straight bars stack compactly, saving 30% storage space and simplifying transport. Neatly aligned bars reduce loading/unloading time by half and minimize damage during shipping, enhancing supply chain efficiency.

Rebar Straightening And Cutting Machine Applications

In modern industrial and construction sectors, rebar straightening and cutting machines have become indispensable for precision metalworking.

Construction Industry

These machines ensure rebars meet exact specifications for reinforced concrete structures. For high-rise buildings, bridges, and tunnels, straightened rebars enhance structural integrity in pillars, slabs, and foundations. Automated cutting minimizes material waste, crucial for large-scale projects like dam construction or subway systems.

Automotive Manufacturing

Precision-straightened steel rods are vital for suspension systems, axle shafts, and chassis components. In electric vehicle production, evenly cut rebars improve battery frame durability. A European car manufacturer reduced assembly errors by 18% after adopting automated rebar processing.

Metal Fabrication Workshops

Before welding or machining custom parts, such as industrial machinery frames or safety railings, rebars must be flawlessly straight. The machines also prepare materials for CNC processes, ensuring consistency in components like conveyor belt supports or agricultural equipment.

Architectural and Furniture Design

Designers use these machines to craft sleek, load-bearing metal frames for modern furniture. Examples include cantilevered tables, modular shelving units, and artistic stair railings. A New York studio credits the technology for enabling intricate geometric designs in luxury retail displays.

Shipbuilding and Offshore Platforms

Marine-grade stainless steel rebars, straightened and cut to exact lengths, reinforce hulls and oil rig foundations. The machines withstand corrosive environments, ensuring longevity in saltwater applications.

Renewable Energy Infrastructure

Wind turbine bases and solar farm mounting systems rely on precision-cut rebars. A German wind energy firm cut installation time by 25% using pre-processed, site-ready rebar segments.

Steel Bar Straightening Machine Manufacturer

YG Machinery offers a comprehensive range of steel bar machinery, including rebar straightening and cutting machines, bending machines, thread rollers, and beam benders. Our rebar processing machines for sale are engineered for precision, durability, and efficiency, trusted by clients globally in the construction, manufacturing, and infrastructure sectors.

With ISO-certified quality control and a skilled engineering team, we deliver reliable equipment backed by 24/7 technical support. Whether you need an automatic steel bar cutting machine for high-volume projects or specialized tools like thread rebar couplers, we provide tailored solutions. Contact us today to discuss your requirements and benefit from our industry-leading expertise and after-sales service.

WhatsApp/WeChat/Phone: 86 138 3715 9132